Abstract

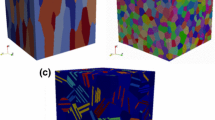

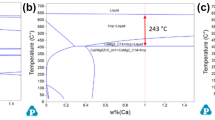

In order to facilitate the optimization of the casting process for the large-scaled complex titanium alloy casting (LCTAC), a quantification and statistical analysis method for the LCTAC was developed to elucidate the distribution characteristics of microstructure and mechanical properties throughout the entire casting. The homogeneity coefficient was employed to investigate the relationships between casting structural features and the homogeneity of microstructure-properties. The findings indicate a skewed distribution of grain size in the whole casting, with a notable linear positive correlation between grain size distribution characteristics and wall thickness. Correspondingly, a mere 90% reduction in wall thickness leads to more than a 10% increase in strength or hardness. Furthermore, a comparative analysis revealed that the microstructure homogeneity coefficient for wall thickness exhibited a significant influence of over 50% compared to the homogeneity attributed to wall position, suggesting that wall thickness exerts a more pronounced impact on the homogeneity of LCTAC.

Graphical Abstract

Similar content being viewed by others

Data Availability

The authors do not have permission to share data.

References

B.-C. Yang, S.-F. Chen, H.-W. Song, S.-H. Zhang, H.-P. Chang, S.-W. Xu, Z.-H. Zhu, C.-H. Li, Effects of microstructure coarsening and casting pores on the tensile and fatigue properties of cast A356–T6 aluminum alloy: a comparative investigation. Mater. Sci. Eng. A. 857, 144106 (2022). https://doi.org/10.1016/j.msea.2022.144106

J. Jiang, J. Yan, Y. Liu, G. Hu, Y. Wang, C. Ding, D. Zou, Investigation on heat treatment of large-sized and complex AlSi9Mg aluminum alloy components formed by squeeze casting. J. Alloys Compd. 924, 166504 (2022). https://doi.org/10.1016/j.jallcom.2022.166504

J. Wu, Y. Chen, Z. Du, H. Jiang, Modeling of investment casting of Ti48Al48Cr2Nb2 (at%) alloy air rudder skeleton. Int. J. Metalcast. (2022). https://doi.org/10.1007/s40962-022-00907-5

Z. Niu, G. Liu, T. Li, S. Ji, Effect of high pressure die casting on the castability, defects and mechanical properties of aluminium alloys in extra-large thin-wall castings. J. Mater. Process. Technol. 303, 117525 (2022). https://doi.org/10.1016/j.jmatprotec.2022.117525

S.-Y. Sung, Y.-J. Kim, Alpha-case formation mechanism on titanium investment castings. Mater. Sci. Eng., A 405, 173–177 (2005). https://doi.org/10.1016/j.msea.2005.05.092

I. Khaled, Prediction of shrinkage porosity in Ti–46Al–8Nb tilt-casting using the Niyama criterion function. Int. J. Metalcast. 7, 35–42 (2013). https://doi.org/10.1007/BF03355562

J. Yang, Y. Wu, R. Hu, Z. Gao, Fabrication and microstructure optimization of TiAl castings using a combined melting/pouring/heat treatment device. Int. J. Metalcast. 15, 890–898 (2021). https://doi.org/10.1007/s40962-020-00525-z

G.K. Upadhya, S. Das, U. Chandra, A.J. Paul, Modelling the investment casting process: a novel approach for view factor calculations and defect prediction. Appl. Math. Model. 19, 354–362 (1995). https://doi.org/10.1016/0307-904X(95)90001-O

S. Milenkovic, I. Sabirov, J. LLorca, Effect of the cooling rate on microstructure and hardness of MAR-M247 Ni-based superalloy. Mater. Lett. 73, 216–219 (2012). https://doi.org/10.1016/j.matlet.2012.01.028

R.A. Harding, M. Wickins, H. Wang, G. Djambazov, K.A. Pericleous, Development of a turbulence-free casting technique for titanium aluminides. Intermetallics 19, 805–813 (2011). https://doi.org/10.1016/j.intermet.2010.11.022

M. Alizadeh, Correlation between the continuous casting parameters and secondary dendrite arm spacing in the mold region. Mater. Lett. 91, 146–149 (2013). https://doi.org/10.1016/j.matlet.2012.09.108

C.D. Ridgeway, C. Gu, K. Ripplinger, D. Detwiler, M. Ji, S. Soghrati, A.A. Luo, Prediction of location specific mechanical properties of aluminum casting using a new CA-FEA (cellular automaton-finite element analysis) approach. Mater. Des. 194, 108929 (2020). https://doi.org/10.1016/j.matdes.2020.108929

V.S. Saravanan, C. Palanisamy, M. Mohanraj, J. Shah, S. Bhero, A study on relationship between casting geometric modulus and feeding distance of ductile iron bar-shaped castings. Int. J. Metalcast. 10, 477–482 (2016). https://doi.org/10.1007/s40962-016-0056-0

W.E. Warriner, C.A. Monroe, Locating solidification hot spots and feeder positions in casting geometries by image analysis. Int. J. Metalcast. 12, 224–234 (2018). https://doi.org/10.1007/s40962-017-0167-2

K.D. Carlson, C. Beckermann, Prediction of shrinkage pore volume fraction using a dimensionless Niyama criterion. Metall. Mater. Trans. A. 40, 163–175 (2009). https://doi.org/10.1007/s11661-008-9715-y

A.A. Luo, A.K. Sachdev, D. Apelian, Alloy development and process innovations for light metals casting. J. Mater. Process. Technol. 306, 117606 (2022). https://doi.org/10.1016/j.jmatprotec.2022.117606

X. Cheng, C. Yuan, D. Shevchenko, P. Withey, The influence of mould pre-heat temperature and casting size on the interaction between a Ti–46Al–8Nb–1B alloy and the mould comprising an Al2O3 face coat. Mater. Chem. Phys. 146, 295–302 (2014). https://doi.org/10.1016/j.matchemphys.2014.03.026

A. Pourfathi, R. Tavakoli, Thermal optimization of secondary cooling systems in the continuous steel casting process. Int. J. Therm. Sci. 183, 107860 (2023). https://doi.org/10.1016/j.ijthermalsci.2022.107860

X. Feng, J. Qiu, Y. Ma, J. Lei, Y. Cui, X. Wu, R. Yang, Influence of processing conditions on microstructure and mechanical properties of large thin-wall centrifugal Ti–6Al–4V casting. J. Mater. Sci. Technol. 32, 362–371 (2016). https://doi.org/10.1016/j.jmst.2015.12.010

X. Chamorro, N. Herrero-Dorca, P.P. Rodríguez, U. Andrés, Z. Azpilgain, α-Case formation in Ti–6Al–4V investment casting using ZrSiO4 and Al2O3 moulds. J. Mater. Process. Technol. 243, 75–81 (2017). https://doi.org/10.1016/j.jmatprotec.2016.12.007

T. Wang, X. Shen, J. Zhou, Y. Yin, X. Ji, Q. Zhou, Optimal gating system design of steel casting by fruit fly optimization algorithm based on casting simulation technology. Int. J. Metalcast. 13, 561–570 (2019). https://doi.org/10.1007/s40962-018-0291-7

T. Wang, J. Zhou, L. Wang, Z. Zhang, H. Zhang, X. Xia, Research and development of gating and riser process optimization integrated system for steel casting. Int. J. Metalcast. (2023). https://doi.org/10.1007/s40962-023-00982-2

C.R. Loper Jr., M. Copur, R.M. Kotschi, Analysis of the solidification order in selected casting sections. AFS Trans. 94, 529–536 (1986)

Q. Li, J. Xie, J. Yu, N. Sheng, D. Shu, G. Hou, J. Li, X. Sun, Y. Zhou, Effect of casting thickness on microstructure and mechanical properties of the high-W superalloy K416B. Mater. Today Commun. 29, 102916 (2021). https://doi.org/10.1016/j.mtcomm.2021.102916

K. Wang, B. Liu, Q. Wang, R. Bao, Macrostructures and mechanical properties in laser melting deposited titanium alloy plate at different thickness positions. Mater. Sci. Eng. A. 832, 142433 (2022). https://doi.org/10.1016/j.msea.2021.142433

Z. Xia, Y. Cui, Y. Shen, M. Arroussi, R. Liu, L. Yang, Q. Jia, R. Yang, Tensile properties of Ti–48Al–2Cr–2Nb alloy having similarly oriented lamellae with fine lamellar spacing facilitated by suction casting. Mater. Sci. Eng. A. 830, 142303 (2022). https://doi.org/10.1016/j.msea.2021.142303

X. Chang, G. Chen, W. Sun, H. Zhang, G. Chu, X. Zhang, F. Han, W. Zhang, Z. Du, Microstructures, mechanical properties and solidification mechanism of a hot tearing sensitive aluminum alloy asymmetric part fabricated by squeeze casting. J. Alloys Compd. 886, 161254 (2021). https://doi.org/10.1016/j.jallcom.2021.161254

W. Jiang, Z. Fan, X. Chen, B. Wang, H. Wu, Combined effects of mechanical vibration and wall thickness on microstructure and mechanical properties of A356 aluminum alloy produced by expendable pattern shell casting. Mater. Sci. Eng., A 619, 228–237 (2014). https://doi.org/10.1016/j.msea.2014.09.102

A. Zaitzeff, A. Pilchak, T. Berman, J. Allison, S. Esedoglu, A robust algorithm to calculate parent β grain shapes and orientations from α phase electron backscatter diffraction data in α/β-titanium alloys. Scr. Mater. 191, 191–195 (2021). https://doi.org/10.1016/j.scriptamat.2020.09.038

D. Zhao, G. Wu, Effects of remelting and refining on the microstructure and properties of particle reinforced magnesium-lithium matrix composites. Mater. Sci. Eng. A. 788, 139607 (2020). https://doi.org/10.1016/j.msea.2020.139607

J.M. Marín, M.T. Rodríguez-Bernal, Multiple hypothesis testing and clustering with mixtures of non-central t-distributions applied in microarray data analysis. Comput. Stat. Data Anal. 56, 1898–1907 (2012). https://doi.org/10.1016/j.csda.2011.11.016

Y. Sun, H. Fujii, Effect of abnormal grain growth on microstructure and mechanical properties of friction stir welded SPCC steel plates. Mater. Sci. Eng., A 694, 81–92 (2017). https://doi.org/10.1016/j.msea.2017.04.008

Acknowledgement

This work was supported by the Special Research Project of Chinese Civil Aircraft (MJZ-2014-G-25).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yu, W., Qie, X., Zhao, W. et al. Effect of Structural Features on Microstructure and Properties Homogeneity Based on Quantification and Statistical Analysis for Large-Scaled Complex Titanium Alloy Castings. Inter Metalcast 18, 1535–1546 (2024). https://doi.org/10.1007/s40962-023-01135-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-023-01135-1