Abstract

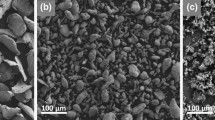

This research presents a novel approach to overcome the stress shielding effect and non-degradability commonly observed in metallic implants, which often require revision surgery. The study introduces a hybrid metal/ceramic (Ti/HA) reinforcement within the Mg-3Zn binary alloy matrix fabricated using the squeeze casting technique. The alloy matrix incorporates 1 wt% Ti and varying weight percentages (0.5, 1, and 1.5 wt%) of hydroxyapatite (HA). Microstructure analysis revealed significant grain refinement in the alloy upon adding the hybrid reinforcement. Phase analysis using XRD confirmed the presence of Mg-Zn intermetallic phases and corresponding reinforcement phases. Vickers microhardness testing demonstrated a 14.4% (89 HV) increase in hardness for the hybrid composite with 1Ti/1.5HA compared to the unreinforced alloy and other composites. Compressive testing revealed enhanced mechanical properties in the hybrid composites. The 1Ti/1.5 HA hybrid composite displayed a 12% (121 MPa) increase in compressive yield strength (CYS) compared to the alloy, while the 1Ti/1HA hybrid composite exhibited an impressive 22.5% (217 MPa) increment in compressive strength. Corrosion performance evaluation in a phosphate-buffered saline (PBS) environment indicated that the 1Ti/1.5 HA hybrid composites demonstrated comparable corrosion performance to the unreinforced alloy, with a corrosion density of 4.53 × 10−5 μA/cm2 and a linear polarization resistance of 893 ohms. Based on the findings, the Mg-3Zn alloy with 1Ti/1.5 HA hybrid reinforcement emerges as a promising material for load-bearing biodegradable implants.

Similar content being viewed by others

References

S.P. Ramachandran Krishnan, Biodegradable magnesium metal matrix composites for biomedical implants: synthesis, mechanical performance, and corrosion behavior -a review. J. Market. Res. 20, 650–670 (2022). https://doi.org/10.1016/j.jmrt.2022.06.178

M.H.-A. Murad Ali, Magnesium-based composites and alloys for medical applications: a review of mechanical and corrosion properties. J. Alloy. Compd. 792, 1162–1190 (2019). https://doi.org/10.1016/j.jallcom.2019.04.080

M.A. Hussein, M.A. Azeem, A.M. Kumar, N.M. Emara, Processing and in vitro corrosion analysis of sustainable and economical eggshell reinforced Mg and Mg-Zr matrix composite for biomedical applications. Mater. Today Commun. 32, 103944 (2022). https://doi.org/10.1016/j.mtcomm.2022.103944

D.L. Yan Huang, Fabrication and characterization of a biodegradable Mg–2Zn–0.5Ca/1β-TCP composite. Mater. Sci. Eng., C 54, 120–132 (2015). https://doi.org/10.1016/j.msec.2015.05.035

H.Z. Tao Li, Microstructure, mechanical properties and in vitro degradation behavior of a novel biodegradable Mg–1.5Zn–0.6Zr–0.2Sc alloy. J. Mater. Sci. Technol. 31(7), 744–750 (2015). https://doi.org/10.1016/j.jmst.2015.02.001

R.M. Satish Jaiswal, Mechanical, corrosion and biocompatibility behaviour of Mg-3Zn-HA biodegradable composites for orthopaedic fixture accessories. J. Mech. Behav. Biomed. Mater. 78, 442–454 (2017). https://doi.org/10.1016/j.jmbbm.2017.11.030

L.D. Yang Min, Microstructure and properties of Mg-3Zn- 02Ca alloy for biomedical application. Rare Metal Mater. Eng. 47(1), 0093–0098 (2018). https://doi.org/10.1016/S1875-5372(18)30078-X

D.L. Guangyi Lin, Preparation and characterization of biodegradable Mg-Zn-Ca/MgO nanocomposites for biomedical applications. Mater. Charact. 144, 120–130 (2018). https://doi.org/10.1016/j.matchar.2018.06.028

G.X. Debao Liu, Fabrication of biodegradable HA/Mg-Zn-Ca composites and the impact of heterogeneous microstructure on mechanical properties, in vitro degradation and cytocompatibility. Bioelectrochemistry 129, 106–115 (2019). https://doi.org/10.1016/j.bioelechem.2019.05.001

S.N. Rodzi, H. Zuhailawati, B.K. Dhindaw, Mechanical and degradation behaviour of biodegradable magnesium–zinc/hydroxyapatite composite with different powder mixing techniques. J. Magn. Alloys 7, 566–576 (2019). https://doi.org/10.1016/j.jma.2019.11.003

B.E. Sahar Mokhtari, Synthesis and characterization of biodegradable AZ31/calcium phosphate glass composites for orthopedic applications. Adv. Compos. Hybrid Mater. 3, 390–401 (2020). https://doi.org/10.1007/s42114-020-00177-x

N. Pulido-González, B. Torres, P. Rodrigo, N. Hort, J. Rams, Microstructural, mechanical and corrosion characterization of an as-cast Mg–3Zn–0.4Ca alloy for biomedical applications. J. Magn. Alloys 8(2), 510–522 (2020). https://doi.org/10.1016/j.jma.2020.02.007

R.K. Pooja Rai, To develop biodegradable Mg-based metal ceramic composites as bone implant material. Bull. Mater. Sci. 43, 227 (2020). https://doi.org/10.1007/s12034-020-02191-7

Y. Hu, X. Guo, Y. Qiao, X. Wang, Q. Lin, Preparation of medical Mg–Zn alloys and the effect of different zinc contents on the alloy Biomater. Synthes. Characterization 33, 9 (2022). https://doi.org/10.1007/s10856-021-06637-0

Y. Leiting, S. Lyu, Y. Chen, C. You, Y. Zhao, M. Chen, Simultaneously improving the mechanical property and corrosion resistance of extruded biomedical Mg–3Zn alloy by forming in-situ MgO. J. Mater. Res. Technol. 18, 2977–2992 (2022). https://doi.org/10.1016/j.jmrt.2022.03.173

S. Ouyang, Y. Liu, Q. Huang, Z. Gan, H. Tang, Effect of composition on in vitro degradability of Ti–Mg metal-metal composites. Mater. Sci. Eng.: C 107, 110327 (2020). https://doi.org/10.1016/j.msec.2019.110327

A.K. Khanra, Microstructure and mechanical properties of Mg-HAP composites. Bull. Mater. Sci. 33, 43–47 (2010). https://doi.org/10.1007/s12034-010-0006-z

Y.C.-D. Xiaopeng Wang, Effects of Sn content on the microstructure, mechanical properties and biocompatibility of Ti–Nb–Sn/hydroxyapatite biocomposites synthesized by powder metallurgy. Mater. Des. 49, 511–519 (2013). https://doi.org/10.1016/j.matdes.2013.01.012

S. Sankaranarayanan, S. Jayalakshmi, M. Gupta, Hybridizing micro-Ti with nano-B4C particulates to improve the microstructural and mechanical characteristics of Mg–Ti composite. J. Magn. Alloys 2(1), 13–19 (2014). https://doi.org/10.1016/j.jma.2014.03.001

J. Sun, M. Chen, The effect of nano-hydroxyapatite on the microstructure and properties of Mg–3Zn–05Zr alloy. J. Compos. Mater. 48(7), 825–834 (2014). https://doi.org/10.1177/0021998313478259

B. Chen, K.Y. Yin, T.F. Lu, B.Y. Sun, Q. Dong, J.X. Zheng, C. Lu, Z.C. Li, AZ91 magnesium alloy/porous hydroxyapatite composite for potential application in bone repair. J. Mater. Sci. Technol. 32, 858–864 (2016). https://doi.org/10.1016/j.jmst.2016.06.010

A.A. Reza Rahmany-Gorji, Microstructure and mechanical properties of stir cast ZX51/Al2O3p magnesium matrix composites. Mater. Sci. Eng. A 674, 413–418 (2016). https://doi.org/10.1016/j.msea.2016.07.057

W.L. Zeqin Cui, Effect of nano-HA content on the mechanical properties, degradation and biocompatible behavior of Mg-Zn/HA composite prepared by spark plasma sintering. Mater. Charact. 151, 620–631 (2019). https://doi.org/10.1016/j.matchar.2019.03.048

R. Radha, D. Sreekanth, Mechanical and corrosion behaviour of hydroxyapatite reinforced Mg-Sn alloy composite by squeeze casting for biomedical applications. J. Magn. Alloys 8(2), 452–460 (2020). https://doi.org/10.1016/j.jma.2019.05.010

X. Song, P. Bayati, M. Gupta, M. Elahinia, M. Haghshenas, Fracture of magnesium matrix nanocomposites - a review. Int. J. Lightweight Mater. Manufact. 4(1), 67–98 (2021). https://doi.org/10.1016/j.ijlmm.2020.07.002

B. Vinod, M. A., Dry sliding wear mechanisms of incorporated hydroxyapatite waste materials: synthesis and characterization of magnesium hybrid composites. Trans. Indian Inst. Met. 73, 3037–3057 (2020). https://doi.org/10.1007/s12666-020-02103-7

S.J. Huang, M. Subramani, C.C. Chiang, Effect of hybrid reinforcement on microstructure and mechanical properties of AZ61 magnesium alloy processed by stir casting method. Compos. Commun. 25, 100772 (2021). https://doi.org/10.1016/j.coco.2021.100772

G.L. Yunting Guo, The microstructure, mechanical properties, corrosion performance and biocompatibility of hydroxyapatite reinforced ZK61 magnesium-matrix biological composite. J. Mech. Behav. Biomed. Mater. 123, 104759 (2021). https://doi.org/10.1016/j.jmbbm.2021.104759

D. Ahmadkhaniha, M. S., Corrosion behavior of magnesium and magnesium–hydroxyapatite composite fabricated by friction stir processing in Dulbecco’s phosphate buffered saline. Corros. Sci. 104, 319–329 (2016). https://doi.org/10.1016/j.corsci.2016.01.002

H. Zengin, Role of Sr in microstructure, hardness and biodegradable behavior of cast Mg–2Zn–2Ca–0.5Mn (ZXM220) alloy for potential implant application. Int. J. Met. 14(2), 442–453 (2020). https://doi.org/10.1007/s40962-019-00366-5

H. Mohammadi, M. Emamy, Z. Hamnabard, The statistical analysis of tensile and compression properties of the as-cast AZ91-X%B4C composites. Int. J. Met. 14(2), 505–517 (2020). https://doi.org/10.1007/s40962-019-00377-2

J. Bian et al., Research on the effect of Sr and Zr on microstructure and properties of Mg–4Zn alloy. Int. J. Met. 15(4), 1483–1498 (2021). https://doi.org/10.1007/s40962-021-00576-w

M. Razzaghi, M. Kasiri-Asgarani, H.R. Bakhsheshi-Rad, H. Ghayour, Microstructure, mechanical properties, and in-vitro biocompatibility of nano-NiTi reinforced Mg–3Zn-05 Ag alloy: prepared by mechanical alloying for implant applications. Compos. Part B: Eng. 190, 107947 (2020). https://doi.org/10.1016/j.compositesb.2020.107947

Acknowledgment

Authors would like to acknowledge the Department of Manufacturing Engineering, FEAT, Annamalai University, Chidambaram, for providing facilities to carry over this research work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

Authors declare that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Vignesh, P., Ramanathan, S., Ashokkumar, M. et al. Microstructure, Mechanical, and Electrochemical Corrosion Performance of Ti/HA (Hydroxyapatite) Particles Reinforced Mg-3Zn Squeeze Casted Composites. Inter Metalcast 18, 1348–1360 (2024). https://doi.org/10.1007/s40962-023-01114-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-023-01114-6