Abstract

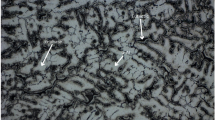

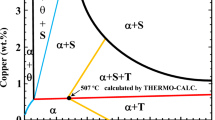

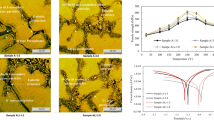

This research paper examines the effect of different solution heat treatments parameters (temperature and time) on Al–3.39%Cu–2.26%Mg (wt%) alloy’s microstructure, thermal, mechanical and corrosion properties. 5754 alloy and Al–Cu alloy are used to make Al–3.39%Cu–2.26%Mg (wt%) by gravity die casting. Solution heat treatment at different temperature and time (500 °C-10 min, 500 °C-4h, 530 °C-10 min and 530 °C-2h). As-cast Al–Cu–Mg alloy have α-phase and eutectic phase. After solution heat treatment and aging, precipitates phases is observed in microstructure. X-ray diffraction analysis results have shown that a precipitate phase [S phase (Al2CuMg)] gets formed in as-cast conditions but undergoes dissolution during the solution heat treatment process. As-cast Al–Cu–Mg alloy has a Brinell hardness value of 77.2 HB. As-cast alloy has S (Al2CuMg) precipitate phase increases hardness by precipitation strengthening. After solution heat treatment and aging, Brinell hardness reduces. After solution heat treatment (500 °C for 4 h) and aging (200 °C for 5 h), Brinell hardness values becomes 63.6 HB (− 17.6% decrease). Corrosion resistance improves after the solution heat treatment due to the dissolution of the precipitate phase, forming an almost single-phase solid solution. The as-cast alloy exhibits a peak compressive stress of 494.2 MPa, which increases after solution heat treatment and water quenching to 572.7 MPa (without aging). After aging, peak compressive stress decreases to 508.4 MPa. Failure strain for the as-cast alloy is 39.6%, reducing to 31.1% after solution heat treatment and water quenching. It again increases to 43.1% after aging.

Similar content being viewed by others

References

İ Özbek, A study on the resolution heat treatment of AA 2618 Aluminum alloy. Mater. Charact. 58(3), 312–317 (2007). https://doi.org/10.1016/j.matchar.2006.07.002

J. Jang et al., Effect of solution treatment and artificial aging on microstructure and mechanical properties of Al–Cu alloy. Trans. Nonferr. Met. Soc. China 23(3), 631–635 (2013). https://doi.org/10.1016/S1003-6326(13)62509-1

Y. Xu et al., Experimental research on creep aging behavior of Al–Cu–Mg alloy with tensile and compressive stresses. Mater. Sci. Eng. A 682, 54–62 (2017). https://doi.org/10.1016/j.msea.2016.11.043

G. Bo et al., Static softening behavior and modeling of an Al–Cu–Mg–Zr alloy with various pre-precipitation microstructures during multistage hot deformation. Mater. Sci. Eng. A 778, 139094 (2020). https://doi.org/10.1016/j.msea.2020.139094

M. Zamani, S. Toschi, A. Morri et al., Optimisation of heat treatment of Al–Cu–(Mg–Ag) cast alloys. J. Therm. Anal. Calorim. 139, 3427–3440 (2020). https://doi.org/10.1007/s10973-019-08702-x

N. Chobaut et al., Characterisation of precipitation upon cooling of an AA2618 Al–Cu–Mg alloy. J. Alloys Compd. 654, 56–62 (2016). https://doi.org/10.1016/j.jallcom.2015.09.113

S.C. Wang, M.J. Starinks, Two types of S phase precipitates in Al–Cu–Mg alloys. Acta Mater. 55(3), 933–941 (2007). https://doi.org/10.1016/j.actamat.2006.09.015

M.F. Ibrahim et al., A preliminary study on optimizing the heat treatment of high strength Al–Cu–Mg–Zn alloys. Mater. Des. 57, 342–350 (2014). https://doi.org/10.1016/j.matdes.2013.11.078

I. Zuiko, R. Kaibyshev, Aging behavior of an Al–Cu–Mg alloy. J. Alloys Compd. 759, 108–119 (2018). https://doi.org/10.1016/j.jallcom.2018.05.053

J.-H. Jang et al., Effect of solution treatment and artificial aging on microstructure and mechanical properties of Al–Cu alloy. Trans. Nonferr. Met. Soc. China 23(3), 631–635 (2013). https://doi.org/10.1016/S1003-6326(13)62509-11

Y. Deng, L. Wan, Y. Zhang, X. Zhang, Evolution of microstructures and textures of 7050 Al alloy hot-rolled plate during staged solution heat-treatments. J. Alloys Compd. 498(1), 88–94 (2010). https://doi.org/10.1016/j.jallcom.2010.03.117

M. Zamani et al., Optimisation of heat treatment of Al–Cu–(Mg–Ag) cast alloys. J. Therm. Anal. Calorim. 139(6), 3427–3440 (2020). https://doi.org/10.1007/s10973-019-08702-x

N. Nafsin, H.M.M.A. Rashed, Effects of copper and magnesium on microstructure and hardness of Al–Cu–Mg alloys. Int. J. Eng. Adv. Technol. 2(5), 533–536 (2013)

O. Engler, C.D. Marioara, T. Hentschel, H. Brinkman, Influence of copper additions on materials properties and corrosion behaviour of Al–Mg alloy sheet. J. Alloys Compd. 710, 650–662 (2017). https://doi.org/10.1016/j.jallcom.2017.03.298

G. Bo et al., Static softening behavior and modeling of an Al–Cu–Mg–Zr alloy with various pre-precipitation microstructures during multistage hot deformation. Mater. Sci. Eng. A 778(2020), 139094 (2020). https://doi.org/10.1016/j.msea.2020.139094

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Patel, N., Joshi, M., Singh, A. et al. Effect of Solution Heat Treatment (Temperature and Time) on Microstructure and Properties of Al–Cu–Mg Alloy. Inter Metalcast 18, 1151–1159 (2024). https://doi.org/10.1007/s40962-023-01095-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-023-01095-6