Abstract

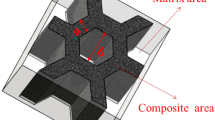

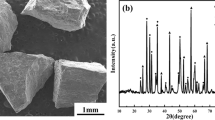

Composites of honeycomb-structured high-chromium cast iron matrix reinforced with zirconia-toughened alumina particles (ZTAP) were successfully fabricated by a non-pressure infiltration casting process. Different preform hole patterns were designed in this study, following the principle of keeping the same area of the honeycomb holes with the same outline size. The hardness and modulus continuously increased from the high-chromium cast iron matrix through the interfacial layer to the ZTA ceramic particle. The residual thermal stress in the samples with the circle hole pattern was the lowest at 389.7 ± 20.2 MPa. The wearing volume loss of the composites with the regular hexagon pattern was minimal after four periods.

Similar content being viewed by others

References

Q. Dong, H. Li, S. Xing et al., Effect of casting pressure on microstructure and anti-abrasion property of KmTBCr26 white cast iron. Inter. Metalcast. (2022). https://doi.org/10.1007/s40962-022-00789-7

F. Wang, L. Xu, Microstructure and erosion wear characterization of a new cast high-vanadium-chromium alloy (HVCA). Inter. Metalcast. (2022). https://doi.org/10.1007/s40962-022-00787-9

B. Zheng, W. Li, X. Tu et al., Effect of titanium binder addition on the interface structure and three-body abrasive wear behavior of ZTA ceramic particles-reinforced high chromium cast iron. Ceram. Int. 46(9), 13798–13806 (2020). https://doi.org/10.1016/j.ceramint.2020.02.169

Sui Y, Zhou M, Jiang Y, et al. Characterization of interfacial layer of ZTA ceramic particles reinforced iron matrix composites. Journal of Alloys and Compounds, 2018: 1169-1174. https://doi.org/10.1016/j.jallcom.2018.01.199

Z. Özdemir, Shallow cryogenic treatment (SCT) effects on the mechanical properties of high cr cast iron: low-carbon cast steel bimetallic casting. Inter. Metalcast. 15, 952–961 (2021). https://doi.org/10.1007/s40962-020-00532-0

J. Wan, A. Van, J. Qing et al., A comparison of adhesive wear with three-body abrasive wear characteristics of graphitic white irons designed for metal-to-metal wear systems. Inter. Metalcast. 15, 447–458 (2021). https://doi.org/10.1007/s40962-020-00502-6

A. Schulte, Quality improvements of cast lightweight steel P900 armor. Inter. Metalcast. 4, 59–63 (2010). https://doi.org/10.1007/BF03355487

N. Przyszlak, T. Wrobel, A. Dulska, Influence of molding materials on the self-hardening of X46Cr13 steel/grey cast iron bimetallic casting. Arch. Metall. Mater. 66(1), 43–50 (2021)

A. Dulska, J. Szajnar, M. Krol, Analysis of the mechanical properties of the titanium layer obtained by the mold cavity preparation method. Arch. Metall. Mater. 66(1), 43–50 (2021)

K. Zheng, Y. Gao, S. Tang et al., Interface structure and wear behavior of Cr26 ferrous matrix surface composites reinforced with CTCP. Tribol. Lett. 54(1), 15–23 (2014). https://doi.org/10.1007/s11249-014-0303-6

H. Nakae, Y. Hiramoto, Spontaneous infiltration of Al melts into SiC preform. Inter. Metalcast. 5, 23–28 (2011). https://doi.org/10.1007/BF03355469

B. Vuksanovich, J. Chavez, C. Gygi et al., Non-destructive inspection of sacrificial 3d sand-printed molds with geometrically complex lattice cavities. Inter. Metalcast. 16, 1091–1100 (2022). https://doi.org/10.1007/s40962-021-00681-w

J. Du, X. Chong, Y. Jiang et al., Numerical simulation of mold filling process for high chromium cast iron matrix composite reinforced by ZTA ceramic particles. Int. J. Heat Mass Trans. (2015). https://doi.org/10.1016/j.ijheatmasstransfer.2015.05.046

J. Ru, Y. Jia, Y. Jiang et al., Modification of ZTA particles with Ni coating by electroless deposition. Surf. Eng. 33(5), 353–361 (2017). https://doi.org/10.1080/02670844.2016.1248119

M. Zhou, Y. Sui, X. Chong et al., Wear resistance mechanism of ZTAP/HCCI composites with a honeycomb structure. Metal 8, 588 (2018). https://doi.org/10.3390/met8080588

K. Zheng, Y. Gao, Y. Li et al., Three-body abrasive wear resistance of iron matrix composites reinforced with ceramic particles. Proc. IMechE Part J. J. Eng. Tribol. 228(1), 3–10 (2014). https://doi.org/10.1177/1350650113496700

B. Qiu, S. Xing, Q. Dong, Fabrication and wear behavior of ZTA particles reinforced iron matrix composite produced by flow mixing and pressure compositing. Wear (2019). https://doi.org/10.1016/j.wear.2019.03.013

P. Li, J. Gao, M. Gong et al., Effects of manganese on diffusion and wear behavior of ZTA particles reinforced iron matrix composites in vacuum. Vacuum (2020). https://doi.org/10.1016/j.vacuum.2020.109408

S.L. Tang, Y.M. Gao, Y.F. Li et al., Recent developments in fabrication of ceramic particle reinforced iron matrix wear resistant surface composite using infiltration casting technology. Ironmak. Steelmak. 41(8), 633–640 (2014). https://doi.org/10.1179/1743281213Y.0000000175

J. Zhang, Y. Sui, Y. Jiang et al., Effect of honeycomb structure parameters on the mechanical properties of ZTAp/HCCI composites. Mater. Res. Exp. (2022). https://doi.org/10.1088/2053-1591/ac6ccf

G. Niu, Y. Sui, H. Zeng et al., Effect of centrifugal casting temperature on the microstructure and properties of ZTA(P)/HCCI matrix composites. Mater. Res. Exp. 8(2), 026513 (2021). https://doi.org/10.1088/2053-1591/abe012

Y. Zhao, Z. Li, Y. Li et al., Effect of soften annealing on the machinability and bonding stability of ZTA ceramic particles reinforced HCCI composite. Mater. Lett. 323, 132553 (2022). https://doi.org/10.1016/j.matlet.2022.132553

H. Mei, X. Zhao, S. Zhou, D. Han, S. Xiao, L. Cheng, 3D-printed oblique honeycomb Al2O3/SiCw structure for electromagnetic wave absorption. Chem. Eng. J. 372, 940–945 (2019). https://doi.org/10.1016/j.cej.2019.05.011

Y. Wang, S. Tan, D. Jiang et al., The effect of porous carbon preform and the infiltration process on the properties of reaction-formed SiC. Carbon 42(8), 1833–1839 (2004). https://doi.org/10.1016/j.carbon.2004.03.018

M. Zhou, Y. Jiang, Y. Sui et al., Microstructure and properties of interfacial transition zone in ZTA particle-reinforced iron composites. Appl. Phys. A 125(2), 110 (2019). https://doi.org/10.1007/s00339-018-2365-z

D. Xue, Y. Jia, X. Zhang et al., Effect of ZTA volume fractions on the microstructure and properties of ZTAp/high manganese steel composites. Mater. Res. Exp. 6(4), 046535 (2019). https://doi.org/10.1088/2053-1591/aafbf2

C. Li, Y. Li, J. Shi et al., Interfacial characteristics and wear performances of iron matrix composites reinforced with zirconia-toughened alumina ceramic particles. Ceram. Int. 48(1), 1293–1305 (2022). https://doi.org/10.1016/j.ceramint.2021.09.214

J. Hashim, L. Looney, M.S. Hashmi et al., Particle distribution in cast metal matrix composites-part I. J. Mater. Process. Technol. 123(2), 251–257 (2002). https://doi.org/10.1016/S0924-0136(02)00098-5

J. Hashim, L. Looney, M.S. Hashmi et al., Particle distribution in cast metal matrix composites—part II. J. Mater. Process. Technol. 123(2), 258–263 (2002). https://doi.org/10.1016/S0924-0136(02)00099-7

O. Elkady, A. Fathy, Effect of SiC particle size on the physical and mechanical properties of extruded Al matrix nanocomposites. Mater. Des. (2014). https://doi.org/10.1016/j.matdes.2013.08.049

J. Segurado, C. Gonzalez, J. Llorca et al., A numerical investigation of the effect of particle clustering on the mechanical properties of composites. Acta Mater. 51(8), 2355–2369 (2003). https://doi.org/10.1016/S1359-6454(03)00043-0

K. Abd El-Aziz, D. Saber, A.A. Megahed, Investigation and prediction of abrasive wear rate of heat-treated HCCIs with different Cr/C ratios using artificial neural networks. Int. J. Metalcast. 15(4), 1149–1163 (2021). https://doi.org/10.1007/s40962-020-00547-7

Kh. Abd El-Aziz, Kh. Zohdy, D. Saber et al., Wear and corrosion behavior of high-Cr white cast iron alloys in different corrosive media. J. Bio. Tribo. Corros. (2015). https://doi.org/10.1007/s40735-015-0026-8

Kh. Abd El-Aziz, D. Saber, Erratum to Mechanical and microstructure characteristics of heat-treated of high-Cr WI and AISI4140 steel bimetal beams. J. Mater. Res. Technol. 11, 180 (2021). https://doi.org/10.1016/j.jmrt.2021.01.019

R. Zhou, Y. Jiang, D. Lu et al., The effect of volume fraction of WC particles on erosion resistance of WC reinforced iron matrix surface composites. Wear 255(1), 134–138 (2003). https://doi.org/10.1016/S0043-1648(03)00290-4

Z. Li, Y. Jiang, R. Zhou et al., Dry three-body abrasive wear behavior of WC reinforced iron matrix surface composites produced by V-EPC infiltration casting process. Wear 262(5), 649–654 (2007). https://doi.org/10.1016/j.wear.2006.07.009

Y. Jian, Z. Huang, J. Xing, J. Li, Effects of chromium additions on the three-body abrasive wear behavior of Fe-3.0 wt% B alloy. Wear 378–379, 165–173 (2017). https://doi.org/10.1016/j.wear.2017.02.042

Z. Zhou, Q. Shan, Y. Jiang et al., Effect of nanoscale V2C precipitates on the three-body abrasive wear behavior of high-Mn austenitic steel. Wear 436–437, 203009 (2019). https://doi.org/10.1016/j.wear.2019.203009

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant number 52265022) and Yunnan Fundamental Research Projects (Grant no. 202001AU070084).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sui, Y., Jin, H., Liu, Z. et al. Effects of Macrostructural Parameters on Microstructure and Properties of ZTAP/HCCI Honeycomb Composites. Inter Metalcast 18, 987–996 (2024). https://doi.org/10.1007/s40962-023-01062-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-023-01062-1