Abstract

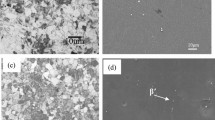

The effect of different heat treatment conditions on high cycle fatigue properties of newly developed Mg–4Y–3Nd–1.5Al alloy was studied. The results show that the minimum fatigue strength of the as-cast alloys is 66 MPa. The fatigue strength of the alloys after solution treatment (525 °C × 6 h + 550 °C × 12 h) is 77 MPa, and the fatigue strength is increased by about 17%. After peak aging treatment (525 °C × 6 h + 550 °C × 12 h + 200 °C × 20 h), the fatigue strength of alloys is increased to 95 MPa, which improves approximately 43% on the basement of the as-cast alloys 66 MPa. The fatigue performance of the alloys is closely correlated with the microstructure of the alloys. There are plenty of thick reticular Mg5RE eutectic phases at the grain boundary of the as-cast alloys. With the lowest fatigue strength, cracks can easily form at the eutectic phases. After solution treatment, the reticular phase of the alloy dissolves, the plasticity and deformability of the alloy are enhanced, the process of crack initiation is delayed, and the fatigue strength of the alloy is improved. Abundant nanoscale β″ phases precipitate in the matrix of the aged alloy, improving the strength of the matrix, giving the ability to hinder the deformation of the matrix, delaying crack formation delayed, and greatly improving the fatigue performance.

Similar content being viewed by others

References

J.H. Zhang, S.J. Liu, R.Z. Wu, L.G. Hou, M.L. Zhang, Recent developments in high-strength Mg-RE-based alloys: focusing on Mg–Gd and Mg–Y systems. J. Magnes. Alloy 6(3), 15 (2018)

J. Bian, B. Yu, L. Jiang et al., Research on the effect of Sr and Zr on microstructure and properties of Mg–4Zn alloy. Int. J. Metalcast. 15, 1483–1498 (2021)

C.P. Tang, W.H. Liu, Y.Q. Chen, X. Liu, Y.L. Deng, Effects of Y content on microstructures and mechanical properties of Mg–Gd–Y–Nd–Zr casting alloy. Int. Mater. Rev. 5, 75 (2016)

T.L. Zhu, C.L. Cui, T.L. Zhang, R.Z. Wu, S. Betsofen, Z. Leng, J.H. Zhang, M.L. Zhang, Influence of the combined addition of Y and Nd on the microstructure and mechanical properties of Mg–Li alloy. Mater. Design 57, 245–249 (2014)

T.L. Zhu, J.F. Sun, C.L. Cui, R.Z. Wu, S. Betsofen, Z. Leng, J.H. Zhang, M.L. Zhang, Influence of Y and Nd on microstructure, texture and anisotropy of Mg–5Li–1Al alloy. Mat. Sci. Eng. A600, 1–7 (2014)

J.X. Zheng, Z. Li, L.D. Tan, X.S. Xu, R.C. Luo, B. Chen, Precipitation in Mg–Gd–Y–Zr Alloy: atomic-scale insights into structures and transformations. Mater. Charact. 117, 76–83 (2016)

R.S. Chen, Y.H. Kang, H. Yan, Effects of heat treatment on the precipitates and mechanical properties of sand-cast Mg–4Y–2.3Nd–1Gd–0.6Zr magnesium alloy. Mat. Sci. Eng. A 645, 361–368 (2015)

B.P. Lyon, I. Syed, S. Heaney, Elektron 21-an aerospace magnesium alloy for sand cast and investment cast applications. Adv. Eng. Mater. 9(9), 793–798 (2007)

I. Naoko, K. Naoya, M. Toshiji, Effect of grain refinement on fatigue properties of Mg-0.3 at% Ca alloy in air and simulated body fluid. Mater. Trans. 63(1), 69–72 (2022)

H. Fu, S.Q. Yuan, K.C. Chan, X.S. Yang, Superior strength-ductility synergy and fatigue resistance of heterogeneous structured AZ41 Mg alloy by laser surface processing. Mat. Sci. Eng. A858, 144151 (2022)

M. Sun, D.P. Yang, Y. Zhang, L. Mao, X.K. Li, S. Pang, Recent advances in the grain refinement effects of Zr on Mg alloys: a review. Metals 12, 1388 (2022)

Z.M. Li, Q.G. Wang, A.A. Luo, P.H. Fu, L.M. Peng, Y.X. Wang, G.H. Wu, High cycle fatigue of cast Mg-3Nd-0.2Zn magnesium alloys. Metal. Mater. Trans. A 44(11), 5202–5215 (2013)

H.Z. Liang, X.P. Liang, F. Lv, Z.Y. Xiao, F.J. Sang, P.W. Li, Low-cycle fatigue behavior of a cast Mg–Y–Nd–Zr alloy by T6 heat treatment. Mat. Sci. Eng. A 676, 377–384 (2016)

Q. Ma, Z.C.G. Hildebrand, D.H. StJohn, The loss of dissolved zirconium in zirconium-refined magnesium alloys after remelting. Metal. Mater. Trans. A 40(10), 2470–2479 (2009)

D. Qiu, M.A. Zhang, J.A. Taylor, P.M. Kelly, A new approach to designing a grain refiner for Mg casting alloys and its use in Mg–Y-based alloys. Acta Mater. 57(10), 3052–3059 (2009)

J.C. Dai, M. Easton, S.M. Zhu, G.H. Wu, W.J. Ding, Grain refinement of Mg–10Gd alloy by Al additions. J. Mater. Res. 27(21), 2790–2797 (2012)

L. Wang, E.J. Guo, W.Y. Jiang, Y.C. Feng, S.C. Zhao, Y.K. Fu, H.T. Chen, Effect of Al addition on microstructure and mechanical properties of as-cast Mg–4Y–3Nd alloy. Philos. Mag. 100(2), 234–247 (2020)

Y.C. Feng, L. Wang, Y.K. Fu, S.C. Zhao, L.P. Wang, E.J. Guo, Effect of heat treatment on microstructure and mechanical properties of Mg-4Y-3Nd-1.5Al alloy. Rare. Metal. Mat. Eng. 50(5), 1826–1832 (2021)

D. Qiu, M.A. Zhang, J.A. Taylor, P.M. Kelly, A new approach to designing a grain refiner for Mg casting alloys and its use in Mg–Y-based alloys. Acta. Mater. 57(10), 3052–3059 (2009)

D.S. Wang, D.J. Li, Y.C. Xie, X.Q. Zeng, HRTEM studies of aging precipitate phases in the Mg-10Gd-3Y-0.4Zr alloy. J. Rare. Earths. 34(4), 441–446 (2016)

P. Zhang, Z.M. Li, H.Y. Yue, Strain-controlled cyclic deformation behavior of cast Mg–2.99Nd–0.18Zn–0.38Zr and AZ91D magnesium alloys. J. Mat. Sci. 51(11), 5469–5486 (2016)

C.H. Caceres, W.J. Poole, A.L. Bowles, C.J. Davidson, Section thickness, macrohardness and yield strength in high-pressure die cast magnesium alloy AZ91. Mat. Sci. Eng. A 402(2), 269–277 (2005)

Acknowledgements

The authors gratefully acknowledge the financial support from the National Natural Science Foundation of China (51804090, 51971086), Heilongjiang Provincial Key Research and Development Program (GZ20210080), the University Nursing Program for Young Scholars with Creative Talents in Heilongjiang Province (UNPYSCT-2020184).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yi, F., Wang, L., Feng, Y. et al. Effect of Heat Treatment on High Cycle Fatigue Properties of Mg–4Y–3Nd–1.5Al Alloy. Inter Metalcast 17, 2772–2779 (2023). https://doi.org/10.1007/s40962-022-00948-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-022-00948-w