Abstract

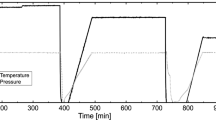

Turbine blades (rotary parts) and vanes (stationary components) are made from nickel-based superalloys. The replacement of high-cost aviation/industrial blades and vanes is the most important task in the turbojet engine repair industry. These parts which are manufactured by the investment casting process withstand high temperatures and high stresses/strains during the service. Depending on the temperature and strain rate, creep failure occurs by various mechanisms in superalloys. Cavitation is one of the modes of creep failure. In order to facilitate creep life extension of hot section parts and reduce overhaul of engine costs, alloy rejuvenation procedures have been investigated and implemented over the past few years. This study introduces a method including hot isostatic pressing (HIPing) and a post-HIP heat treatment for recovering the creep strength of the cast polycrystalline nickel-based superalloy Rene®80. To certify the positive effect of introduced method on the renovation of creep properties, the creep rupture tests at 850±1 °C/360±2 MPa were assessed. As revealed by the results of this evaluation, the creep properties of Rene®80 can be recovered by HIP procedure (1205 °C /150MPa /4 h) in combination with a post-HIP heat treatment (1093 °C /4hr + 1054 °C /4hr + 845 °C /24hr).

Similar content being viewed by others

References

J. Błachnio, J. Spychała, D. Zasada, Analysis of structural changes in a gas turbine blade as a result of high temperature and stress. Eng. Fail. Anal. 127, 105554 (2021). https://doi.org/10.1016/j.engfailanal.2021.105554

H. Kuhn (volume coordinator), Mechanical Testing and Evaluation, Volume 8, ASM handbook, 2000

B. Swain, P. Mallick, S. Patel, R. Roshan, S.S. Mohapatra, S. Bhuyan, M. Priyadarshini, B. Behera, S. Samal, A. Behera, Failure analysis and materials development of gas turbine blades. Mater. Today Proc. 33, 5143 (2020). https://doi.org/10.1016/j.matpr.2020.02.859

P. Puspitasari, A. Andoko, P. Kurniawan, Failure analysis of a gas turbine blade: a review. IOP Conf. Series: Mater. Sci. Eng. 1034, 012156 (2021). https://doi.org/10.1088/1757-899X/1034/1/012156

W. T. Becker, R. J. Shipley (volume coordinators), Failure Analysis and Prevention, Volume 11, ASM handbook, 2002

B. Ruttert, D. Bürger, L. Mujica Roncery, A. Basir Parsa, P. Wollgramm, G. Eggeler, W. Theisen, Rejuvenation of creep resistance of a Ni-base single-crystal superalloy by hot isostatic pressing. Mater. Design. 134, 418–425 (2017). https://doi.org/10.1016/j.matdes.2017.08.059

H. Zhang, A. Wang, Z. Wen, Z. Yue, C. Zhang, Effects of hot isostatic pressing (HIP) on microstructure and mechanical properties of K403 nickel-based superalloy. High Temp. Mater. Process. 35(5), 463–471 (2015). https://doi.org/10.1515/htmp-2014-0210

B. Ruttert, I.L. Galilea, L.M. Roncery, W. Theisen, Microstructural design of Ni-base superalloys by hot isostatic pressing. Mater. Res. Proc. 10, 107–113 (2019). https://doi.org/10.21741/9781644900031-15

Y.L. Kuo, T. Nagahari, K. Kakehi, The effect of post-processes on the microstructure and creep properties of alloy718 built up by selective laser melting. Materials 11, 1–13 (2018). https://doi.org/10.3390/ma11060996

A.I. Epishin, T. Link, B. Fedelich, I.L. Svetlov, E.R. Golubovskiy, Hot isostatic pressing of single-crystal nickel-base superalloys: mechanism of pore closure and effect on mechanical properties. MATEC Web Conf. 14, 08003 (2014). https://doi.org/10.1051/matecconf/20141408003

J. Wang, Z. Jiang, Application research progress of hot isostatic pressing technology in nickel-based single crystal superalloy, E3S Web of Conferences 155, 01012 (2020). Doi: https://doi.org/10.1051/e3sconf/202015501012

C.L. Qiu, M.M. Attallah, X.H. Wu, P. Andrews, Influence of hot isostatic pressing temperature on microstructure and tensile properties of a nickel-based superalloy powder. Mater. Sci. Eng. A. 564, 176–185 (2013). https://doi.org/10.1016/j.msea.2012.11.084

S. Yang, J. Yun, C.S. Seok, Rejuvenation of IN738LC gas-turbine blades using hot isostatic pressing and a series of heat treatments. J. Mech. Sci. Technol. 34(11), 4605–4611 (2020). https://doi.org/10.1007/s12206-020-1018-2

K.J. Tan, X.G. Wang, J.J. Liang, J. Meng, Y.Z. Zhou, X.F. Sun, Effects of rejuvenation heat treatment on microstructure and creep property of a Ni-based single crystal superalloy. J. Mater. Sci. Technol. 60, 206–215 (2021). https://doi.org/10.1016/j.jmst.2020.05.032

R. Acharya, R. Bansal, J.J. Gambone, M.A. Kaplan, G.E. Fuchs, N.G. Rudawski, S. Das, Additive manufacturing and characterization of rene 80 superalloy processed through scanning laser epitaxy for turbine engine hot-section component repair. Adv. Eng. Mater. 17, 942–950 (2015). https://doi.org/10.1002/adem.201400589

R. C. Reed, The superalloys fundementals and applications, Cambridge University Press, 2006, pp. 51-53

J. Safari, S. Nategh, On the heat treatment of Rene-80 nickel-base superalloy. J. Mater. Proc. Tech. 176, 240–250 (2006). https://doi.org/10.1016/j.jmatprotec.2006.03.165

M.M. Barjesteh, S.M. Abbasi, K. Zangeneh-Madar, K. Shirvani, The effect of heat treatment on characteristics of the gamma prime phase and hardness of the nickel-based superalloy Rene80. Mater. Chem. Phys. 227, 46–55 (2019). https://doi.org/10.1016/j.matchemphys.2019.01.038

C. Yang, Y. Xu, H. Nie, X. Xiao, G. Jia, Z. Shen, Effects of heat treatments on the microstructure and mechanical properties of Rene80. Mater. Design. 43, 66–73 (2013). https://doi.org/10.1016/j.matdes.2012.06.039

D. A. DeAntonio, D. Duhl, T. Howson, M. F. Rothman, Heat Treating of Superalloys, Heat Treating, Volume 4, ASM handbook, 1991

M.F. Moreira, L.B. Fantin, F.B. Neto, C.R.F. Azevedo, Microstructural and mechanical characterization of as-cast nickel-based superalloy (IN-713C). Int. J. Met. (2020). https://doi.org/10.1007/s40962-020-00540-0

S. Utada, Effect of a prior plastic deformation during heat treatments on the mechanical properties of Ni-based superalloys for turbine blade application, Ph.D thesis, 2020. National Higher School of Mechanics and Aerotechnics, University of Poitiers, France

M.M. Barjesteh, S.M. Abbasi, K. Zangeneh-Madar, K. Shirvani, Creep rupture properties of bare and coated polycrystalline nickel-based superalloy Rene®80. J. Min. Metall. Sect. B-Metall. 57(3), 401–412 (2021). https://doi.org/10.2298/JMMB201203036B

C. Parlikar, D.V.V. Satyanarayana, D. Chatterjee, N. Hazari, D.K. Das, Effect of Pt–aluminide bond coat on tensile and creep behavior of a nickel-base single crystal superalloy. Mater. Sci. Eng. A. 639, 575–584 (2015). https://doi.org/10.1016/j.msea.2015.05.051

M.T. Kim, D.S. Kim, O.Y. Oh, Effect of γ’ precipitation during hot isostatic pressing on the mechanical property of a nickel-based superalloy. Mater. Sci. Eng. A. 480, 218–225 (2008). https://doi.org/10.1016/j.msea.2007.07.020

Y. Du, Z. Tan, Y. Yang, X. Wang, Y. Zhou, J. Li, X. Sun, Creep properties of a nickel-based single crystal superalloy with low density. Met. Mater. Int. 4, 1–6 (2021). https://doi.org/10.1007/s12540-020-00903-6

L. Wang, Y. Liu, J. Liang, Effect of rejuvenation heat treatment on the creep property and microstructural evolution of a Ni-base superalloy. Appl. Sci. 10, 1187–1200 (2020). https://doi.org/10.3390/app10031187

Y. Zhou, S. Rao, Z. Zhang, Z. Zhao, Interaction of hot isostatic pressing temperature and hydrostatic pressure on the healing of creep cavities in a nickel-based superalloy. Mater. Design. 49, 25–27 (2013). https://doi.org/10.1016/j.matdes.2013.01.055

A. Baldan, Rejuvenation procedures to recover creep properties of nickel-base superalloys by heat treatment and hot isostatic pressing techniques. J. Mater. Sci. 26, 3409–3421 (1991). https://doi.org/10.1007/BF00557126

O.M. Horst, B. Ruttert, D. Burger, L. Heep, H. Wang, A. Dlouhy, W. Theisen, G. Eggeler, On the rejuvenation of crept Ni-Base single crystal superalloys (SX) by hot isostatic pressing (HIP). Mater. Sci. Eng. A. 758, 202–214 (2019). https://doi.org/10.1016/j.msea.2019.04.078

M.R.G. Prasad, S. Gao, N. Vajragupta, A. Hartmaier, Influence of trapped gas on pore healing under hot isostatic pressing in nickel-base superalloys. Curr. Comput.-Aided Drug Des. 10, 1147–1162 (2020). https://doi.org/10.3390/cryst10121147

X.G. Zheng, Y.-N. Shi, L.H. Lou, Healing process of casting pores in a Ni-based superalloy by hot isostatic pressing. J. Mater. Sci. Technol. 31(11), 1151–1157 (2015). https://doi.org/10.1016/j.jmst.2015.07.004

X. Wang, Y. Zhou, J. Dong, T. Wang, Z. Zhao, Z. Zhang, Microstructural changes of a creep damaged nickel-based K002 superalloy containing Hf element under different HIP temperatures. High Temp. Mater. Proc. 35(2), 153–159 (2016). https://doi.org/10.1515/htmp-2014-0128

T. Pollock, S. Tin, J. Propul, Nickel-based superalloys for advanced turbine engines: chemistry, microstructure and properties. Power 22, 361–374 (2006). https://doi.org/10.2514/1.18239

W. Xuan, X. Zhang, Y. Zhao, J. Li, B. Wang, X. Ren, Z. Ren, Mechanism of improved intermediate temperature plasticity of nickel-base single crystal superalloy with hot isostatic pressing. J. Mater. Res. Technol. 14, 1609–1617 (2021). https://doi.org/10.1016/j.jmrt.2021.07.010

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Barjesteh, M.M. Rejuvenation of Nickel-Based Superalloy Experiencing Creep via Use of Hot Isostatic Pressing and Heat Treatment. Inter Metalcast 16, 1960–1975 (2022). https://doi.org/10.1007/s40962-021-00739-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-021-00739-9