Abstract

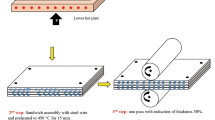

In situ precipitation of primary Si (SiP) particles within the microstructure of Si-containing Zn–22Al alloys, also known as ZA22/SiP composites, can improve their hardness and mechanical strength, provided that the size, morphology, and distribution of SiP particles are optimized. In this study, Ti–B treatment was employed to modify the microstructure and improve the mechanical properties of ZA22–xSi (x = 4 and 8 wt%) composite. According to the results, Ti–B treatment eliminated the primary α-Al dendrites, reduced the volume fraction of remaining α-Al phase within the microstructure, reduced the size of SiP particles, and improved their distribution within the matrix. Moreover, the size of SiP particles is reduced from 25.2 ± 9.5 to 30.1 ± 4.4 μm in non-modified samples containing 4 and 8 wt% Si to 14.7 ± 6.3 and 19.6 ± 5.3 μm in the samples modified by Ti–B, respectively. Ti–B addition also substantially refined and homogenized the distribution of the other second phases and porosities. The mechanical properties analyses revealed that, at a given Si concentration, the hardness of the alloys modified by Ti–B was relatively less than that of the non-modified ones. Moreover, the tensile strength and fracture strain of modified ZA22–4Si and ZA22–8Si composites are increased by about 15 and 59, and 60 and 82%, respectively.

Similar content being viewed by others

References

W.K. Krajewski, A.L. Greer, G. Piwowarski, P.K. Krajewski, Property enhancement by grain refinement of zinc–aluminium foundry alloys. IOP Conf. Ser. Mater. Sci. Eng. 117, 012004 (2016)

M.A.M. Arif, M.Z. Omar, N. Muhamad, J. Syarif, P. Kapranos, J. Mater. Sci. Technol. 29(8), 765 (2013)

Y. Zhang, X. Zeng, L. Yang, K. Sun, Z. Song, Philos. Mag. Lett. 93(6), 322 (2013)

B.K. Prasad, Mater. Trans., JIM 38(8), 701 (1997)

B.K. Prasad, Mater. Sci. Technol. 19(3), 327 (2003)

G. Purcek, B.S. Altan, I. Miskioglu, A. Patil, Mater. Sci. Technol. 21(9), 1044 (2005)

G. Purcek, O. Saray, T. Kucukomeroglu, M. Haouaoui, I. Karman, Mater. Sci. Eng. 527A(15), 3480 (2010)

V. Spuskanyuk, A. Berezina, V. Dubodelov, O. Davydenko, V. Fikssen, K. Sliva, T. Monastyrska, Mater. Sci. Metall. Eng. 2(3), 35 (2019)

W. Jianhua, W. Xiande, T. Hao, S. Xuping, China Found. 8(4), 397 (2011)

R. Michalik, Arch. Metall. Mater. 58(1), 49 (2013)

T. Savaşkan, A.P. Hekimoğlu, G. Pürçek, Tribol. Int. 37(1), 45 (2004)

S.D. Pritha Choudhury, B.K. Datta, J. Mater. Sci. Technol. 37(10), 2103 (2002)

T. Savaşkan, G. Pürçek, A. Hekimoğlu, Tribol. Lett. 15(3), 257 (2003)

W. Krajewski, Physica Status Solidi 147(2), 389 (1995)

S.J.E.H. Morgan, Zinc and Its Alloys and Compounds (Halsted Press West Sussex, London, 1985)

T. Savaşkan, A. Aydıner, Wear 257(3), 377 (2004)

T. Savaşkan, O. Bican, Mater. Sci. Eng. 404A(1), 259 (2005)

K. Berent, J. Pstruś, T. Gancarz, J. Mater. Eng. Perf. 25, 3375 (2016)

N. Tenekedjiev, J.E. Gruzleski, Cast Metals 3(2), 96 (1990)

T.J. Chen, C.R. Yuan, M.F. Fu, Y. Ma, Y.D. Li, Y. Hao, Mater. Sci. Technol. 24(11), 1321 (2008)

T.J. Chen, C. Yuan, M. Fu, Y. Ma, Y.D. Li, Y. Hao, China Found. 6(1), 1 (2009)

Z. Shi, M. Gu, R. Wu, J. Liu, J. Mater. Proc. Technol. 63(1), 417 (1997)

C.L. Xu, Q.C. Jiang, Mat. Sci. Eng. 437(2), 451 (2006)

Y. Liu. J. Yin, H. Li, Y. Zhong, Effect of Extrusion Ratio on Mechanical Properties of Al–20Si Produced by Spray Deposition and Continuous Extrusion Technique. Light Metals 2016 (The Mineral, Metals & Materials Society, Switzerland, 2016)

X.A. Song, Adv. Mater. Res. 328–330, 1487 (2011)

W.A. Pollard, K.M. Pickwick, J.T. Jubb, R.H. Packwood, Can. Metall. Quart. 13(4), 535 (1974)

A.F. Skenazi, J.P.D. Coutsouradis, B. Magnus, M. Meeus, Metall 37(9), 898 (1983)

J. Xu, M. Shirooyeh, J. Wongsa-Ngam, D. Shan, B. Guo, T.G. Langdon, Mater. Sci. Eng. 586A, 108 (2013)

R. Taghiabadi, A. Fayegh, A. Pakbin, M. Nazari, M.H. Ghoncheh, Trans. Nonferrous Met. Soc. China 28(7), 1275 (2018)

R.P. Taylor, S.T. McClain, J.T. Berry, Int. J. Cast Met. Res. 11(4), 247 (1999)

M.M. Lachowicz, M.B. Lachowicz, Arch. Found. Eng. 17(3), 79 (2017)

M. Agapie, B. Varga, Analysis of phase transformations in eutectoid Zn–Al alloys. in 5th international conference on Advanced Composite Materials Engineering, Brasov, Romani (2014)

W. Ding, T. Xia, W. Zhao, Materials 7(5), 3663 (2014)

X. Zhu, W. Jiang, M. Li, H. Qiao, Y. Wu, J. Qin, X. Liu, Metals 5(1), 40 (2015)

F. Wang, D. Eskin, J. Mi, T. Cannolley, J. Lindsay, M. Mounib, Acta Mater. 116, 354 (2016)

K.T. Kashyap, T. Chndrashekar, Bull. Mater. Sci. 24, 345 (2001)

W. Ding, T. Xia, W. Zhao, Y. Xu, Mater (Basel) 7(2), 1188 (2014)

M. Gupta, S. Ling, J. Alloys Compd. 287(1), 284 (1999)

D. Lu, Y. Jiang, G. Guan, R. Zhou, Z. Li, R. Zhou, J. Mater. Proc. Technol. 189(1), 13 (2007)

M. Rahimian, N. Parvin, N. Ehsani, Mater. Sci. Eng. 527(4), 1031 (2010)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yousefi, D., Taghiabadi, R., Shaeri, M.H. et al. Enhancing the Mechanical Properties of Si Particle Reinforced ZA22 Composite by Ti–B Modification. Inter Metalcast 15, 206–215 (2021). https://doi.org/10.1007/s40962-020-00447-w

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-020-00447-w