Abstract

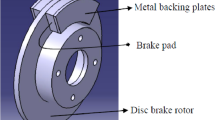

The brake noise is one of the highest incidences of complaints from OEM’s customers, causing problems such as passenger disappointment and warranty costs. With the improvement of the comfort and soundproofing of the automobile, the brake noise has increased customers’ concerns, making them believe that it is a component defect, although it is fulfilling its functions. One of the factors that can attenuate the vibration in a structure is the increase in its inherent damping capacity. Therefore, a material capable of dissipating energy of vibrations may minimize noise, vibration and harshness problems in the braking system. In this work, an experimental study of mechanical properties, microstructural analysis and damping capacity was carried out on different nodular cast irons with variation of the Co, Si, RE contents. The research goal is the achievement of the best compromise between the mechanical properties required for the braking system parts and their damping capacity. In spite of the damping capacity and tensile strength that were likely to be mutually exclusive, a simultaneous increase in both was registered for samples with high Si content, comprising different additions of RE, and for samples alloyed with Co. These results seem to be associated with solid solution strengthening of a fully ferritic matrix, combined with nodule density increase.

Similar content being viewed by others

References

R.J. Canali, Determinação de propriedades físicas de diferentes materiais para discos e pastilhas de freio e relação destas propriedades com ruído. Master thesis, Universidade Federal do Rio Grande do Sul, Escola de Engenharia, (2002)

N.M. Kinkaid, O.M. O’Reilly, P. Papadopoulos, Automotive disc brake squeal. J. Sound Vib. 267(1), 105–166 (2003)

M.A. Panza, A review of experimental techniques for NVH analysis on a commercial vehicle. Energy Procedia 82, 1017–1023 (2015)

T. Bein, J. Bös, D. Mayer, T. Melz, Advanced materials and technologies for reducing noise, vibration and harshness (NVH) in automobiles, in Advanced Materials in Automotive Engineering, ed. by J. Rowe (Woodhead Publishing, Cambridge, 2012), pp. 254–298

D. Mayer, J. Militzer, T. Bein, Integrated solutions for noise and vibration control in vehicles. SAE Int. J. Passeng. Cars Mech. Syst. 7(2014-01-2048), 1183–1193 (2014)

C. Beards, Structural Vibration: Analysis and Damping (Elsevier, Amsterdam, 1996)

M.N. Mazlee, J.B. Shamsul, K. Hussin, S.S. Rizam, K.R. Ahmad, M.W.M. Fitri, M.Z. Ruhiyuddin, M.F. Abdullah, Damping behaviour of as-received and as-cast Al–Si–Mg alloys. Paper presented at National Metallurgical Conference, Malaysia (2007)

H.T. Angus, Cast iron: Physical and Engineering Properties, 2nd edn. (Butterworths, New York, 1976)

S.S. Rao, Mechanical Vibrations (Pearson Prentice Hall, Upper Saddle River, 2005)

G.H. Wu, Z.Y. Dou, L.T. Jiang, J.H. Cao, Damping properties of aluminum matrix-fly ash composites. Mater. Lett. 60(24), 2945–2948 (2006). Cited in: C.Y. Kang, J.H. Sung, G.H. Kim, B.S. Kim, I.S. Kim, Effect of heat treatment on the damping capacity of austempered ductile cast iron. Mater. Trans. 50(6), 1390–1395 (2009)

J. Åberg, On the experimental determination of damping of metals and calculation of thermal stresses in solidifying shells. Doctoral thesis, Department of Materials Science, Royal Institute of Technology, KTH (2006)

Z. Zhang, R.J. Perez, E.J. Lavernia, Documentation of damping capacity of metallic ceramic and metal-matrix composite materials. J. Mater. Sci. 28, 2395–2404 (1993)

E. Plénard, In Recent Research on Cast Iron, vol. 707 (Gordon and Breach, New York, 1964). Cited in: J.M. Song, S.C. Lin, T.S. Lui, L.H. Chen, Y.H. Song, Effects of matrix structure on the resonant vibration behavior of spheroidal graphite cast iron. Mater. Trans. 45(4), 1379–1382 (2004)

A. Granato, K. Lucke, Theory of mechanical damping due to dislocations. J. Appl. Phys. 27, 583–593 (1956). Cited in: J.M. Song, S.C. Lin, T.S. Lui, L.H. Chen, Y.H. Song, Effects of matrix structure on the resonant vibration behavior of spheroidal graphite cast iron. Mater. Trans. 45(4), 1379–1382 (2004)

I. Minkoff, The Physical Metallurgy of Cast Iron, vol. 292 (Wiley, New York, 1983). Cited in: J.M. Song, S.C. Lin, T.S. Lui, L.H. Chen, Y.H. Song, Effects of matrix structure on the resonant vibration behaviour of spheroidal graphite cast iron. Mater. Trans. 45(4), 1379–1382 (2004)

A.N. Damir, A. Elkhatib, G. Nassef, Prediction of fatigue life using modal analysis for grey and ductile cast iron. Int. J. Fatigue 29, 499–507 (2007)

S.H. Carpenter, T.E. Stuch, R. Salzbrenner, An investigation of the mechanical damping of ductile iron. Metall. Mater. Trans. A 26(11), 2785–2790 (1995)

S.C. Lin, T.S. Lui, L.H. Chen, Effect of microstructure on resonant vibration fatigue fracture of ferritic spheroidal graphite cast iron. Int. J. Cast Met. Res. 13, 77–83 (2000). Cited in: S.C. Lin, T.S. Lui, L.H. Chen, J.M. Song, Effect of pearlite on the vibration-fracture behavior of spheroidal graphite cast irons under resonant conditions. Metall. Mater. Trans. A 33A (2002)

S.C. Lin, T.S. Lui, L.H. Chen, Effect of nodularity on resonant vibration fracture behavior in upper bainitic and ferritic cast irons. Metall. Mater. Trans. A 31(9), 2193–2203 (2000). Cited in: S.C. Lin, T.S. Lui, L.H. Chen, J.M. Song, Effect of pearlite on the vibration-fracture behavior of spheroidal graphite cast irons under resonant conditions. Metall. Mater. Trans. A 33A (2002)

S.C. Lin, T.S. Lui, L.H. Chen, J.M. Song, Effect of pearlite on the vibration-fracture behavior of spheroidal graphite cast irons under resonant conditions. Metall. Mater. Trans. A 33A, 2623–2634 (2002)

C.H. Hsu, M.L. Chen, C.J. Hu, Microstructure and mechanical properties of 4% cobalt and nickel alloyed ductile irons. Mater. Sci. Eng. A 444, 339–346 (2007)

J.O. Choi, J.Y. Kim, C.O. Choi, J.K. Kim, P.K. Rohatgi, Effect of rare earth element on microstructure formation and mechanical properties of thin wall ductile iron castings. Mater. Sci. Eng. A 383, 323–333 (2004)

P. Weiß, J. Brachmann, A. Bührig-Polaczek, S.F. Fischer, Influence of nickel and cobalt on microstructure of silicon solution strengthened ductile iron. Mater. Sci. Technol. 31(12), 1479–1485 (2015)

M.M. Ibrahim, M.M. Mourad, A.A. Nofal, A.I. Farahat, Microstructure, hot oxidation resistance and damping capacity of Al-alloyed cast iron. Int. J. Cast Met. Res. 30(2), 61–69 (2017)

Acknowledgements

The authors gratefully acknowledge the support of the partners of the Brake Noise project, involving SAKTHI, Portugal, S.A., Fundación Azterlan, Centre for Innovation and Technology N. Mahalingam, Faculty of Engineering of the University of Porto and the University of Aveiro.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This paper is an invited submission to IJMC selected from presentations at the 2nd Carl Loper 2019 Cast Iron Symposium held September 30 to October 1, 2019, in Bilbao, Spain.

Rights and permissions

About this article

Cite this article

Pereira, I., Alonso, G., Anjos, V. et al. The Influence of Alloying Elements on Damping Capacity of Nodular Cast Irons for Braking System Components. Inter Metalcast 14, 802–808 (2020). https://doi.org/10.1007/s40962-020-00426-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-020-00426-1