Abstract

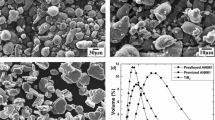

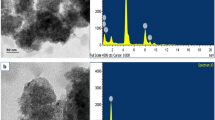

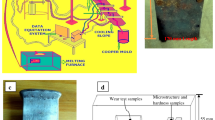

The present investigation focuses on improvement in mechanical properties of AlSi5Cu3 aluminum alloy by in situ synthesis of TiB2 reinforcement particles. Stochiometrically calculated amount of potassium tetrafluoro borate and potassium hexafluoro titanate were used for the development of 3 and 6 wt% particles of TiB2 in the liquid metal. The melt having TiB2 particles was allowed to solidify naturally in the sand mold. X-ray diffraction (XRD) and scanning electron microscopy (SEM) revealed the formation of hexagonal TiB2 particles within the matrix. Microstructural studies concluded the formation of micron size TiB2 particles and reduction in grain size. Ultimate tensile strength increased from 21 to 64% and hardness increased from 30 to 50% compared to AlSi5Cu3 alloy due to the formation of 3% and 6% TiB2 particles, respectively.

Similar content being viewed by others

References

North American Light Vehicle Aluminum Content Study. (Ducker Worldwide Study, 2016), http://www.ducker.com/news-insights/ducker-worldwide-studyaluminum-content-cars-public-summary. Accessed 31 Aug 2017

A.S.M. Handbook, Properties and selection: nonferrous alloys and special-purpose materials. ASM Int. 2, 597–599 (1990)

J.H. Sokolowski, M.B. Djurdjevic, C.A. Kierkus et al., J. Mater. Process. Technol. 109, 174 (2001). https://doi.org/10.1016/S0924-0136(00)00793-7

R. Mahmudi, P. Sepehrband, H.M. Ghasemi, Mater. Lett. 60, 2606 (2006). https://doi.org/10.1016/j.matlet.2006.01.046

S. Poria, P. Sahoo, G. Sutradhar, Silicon 8, 591 (2016). https://doi.org/10.1007/s12633-016-9437-5

S. Poria, G. Sutradhar, P. Sahoo, Mater. Res. Express 5, 056509 (2018). https://doi.org/10.1088/2053-1591/aac0df

Y. Pazhouhanfar, B. Eghbali, Mater. Sci. Eng. A 172, 180 (2018). https://doi.org/10.1016/j.msea.2017.10.087

S.C. Tjong, Z.Y. Ma, Mater. Sci. Eng. R 29, 49 (2000). https://doi.org/10.1016/S0927-796X(00)00024-3

S.M.Y. Kaku, A.K. Khanra, M.J. Davidson, J Alloys Compd 666, 675 (2018). https://doi.org/10.1016/j.jallcom.2018.03.088

R. Gecu, A. Karaaslan, Inter. Metalcast. 1, 9 (2018). https://doi.org/10.1007/s40962-018-0253-0

S. Soltani, R.A. Khosroshahi, R.T. Mousavian et al., Rare Met. 36, 581 (2017). https://doi.org/10.1007/s12598-015-0565-7

S. Agrawal, A.K. Ghose, I. Chakrabarty, Mater. Des. 113, 195 (2017)

J.M. Mistry, P.P. Gohil, Compos Part B Eng 190, 204 (2019). https://doi.org/10.1016/j.compositesb.2018.10.074

R. Mohammadi Badizi, M. Askari-Paykani, A. Parizad et al., Inter. Metalcast. 12, 565 (2018)

A.R. Kennedy, A.E. Karantzalis, S.M. Wyatt, J. Mater. Sci. 34, 933 (1999). https://doi.org/10.1023/A:1004519306186

M.K. Akbari, H.R. Baharvandi, K. Shirvanimoghaddam, Mater. Des. 66, 150 (2015). https://doi.org/10.1016/j.matdes.2014.10.048

A.M. Samuel, H.W. Doty, S. Valtierra et al., Inter. Metalcast. 11, 305 (2017). https://doi.org/10.1007/s40962-016-0075-x

B. Yang, Y.Q. Wang, B.L. Zhou, Metall. Mater. Trans. B 29, 635 (1998). https://doi.org/10.1007/s11663-998-0098-7

M. Emamy, M. Mahta, J. Rasizadeh, Compos. Sci. Technol. 66, 1063 (2006). https://doi.org/10.1016/j.compscitech.2005.04.016

B.S. Murty, S.A. Kori, M. Chakraborty, Int. Mater. Rev. 47, 3 (2002). https://doi.org/10.1179/095066001225001049

Y. Han, X. Liu, X. Bian, Compos. A 33, 439 (2002). https://doi.org/10.1016/S1359-835X(01)00124-5

J. Liu, Z. Liu, Z. Dong et al., J. Alloys Compd. 1008, 1017 (2018). https://doi.org/10.1016/j.jallcom.2018.06.303

A. Changizi, A. Kalkanli, N. Sevinc, J. Alloys Compd. 509, 237 (2011). https://doi.org/10.1016/j.jallcom.2010.08.089

P. Davies, J.L.F. Kellie, D.P. Patron, J.V. Wood, Metal Matrix Alloys. U.S. Patent 6,228,185, 2001

S. Kumar, V.S. Sarma, B.S. Murty, Mater. Sci. Eng. A 476, 333 (2008). https://doi.org/10.1016/j.msea.2007.04.113

L. Lü, M.O. Lai, Y. Su et al., Scripta Mater. 45, 1017 (2001). https://doi.org/10.1016/S1359-6462(01)01128-9

A.M. Davidson, D. Regener, Compos. Sci. Technol. 60, 865 (2000). https://doi.org/10.1016/S0266-3538(99)00151-7

S. Natarajan, R. Narayanasamy, S.K. Babu et al., Mater. Des. 30, 2521 (2009). https://doi.org/10.1016/j.matdes.2008.09.037

H.M. Rajan, S. Ramabalan, I. Dinaharan et al., Arch. Civil Mech. Eng. 14, 72 (2014). https://doi.org/10.1016/j.acme.2013.05.005

S. Kumar, M. Chakraborty, V.S. Sarma et al., Wear 265, 134 (2008). https://doi.org/10.1016/j.wear.2007.09.007

C.S. Ramesh, S. Pramod, R. Keshavamurthy, Mater. Sci. Eng. A 528, 4125 (2011). https://doi.org/10.1016/j.msea.2011.02.024

Z. Zhang, D.L. Chen, Mater. Sci. Eng. A 483, 148 (2008). https://doi.org/10.1016/j.msea.2006.10.184

Acknowledgement

The authors gratefully acknowledge the support from Department of Science and Technology (DST), New Delhi, sponsored SMART Foundry Project (DST/TSG/AMT/2015/332 dated 17/08/2016).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ayar, V.S., Sutaria, M.P. Development and Characterization of In Situ AlSi5Cu3/TiB2 Composites. Inter Metalcast 14, 59–68 (2020). https://doi.org/10.1007/s40962-019-00328-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-019-00328-x