Abstract

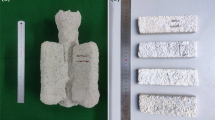

Under conditions of changing sand-mould strength and rod diameter, hot tearing susceptibility of Mg WE43A alloys was studied using constrained rod casting solidified in a sand mould. Variations of temperature and shrinkage force with time during solidification of Mg WE43A alloy were recorded by means of a thermocouple and a force sensor. Susceptibility to hot tearing at hot section was decreased with increasing rod diameter from 10 mm to 20 mm. The rod with 10 mm diameter fractured, and the rod with 15 mm diameter presented hot tearing. No hot tearing was noted for the rod with 20 mm diameter. For the resin content of 1%, 1.5%, 2%, 2.5% and 3%, the tensile strength of sand mould was measured as 0.12, 0.18, 0.28, 0.17 and 0.15 MPa, respectively. The casting fractured at hot spot position for the sand mould with strength of 0.12 MPa. Hot tearing occurred at hot spot for the sand mould with strength of 0.15 MPa. No hot tearing was found at hot spot for the sand mould with strength of 0.28 MPa. The present research confirms that increasing the sand-mould strength and avoiding the entrapment of sand particles and the formation of gas pores during casting increase the resistance to hot tearing.

Similar content being viewed by others

References

A.A. Luo, Magnesium: current and potential automotive applications. JOM 54(2), 42–48 (2002)

M. Paliwal, S.K. Das, J. Kim, I.H. Jung, Diffusion of Nd in hcp Mg and interdiffusion coefficients in Mg-Nd system. Scr. Mater. 108, 11–14 (2015)

V. Angelini, L. Ceschini, A. Morri, Influence of heat treatment on microstructure and mechanical properties of rare earth-rich magnesium alloy. Int. J. Metalcast. 11(3), 382–395 (2017)

I.H. Jung, M. Sanjari, J. Kim, S. Yue, Role of RE in the deformation and recrystallization of Mg alloy and a new alloy design concept for Mg-RE alloys. Scr. Mater. 102, 1–6 (2015)

P. Mengucci, G. Barucca, G. Riontino, D. Lussana, M. Massazza, R. Ferragut, E.H. Aly, Structure evolution of a WE43 Mg alloy submitted to different thermal treatments. Mater. Sci. Eng. A 479(1-2), 37–44 (2008)

L. Gao, R.S. Chen, E.H. Han, Enhancement of ductility in high strength Mg-Gd-Y-Zr alloy. Trans. Nonferr. Metal. Soc. 21(4), 863–868 (2011)

S.M. He, X.Q. Zeng, L.M. Peng, X. Gao, J.F. Nie, W.J. Ding, Microstructure and strengthening mechanism of high strength Mg-10Gd-2Y-0.5Zr alloy. J. Alloys Compd. 427(1–2), 316–323 (2007)

L. Bichler, C. Ravindran, New developments in assessing hot tearing in magnesium alloy castings. Mater. Des. 31(Suppl. 1), S17–S23 (2010)

M.A. Easton, M.A. Gibson, S. Zhu, T.B. Abbott, An a priori hot-tearing indicator applied to die-cast magnesium-rare earth alloys. Metall. Mater. Trans. A 45(8), 3586–3595 (2014)

J. Song, F. Pan, B. Jiang, A. Atrens, M.X. Zhang, Y. Lu, A review on hot tearing of magnesium alloys. J. Magn. Alloy 4(3), 151–172 (2016)

Z. Liu, S.B. Zhang, P.L. Mao, F. Wang, Effects of Y on hot tearing susceptibility of Mg-Zn-Y-Zr alloys. Trans. Nonferr. Metal. Soc. 24(4), 907–914 (2014)

Z. Wang, Y. Huang, A. Srinivasan, Z. Liu, F. Beckmann, K.U. Kaine, N. Hort, Hot tearing susceptibility of binary Mg–Y alloy castings. Mater. Des. 47(9), 90–100 (2013)

H. Huang, P.H. Fu, Y.X. Wang, L.M. Peng, H.Y. Jiang, Effect of pouring and mold temperatures on hot tearing susceptibility of AZ91D and Mg-3Nd-0.2Zn-Zr Mg alloys. Trans. Nonferr. Metal. Soc. 24(4), 922–929 (2014)

L. Bichler, A. Elsayed, K. Lee, C. Ravindran, Influence of mold and pouring temperatures on hot tearing susceptibility of AZ91D magnesium alloy. Int. J. Metalcast. 2(1), 43–54 (2008)

M. Pokorny, C. Monroe, C. Beckermann, Prediction of hot tear formation in a magnesium alloy permanent mold casting. Int. J. Metalcast. 2(4), 41–53 (2008)

A. Srinivasan, Z. Wang, Y. Huang, F. Beckmann, K.U. Kainer, N. Hort, Hot tearing characteristics of binary Mg–Gd alloy castings. Metall. Mater. Trans. A 44(5), 2285–2298 (2013)

P. Gunde, A. Schiffl, P.J. Uggowitzer, Influence of yttrium additions on the hot tearing susceptibility of magnesium–zinc alloys. Mater. Sci. Eng. A 527(26), 7074–7079 (2010)

S.S. Li, B. Tang, X.Y. Jin, D.B. Zeng, An investigation on hot-cracking mechanism of Sr addition into Mg–6Al–0.5Mn alloy. J. Mater. Sci. 47(4), 2000–2004 (2011)

J. Song, Z. Wang, Y. Huang, A. Srinivasan, F. Beckmann, K.U. Kainer, N. Hort, Hot tearing characteristics of Mg–2Ca–xZn alloys. J. Mater. Sci. 51(5), 2687–2704 (2016)

S. Suyitno, D.G. Eskin, V.I. Savran, L. Katgerman, Effects of alloy composition and casting speed on structure formation and hot tearing during direct-chill casting of Al–Cu alloys. Metall. Mater. Trans. A 35(11), 3551–3561 (2004)

L. Sweet, M.A. Easton, J.A. Taylor, J.F. Grandfield, C.J. Davidson, L. Lu, M.J. Couper, D.H. StJohn, Hot tear susceptibility of Al–Mg–Si–Fe alloys with varying iron contents. Metall. Mater. Trans. A 44(12), 5396–5407 (2012)

L. Zhou, Y.D. Huang, P.L. Mao, K.U. Kainer, Z. Liu, N. Hort, Influence of composition on hot tearing in binary Mg–Zn alloys. Int. J. Cast Metal. Res. 24(3–4), 170–176 (2013)

G. Cao, I. Haygood, S. Kou, Onset of hot tearing in ternary Mg–Al–Sr alloy castings. Metall. Mater. Trans. A 41(8), 2139–2150 (2010)

G. Cao, S. Kou, Hot cracking of binary Mg–Al alloy castings. Mater. Sci. Eng. A 417(1–2), 230–238 (2006)

G. Cao, S. Kou, Hot tearing of ternary Mg–Al–Ca alloy castings. Metall. Mater. Trans. A 37(12), 3647–3663 (2006)

G. Cao, C. Zhang, H. Cao, Y.A. Chang, S. Kou, Hot-tearing susceptibility of ternary Mg–Al–Sr alloy castings. Metall. Mater. Trans. A 41(3), 706–716 (2010)

M.L. Huo, Y.C. Dai, K. Deng, Z.M. Ren, A. Gagnoud, Y. Fautrelle, R. Moreau, X. Li, Effect of sample size on twinned microstructure development in the directionally solidified Al-4.5 wt% Cu alloy. Mater. Lett. 209, 126–130 (2017)

F. Liu, L. Yang, Y. Huang, P. Jiang, G. Li, W. Jiang, X. Liu, Z. Fan, Performance of resin bonded sand for magnesium alloy casting. J. Manuf. Process. 30, 313–319 (2017)

Q.Y. Sun, D.R. Liu, J.J. Zhang, L.P. Wang, E.J. Guo, Numerical simulation of macrosegregation with grain motion during solidification of Mg-4wt.%Y alloy. Mod. Phys. Lett. B 30(36), 1650417 (2016)

Q.Y. Sun, L.P. Wang, D.R. Liu, E.J. Guo, Effects of double-procedure homogenization heat treatment on microstructure and mechanical properties of WE43A alloy. Mater. Res. Express 5(8), 086517 (2018)

J. Li, R. Chen, Y. Ma, W. Ke, Hot tearing of sand cast Mg-5 wt% Y-4 wt% RE (WE54) alloy. Acta Metall. Sin.-Engl. 26(6), 728–734 (2013)

Acknowledgements

The authors acknowledge financial support from the National Natural Science Foundation of China (Grant No. 51674094) and Natural Science Foundation of Heilongjiang Province (Grants No. E2017054).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sun, Q.Y., Liu, DR., Wang, L.P. et al. Influences of Rod Diameter and Sand-Mould Strength on Hot Tearing in Mg WE43A Constrained Rod Castings. Inter Metalcast 13, 407–416 (2019). https://doi.org/10.1007/s40962-018-0265-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-018-0265-9