Abstract

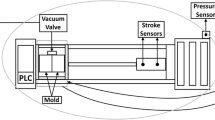

High-pressure die casting (HPDC) is one of the most important manufacturing processes. The air entrapment caused by the liquid metal flow in the slow shot phase of HPDC in a horizontal cold chamber is one of the factors that contribute to the porosity defect of die castings. The pouring of molten metal into the shot sleeve of a HPDC resembles gravity pour die casting. This stage did not receive much attention in the die casting research because it is believed that it does not play a significant role. The shot sleeve filling time depends on the amount of metal being poured and is in the range of 1–8 s. Furthermore, a common foundry practice in aluminum HPDC is to let the metal settle for a few seconds, to allow for any air bubbles to escape from the melt. This paper examines the influence of shot sleeve filling on evolution of the free surface and solidification in the HPDC machine. The numerical simulation of the free surface and solidification during the two-dimensional flow of aluminum in the horizontal cylinder and mold fillings of the HPDC machine with cold chamber was developed. The developed numerical model is based on the conservation equations of mass, momentum and energy. The moving boundary condition of the plunger movement in the injection process was considered. The tracking of the free surface is ensured by the volume of fluid (VOF) method. The enthalpy method is employed to solve the phase change heat transfer problem in the solidification process. The study examines the influence of the shot sleeve filling, the fraction filling and the time of metal settle on the evolution of the interface aluminum liquid–air profile, the mass of air imprisoned, the velocity magnitude and the temperature contours versus time.

Similar content being viewed by others

References

F. Faura, J. Lopez, J. Hernandez, On the optimum plunger acceleration law in the slow shot phase of pressure die casting machines. Int. J. Mach. Tools Manuf 41(2), 173–191 (2001)

L. Yuan, S. Xiong, B. Liu, M. Masayuki, M. Yoshihide, I. Shingo, Numerical simulation and optimization of liquid metal flow in the shot sleeve of cold chamber die casting process. In, Charles-André G, Michel B (eds) Modeling of casting, welding and advanced solidification processes-XI (2006)

T.H. Han, J.H. Kuo, W.S. Hwang, numerical simulation of the liquid-gas interface shape in the shot sleeve of cold chamber die casting machine. J. Mater. Eng. Perform. 16(5), 521–526 (2007)

Y.B. Lui, W.B. Lee, B. Ralph, A reclassification of the die-filling stages in pressure die-casting processes. J. Mater. Proc. Technol. 57, 259–265 (1996)

S. Sulaiman, A.M.S. Hamouda, D.T. Gethin, Experimental investigation for metal-filling system of pressure die casting process on a cold chamber machine. J. Mater. Process. Technol. 119, 268–272 (2001)

R. Zamora, F. Faura, J. López, J. Hernández, Experimental verification of numerical predictions for the optimum plunger speed in the slow phase of a high-pressure die casting machine. Int. J. Adv. Manuf. Technol. 33, 266–276 (2007)

A.J. Nikroo, M. Akhlaghi, M.A. Najafabadi, Simulation and analysis of flow in the injection chamber of die casting machine during the slow shot phase. Int. J. Adv. Manuf. Technol. 41, 31–41 (2009)

P.W. Cleary, J. Ha, M. Prakash, T. Nguyen, Short shots and industrial case studies, Understanding fluid flow and solidification in high pressure die casting. Appl. Math. Model. 34, 2018–2033 (2010)

L. Lavtar, M. Petric, J. Medved, B. Taljat, P. Mrvar, Simulations of the shrinkage porosity of Al-Si-Cu automotive components. Mater. Technol. 46, 177–180 (2012)

O. Yukio, Experimental verification and accuracy improvement of gas entrapment and shrinkage porosity simulation in HPDC process. Mater. Trans. 55(1), 154–160 (2014)

H. Ahuett-Garza, Allen Miller R., The effects of heat released during fill on the deflections of die casting dies. J. Mater. Proc. Technol. 142, 648–658 (2003)

H.I. Laukli, L. Arnberg, O. Lohne, Effects of grain refiner additions on the grain structures in HPDC A356 castings. Int. J. Cast Met. Res. 18, 65–72 (2005)

R. Helenius, O. Lohne, L. Arnberg, H.I. Laukli, The heat transfer during filling of a high-pressure die-casting shot sleeve. Mater. Sci. Eng. A 413, 52–55 (2005)

A.I.N. Korti, S. Abboudi, Numerical simulation of the interface molten metal air in the shot sleeve chamber and mold cavity of a die casting machine. Heat Mass Transfer 47, 1465–1478 (2011)

A.I.N. Korti, M.C. Korti, S. Abboudi, Thermal effect in minimizing air entrainment in the 3D shot sleeve during injection stage of the HPDC machine. Int. J. Fluid Mech. Res. 43(1), 1–17 (2011)

H. Bakemeyer, Operating the die casting machine, North American Die Casting Association NADCA, (2008)

L. Wang, T. Nguyen, M. Murray, Simulation of flow pattern and temperature profile in the shot sleeve of high pressure die casting process, Die casting in the 21st century October 29—November 1 Cincinnati Ohio (2001)

D.L. Youngs, Time-dependent multi-material flow with large fluid distortion, in Time-dependent multi-material flow with large fluid distortion, ed. by K.W. Morton, M.J. Baines (Academic Press, New York, 1982), pp. 273–285

W.J. Rider, D.B. Kothe, Reconstructing volume tracking. J. Comp. Phys. 141, 112–152 (1998)

V.R. Voller, C.R. Swaminathan, B.G. Thomas, Fixed grid techniques for phase change problems, a review. Int. J. Numer. Methods Eng. 30, 875–898 (1990)

A.I.N. Korti, Y. Khadraoui, A numerical simulation of the DC continuous casting using average heat capacity. Scand. J. Metall. 33, 347–354 (2004)

A.N. Korti, Y. Khadraoui, Simulation numérique du transfert thermique incluant l’ébullition nucléée lors de la coulée continue des métaux. Mécanique et Industries 7, 29–37 (2006)

I.L. Hans, High-pressure die casting of aluminium and magnesium alloys- grain structure and segregation characteristics, Thesis Norwegian University of Science and Technology (NTNU) Trondheim April, (2004)

Z. Guo, S. Xiong, B. Liu, L. Mei, A. John, Determination of the heat transfer coefficient at metal–die interface of high pressure die casting process of AM50 alloy. Int. J. Heat Mass Transf. 51, 6032–6038 (2008)

L. Lopez, J. Hernandez, F. Faura, G. Trapaga, Shot sleeve wave dynamics in the slow phase of die casting injection. ASME J. Fluids Eng. 122(2), 349–356 (2000)

S.J.K. Bukhari, M.H.K. Siddiqui, Characteristics of air and water velocity fields during natural convection. Heat Mass Transf. 43, 415–425 (2007)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Korti, A.I.N., Abboudi, S. Effects of Shot Sleeve Filling on Evolution of the Free Surface and Solidification in the High-Pressure Die Casting Machine. Inter Metalcast 11, 223–239 (2017). https://doi.org/10.1007/s40962-016-0051-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-016-0051-5