Abstract

Based on the mining conditions of shallow close coal seams in the Jurassic coalfield of northern Shaanxi, in order to explore the evolution and development height prediction of water-conducting fracture zone (WCFZ), combining with measured statistical analysis, physical simulation, numerical calculation, and theoretical analysis, the evolution of mining-induced fractures and the development characteristics of WCFZ are analyzed, and the development height predicting method of WCFZ in shallow close coal seams mining is proposed. The results show that in shallow single coal seam mining, during the stage of incritical mining, the height of the WCFZ increases in a “jumping” pattern with the main roof periodic caving. After critical mining, it is basically stable. Its development height is positively correlated with the mining height. The ratio of development height to mining height is generally 20–30, and the change is not significant with the mining height, overall, the distribution of the WCFZ is “saddle shaped”. Based on close distance coal seams repeated mining, the primary fractures act as activation development when the interburden broken completely, the development of WCFZ at the mining boundary is significantly intensified, and ratio of the height to mining height in repeated mining is obviously lower than that in single seam mining, which is generally 18–25. The traditional empirical formula cannot be applied to the development prediction in shallow close coal seams mining, with an error of 10–50%. Considering the mining height, interburden thickness, and roof caving characteristics, the development height predicting method of WCFZ in shallow close coal seams mining is proposed. Compared with measured results, the calculation error is basically within 15%, which has good prediction accuracy, The research results can provide a theoretical basis for predicting the height of WCFZ in shallow close coal seams mining in the Jurassic coalfield of northern Shaanxi.

Article Highlights

-

Combining with multiple research methods, the development characteristics of water-conducting fracture zone (WCFZ) are analyzed, and the development height predicting method of WCFZ in shallow close coal seams mining is proposed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The Jurassic coalfield of northern Shaanxi is one of the seven largest coalfields in the world. The coalfield is characterized by shallow buried coal seams and closely interburden. Currently, the top coal seam of most mining areas has been extracted, while the lower coal seam is being mined. Mining practice has shown that during shallow close coal seam mining, after the interval rock strata lose stability, the original overburden fractures are activated and developed, and the concentrated fractures may cut through the aquifer during repeated mining, resulting in mine water damage and threatening safe and green mining (Wang 2021). Therefore, studying the evolution law of WCFZ in shallow close coal seams mining and proposing a method for height prediction of WCFZ suitable for repeated mining in this area has great theoretical significance and practical value.

Scholars have conducted extensive research on the development laws of overburden fractures in shallow close coal seams mining (Yao et al. 2010; Wang et al. 2013; Yu et al. 2018; Huang et al. 2019; Cao and Huang 2021; Li et al. 2016). In terms of height prediction of WCFZ in single coal seam mining, China mainly relies on traditional empirical formulas from Regulations for the retention and mining of coal pillars in buildings, water bodies, railways, and main shafts and tunnels (Administration and of Safety 2017), as well as Evaluation standards for hydrogeology, engineering geology and environmental geology exploration of coal deposits (Standard for Exploration and Evaluation of Hydrogeology 2009). Besides, Xu et al. (2012) applied the theory of key strata to estimate the development height of WCFZ. Huang (2017) found that the development height of the WCFZ in Shenfu Mine Area is generally 18–28 times the mining height in single seam mining. Du et al. (2021) used optical fiber sensing technology to monitor the development height of WCFZ. By using the ground drilling flushing fluid leakage method, Guo et al. (2019) determined the development height of WCFZ in top coal caving face. In addition, physical simulation, numerical calculation and other methods are also widely used in the research of WCFZ height. With regard to the prediction of WCFZ height for repeated mining, Li et al. (2017) estimated the height of WCFZ based on key strata locations and proposed the concept of an equivalent cumulative mining height for lower coal seams. Based on the comprehensive mining thickness, Pan et al. (2017) used the traditional empirical formula of WCFZ to predict the development height of fracture zone in close coal seams mining. Wei et al. (2022) studied the influence of multi-seams mining on the WCFZ. Luan et al. (2022) studied the WCFZ in repeated mining by using the methods of empirical formula, field measurement and numerical simulation.

The practice has shown that the traditional empirical formula of WCFZ height is not applicable to the shallow coal seams mining in Jurassic coalfield of northern Shaanxi, as it results in significant errors when compared with measured values. Currently, there is a dearth of anticipated research findings on the WCFZ height in close coal seams mining. Moreover, the mining conditions in the study area are unique, with many regions covered by thick loose layer. Therefore, it is imperative to conduct specific research in this regard. In this paper, statistical analysis, physical simulation, numerical calculation and theoretical analysis are used to analyze the measured law of the WCFZ height of shallow close coal seams mining in Jurassic coalfield of northern Shaanxi. The study reveals the fracture characteristics and development patterns of WCFZ height, and proposes a prediction method for WCFZ height in this area.

2 Overview of the research area and measured analysis of WCFZ height

2.1 Geological overview of the research area

The Jurassic Coalfield of northern Shaanxi is located in the air and semi-arid areas of northwest China, where the ecological environment is fragile. The coal seams are characterized by a shallow burial depth in the east and deeper depths towards the west, with depths ranging from less than 40 m to as much as 580 m at its deepest point. There are typically 3–5 layers of medium-thick coal seams with the interburden thickness generally within 40 m, which belongs to shallow close coal seams mining.

The overburden thickness above the coal seam shows a certain regularity, which gradually becomes thicker from east to west. The main type of overburden is medium-hard rock. In this area, the main aquifer is sand layers, and the main impermeable layer is Lishi loess and Sanzhima laterites. The thickness of the soil layer is generally between 20 and 175 m. The loess is primarily distributed in Xinmin Area and exposed on the surface, while the laterites is mainly distributed in Yu Shen Mining Area, between the Salawusu Formation aquifer and the bedrock. The No. 1–2 coal seam, No. 2–2 coal seam, and No. 3–1 coal seam are the main minable coal seams in the coalfield. The distribution characteristics of coal seams thickness and water resources are shown in Fig. 1.

2.2 Measured law of the WCFZ height in shallow close coal seams mining

The height development law of WCFZ is the fundamental research basis for coal green mining in this area, and the measured analysis of WCFZ height can provide a crucial foundation for theoretical prediction method. Therefore, the authors have counted the observation statistics of WCFZ height in shallow single coal seam mining and repeated mining, as shown in Table 1 (In Caojiatan, Yushuwan, and Ningtiaota mines, there are different mining areas of the same coal seam).

-

(1)

Measured analysis of WCFZ height in single coal seam mining

According to Table 1, Fig. 2 shows the relationship between the WCFZ height, ratio of its height to mining height, and mining height in single coal seam mining. The analysis indicates that the height of WCFZ increases with the increase in coal seam mining height, and the range of ratio of the height to mining height is generally between 20 and 30. In other words, the height of WCFZ is typically 20–30 times that of the mining height, however, the change of the ratio mentioned above with mining height is not significant.

-

(2)

Measured analysis of WCFZ height in close coal seams repeated mining.

According to Table 1, Fig. 3 shows the relationship between the WCFZ height, ratio of the WCFZ height to mining height and sum of the two coal seams mining heights in repeated mining. The following conclusions can be drawn:

-

①

In close coal seams repeated mining, the activation and development of overburden fractures becomes more obvious, and the WCFZ height further increases.

-

②

The ratio of the WCFZ height to mining height in repeated mining is obviously smaller than that in single coal seam mining. The range of ratio is generally 10–30, mostly between 18 and 25. That is to say, the WCFZ height is generally 18–25 times of the sum of the two coal seam mining heights, and its change with the sum of the mining heights is not obvious. It can be seen that the fractures development in repeated mining is less than that of the same coal seam thickness disposable mining.

3 Law of mining-induced fractures and WCFZ height in single coal seam

3.1 Law of mining-induced fractures and WCFZ height in Daliuta No. 1–2 upper coal seam

-

(1)

Design of physical simulation experiment and numerical calculation.

The Huojitu Well coal seam in Daliuta Mine is characterized by shallow buried and small interburden thickness, which belongs to shallow close coal seams mining. The majority of the surface area is covered with soil layer. The average thickness of the No. 1–2 upper coal seam is 4 m, with a buried depth of 72.96 m. Among them, the thickness of bedrock is 51.17 m, the thickness of the loose soil layer is 21.79 m, the thickness of No. 1–2 coal seam is 5 m, and the interburden thickness between the two coal seams is 21.31 m.

In order to study the evolution law of overburden fractures and WCFZ height in the single coal seam mining, also the repeated mining of the lower coal seam mining. A physical simulation experiment was established, and the geometric similarity ratio is 1:100, the model length × width × height = 1.5 m × 0.16 m × 1.09 m. For rock layer, sand was used as the aggregates, gypsum and calcium carbonate were adopted as cementitious materials, mica powder was used to simulate tectonic fissure. For soil layer, sand and bentonite were used as the aggregates, and silicone oil was adopted as cementitious material. Firstly, the No. 1–2 upper coal seam was mined, after the rock strata collapse and stabilize, the lower No. 1–2 coal seam was mined. The physical simulation model is shown in Fig. 4a.

The 3DEC numerical calculation model was established with dimensions of length × width × height = 150 m × 16 m × 109 m (Fig. 4b). The Mohr–Coulomb constitutive model was utilized, while the joint constitutive model selected was Coulomb slip. The excavation scheme was the same as the physical simulation.

-

(2)

Development law of mining-induced fractures and WCFZ height.

When the longwall face advances to 46 m, the main roof caves for the first time, the overburden caving angle is 55° on the side of open-off cut, while it is 58° on the side of longwall face wall. At this time, the height of WCFZ reaches 17 m of the longwall face roof (Fig. 5).

As the longwall face continues to advance to 54 m, 64 m and 76 m, the main roof of the longwall face caves periodically, and the WCFZ develops upward accordingly. When the longwall face advances to 120 m, the mining-induced fractures develop through the ground surface. Under the tensile force caused by overburden caving, there are downward fractures generated (cracks developed from top to bottom) on the mining boundary, as shown in Fig. 6.

The relationship between the WCFZ height and the advance of No. 1–2 upper coal seam longwall face is shown in Fig. 7.

During the subcritical mining stage(As the longwall face advances, the ground surface subsidence gradually increases, and it do not reach its maximum value), the increase of WCFZ height shows as 'jumping' with the main roof periodic caving of the longwall face. After the longwall face reaches critical mining (The ground surface subsidence has reached the maximum value, as the longwall face continues to advance, it remains basically unchanged), the overburden fractures have developed to the surface, the height of WCFZ is stable, and ratio of the WCFZ height to mining height is 18.3. With the continuous mining, the overburden fractures show a periodic change process of “fracture generation (in front of the coal wall)-fracture development (continuous mining)-fracture closure (after mining)”.

3.2 Law of mining-induced fractures and WCFZ height in Halagou 1–2 upper coal seam

-

(1)

Design of physical simulation experiment and numerical calculation.

The No. 1–2 upper coal seam and No. 1–2 coal seam in Halagou coal mine belong to shallow close coal seams mining. The thickness of No. 1–2 upper coal seam is 2 m, and the buried depth is 49.74 m, the thickness of bedrock is 38.4 m, the thickness of soil layer is 1.6 m, the thickness of aeolian sand is 9.74 m. The thickness of No. 1–2 coal seam is 2 m, and the interburden thickness between the two coal seams is 9.04 m.

In order to study the evolution law of overburden fractures and WCFZ height in the single coal seam mining, also the repeated mining of the lower coal seam mining. A physical simulation model was established, and the geometric similarity ratio is 1:100, the model length × width × height = 2.0 m × 0.2 m × 0.66 m. The No. 1–2 upper coal seam was first mined, followed by the lower No. 1–2 coal seam was mined. The model is shown in Fig. 8a. The 3DEC numerical calculation model was established, with the size was length × width × height = 200 m × 20 m × 66 m, as shown in Fig. 8b.

-

(2)

Development law of mining-induced fractures and WCFZ height.

When the longwall face advances to 44 m, the main roof caves for the first time, and the WCFZ height is 11.5 m, as shown in Fig. 9. When the longwall face advances to 74 m, the critical mining is achieved, and the WCFZ has developed to the top of the aeolian sand layer (the surface), which is mainly concentrated on both sides of the longwall face. The middle of the goaf is compacted by the overburden, and the separation layer fractures tend to be closed. Overall, its distribution is 'saddle shaped', as shown in Fig. 10. The relationship between the WCFZ height and the mining of the No. 1–2 upper coal seam is shown in Fig. 11, and the ratio of the WCFZ height to mining height is 24.9.

Fig. 9 Fig. 10

4 Law of mining-induced fractures and WCFZ height in repeated mining

4.1 Law of mining-induced fractures and WCFZ height in Daliuta 1–2 coal seam repeated mining

When the longwall face advances to 54 m, the interburden between the two seams is broken for the first time, the goaf of the upper and lower coal seams are collapsed, the original fractures after the No. 1–2 upper coal mining are activated and developed, and the development of the boundary fractures is increased. The overburden fractures caving angle of the lower coal seam mining is about 70°, as shown in Fig. 12.

After the longwall face reaches critical mining, the overburden fractures develop to the surface, and the height of the WCFZ is 98.27 m, which is 11 times the sum of the mining height of the two coal seams. The original fractures in the single coal seam mining are activated and developed, especially the concentrated development of the WCFZ at the mining boundary of the longwall face is significantly intensified, the overburden in the middle of the goaf is re-compacted, and the separation layer fractures tend to be closed. Under the influence of repeated mining, the depth and width of the surface downward fractures are further increased, as shown in Fig. 13.

4.2 Law of mining-induced fractures and WCFZ height in Halagou 1–2 coal seam repeated mining

When the longwall face advances to 30 m, the interbuden is completely broken, the goaf of the upper and lower coal seam longwall face is connected, and the original overburden fractures are activated and developed (Fig. 14). It can be known that it is difficult to form the key strata structure in the interburden when the ratio of the interburden thickness to the mining height of the lower coal seam (9.04 m/2 m) is small, so the completely broken step distance of the interburden becomes smaller.

As the longwall face continues to advance, the interburden are caved immediately with mining, and the development of the WCFZ on the side of the open-off cut increases gradually with the advance, and it is stable when the longwall face becomes achieves critical mining. While the WCFZ on the side of the longwall face wall is in a dynamic change process. With the interburden broken, the overburden fractures formed by No. 1–2 upper coal mining are activated and developed. With the longwall face advances, the fractures grow from small to large, and gradually changes from large to close after the advance. After the longwall face mining, the WCFZ still presents a 'saddle shape' distribution. The development of the WCFZ on both sides of the 'saddle' (including longitudinal fractures and separation fractures) is significantly increased, which is the main channel to cut through the aquifer with the longwall face. The longitudinal fractures in the middle are not developed, and the separation fractures are closed, as shown in Fig. 15.

5 Prediction method of WCFZ height in shallow close coal seams mining

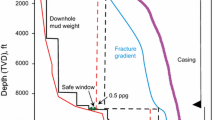

5.1 Traditional prediction method of WCFZ height in coal seam mining

At present, the widely used prediction formula of WCFZ height in single coal seam mining is listed as follows: ① Empirical formula of Buildings, Water Bodies, Railways and Main Roadway Coal Pillar Setting and Coal Mining Regulations (Administration and of Safety 2017). ② Empirical formula of Standard for Exploration and Evaluation of Hydrogeology, Engineering Geology and Environment Geology in Coal Beds (Standard for Exploration and Evaluation of Hydrogeology 2009). ③ Empirical formula of Coal Pillar Setting and Coal Mining in Buildings, Water Bodies, Railways and Main Roadways (Hu et al. 2017). ④ Empirical formula of Tangshan Coal Research Institute (Beijing Mining Research Institute 1981). ⑤ Empirical formula of China University of Mining and Technology (Xu et al. 2011). The last three empirical formulas are mainly applied to fully mechanized caving mining conditions of thick coal seam. Now, the first two prediction methods are the most widely used.

The overburden is mainly medium-hard rocks in the research area. Therefore, the empirical formula under the condition of medium-hard rocks in the Three Regulations and Evaluation Standard for Hydrogeological Exploration is used to calculate WCFZ height, as shown in Table 2 ("−" means less than the measured value). The analysis shows that:

-

①

The error between the calculated results of Three Regulations empirical formula 1 and the measured values is basically more than 30%, and ratio of the WCFZ height to mining height calculated by this formula (generally 10–20) is significantly smaller than that measured value. The error between the calculated results of empirical formula 2 and the measured values is basically more than 10%, and the calculated results of WCFZ heigh and ratio of the WCFZ height to mining height are generally smaller, but the error of formula 2 is slightly smaller than that of formula 1.

-

②

The error between the calculated results of the empirical formula of Evaluation Criteria for Hydrogeological Exploration and the measured values is basically 30–45%, and ratio of the WCFZ height to mining height is about 15, which is significantly lower than the measured values.

In summary, based on the mining conditions of shallow close coal seams in Jurassic coalfield of northern Shaanxi, the WCFZ height calculated by traditional empirical formula is very different from the measured value, and the calculated results are obviously smaller. This is because the overburden conditions in the research area are special, the bedrock is relatively thin, and many areas are covered with thick soil layers and loose sand layers. Therefore, the WCFZ develops strongly in the actual mining engineering, and the WCFZ height is relatively large, even to the surface.

It can be known that the traditional formula cannot be well applied to the prediction of WCFZ height in shallow close coal seams mining. Therefore, it is necessary to study the prediction formula of WCFZ height suitable for shallow close coal seams mining.

5.2 Fitting formula of WCFZ height in shallow close coal seams mining

-

(1)

Prediction formula of WCFZ height in single coal seam mining.

The overburden conditions in the research area are mainly medium-hard. According to Table 1, based on the measured data, the regression analysis is carried out. By referring to the basic form of empirical formula 1 (Formula 1) in Three Regulations, a unitary linear regression model is established to predict the WCFZ height.

where H is the WCFZ height, m. M is mining height, m. a and b are the coefficients. ± m is the error, it can be determined by Bessel formula \(\sqrt {\frac{{\left[ {VV} \right]}}{n - 1}}\) (n is the number of measurements; V is the residual error).

Transform the empirical formula into:

Let \(\frac{1}{H} = y\), \(\frac{1}{M} = x\), then formula (2) becomes:

Based on the measured data (the first 16 groups) and formula (3) in single coal seam mining in Table 1, the linear fitting function of y and x is obtained, as shown in Fig. 16 (that is, the function expression of reciprocal of WCFZ height and reciprocal of mining height).

According to Fig. 16, y = 0.03006x + 0.00163. Combined with formula (3), it can be obtained that a = 0.163, b = 3.006. Therefore, there are:

By substituting the mining height value of the upper coal seam in Table 1 into formula (4), the prediction value of WCFZ height can be obtained, as shown in Table 3.

Compared with the measured value of WCFZ height, the standard deviation is obtained by Bessel formula (Formula 5):

According to formula (5), m = 10.1.

Therefore, the prediction formula of WCFZ height in shallow buried single coal seam mining is:

-

(2)

Prediction formula of WCFZ height in repeated mining.

After mining of shallow single coal seam, overburden generally presents the characteristics of "two zones", that is, overburden caving zone and fracture zone, and there is no bending subsidence zone. During the lower coal seam repeated mining, the "original fracture" of overburden is activated and developed again, the development width of the overburden fracture increases, and the WCFZ height increases. Under this condition, the prediction of WCFZ height should consider the influence factors of mining height, interburden thickness and roof caving characteristics of upper and lower coal seams. Besides, the factors above should be converted into a comprehensive mining height that can reflect the superimposed effect of repeated mining. Pan et al. (2017) provides the calculation formula of comprehensive mining height of close distance double coal seam mining:

where M1 is the mining height of the upper coal seam, m. M2 is the mining height of the lower coal seam, m. ∑M is the comprehensive mining height, m. k is the subsidence coefficient at the top of the interburden in the lower coal seam mining. h is interburden thickness, m. Hm is the buried depth of the lower coal seam, m. \(k^{\prime}\) is the surface subsidence coefficient related to the degree of mining, which can be determined by the calculation formula in reference (Wang et al. 1998):

where, S is the thickness of the soil layer in the ground surface, m.

According to the measured data (17–27) and formula (7)-formula (9) of repeated mining in shallow close coal seams in Table 1, the comprehensive mining height of repeated mining can be calculated (Table 4).

Similarly, it is assumed that the basic form of the WCFZ formula for repeated mining of shallow close coal seams is:

where \(H^{\prime}\) is the WCFZ height after repeated mining, m. \(a^{\prime}\) and \(b^{\prime}\) is the coefficient. \(\pm m^{\prime}\) is the error.

Transform the empirical formula into:

Let \(\frac{1}{{H^{\prime}}} = y^{\prime}\), \(\frac{1}{\Sigma M} = x^{\prime}\), and then formula (11) becomes:

According to the measured data (17–27) and formula (12) of repeated mining in Table 1, the linear fitting function of \(y^{\prime}\) and \(x^{\prime}\) is obtained as shown in Fig. 17.

Therefore, \(y^{\prime} = 0.0627x^{\prime} - 0.0032\), combined with formula (12), \(a^{\prime} = - 0.32\), \(b^{\prime} = 6.27\). Therefore, there are:

By substituting the obtained comprehensive mining height value into formula (13), the prediction value of WCFZ height under repeated mining can be obtained, and compared with the measured value of WCFZ height (Table 4). The standard deviation \(m^{\prime} = 21.1\) can be obtained by using Bessel formula.

Therefore, the prediction formula of WCFZ height in repeated mining in shallow close coal seams is:

6 Conclusion

-

(1)

shallow single coal seam mining in Jurassic coalfield of northern Shaanxi, the WCFZ height is positively correlated with the mining height, and ratio of the WCFZ height to mining height is generally 20–30, which does not change significantly with the mining height. With repeated mining in shallow close coal seams, the activation and development of overburden fractures are intensified, and the WCFZ height continues to increase. The ratio of the WCFZ height to mining height in repeated mining is obviously lower than that in single seam mining, which is generally 18–25.

-

(2)

In the incritical mining stage of shallow single coal seam mining, the height of the WCFZ increases in a "jumping" pattern with the main roof periodic caving. After critical mining, it is basically stable. The WCFZ is concentrated in the mining boundary. The middle of the goaf is compacted by the overburden, and the separation fractures tend to close. The whole distribution shows as “saddle shape”, and there are downward cracks on the ground surface.

-

(3)

Based on close coal seams repeated mining, the primary fractures act as activation development when the interburden broken completely, the development of WCFZ at the mining boundary is significantly intensified. The depth and width of the downward fractures on the surface increase further.

-

(4)

The traditional empirical formula cannot be well applied to the development prediction in shallow close coal seams mining, with an error of 10–50%. The predicting method of WCFZ height is proposed, which is suitable for shallow close coal seams mining in Jurassic coalfield of northern Shaanxi. The calculation error is basically within 15%, which has good prediction accuracy.

Availability data and materials

The authors confirm that the data supporting the findings of this study are available within the article.

References

Beijing Mining Research Institute, Coal Research Institute. Law of surface movement and overlying rock failure in Coal mine and its application. Coal Industry Press, Beijing (1981)

Cao J, Huang Q (2021) Regularity and control of overburden and surface fractures in shallow-contiguous seams. Coal Geol Explor 49(04):213–220

Du W, Chai J, Zhang D et al (2021) Optical fiber sensing and characterization of water flowing fracture development in mining overburden. J China Coal Soc 46(05):1565–1575

Guo W, Lou G, Zhao B (2019) Study on the height of water-conductive fracture zone in alternate overburden of soft and hard with top coal caving mining in Lugou coal mine. J Min Saf Eng 36(03):519–526

Hu B, Zhang H, Shen B (2017) Guide for coal pillar setting and coal mining in buildings, water bodies, railways and main roadways. Coal Industry Press, Beijing

Huang Q (2017) Research on roof control of water conservation mining in shallow seam. J China Coal Soc 42(01):50–55

Huang Q, Dun J, Hou E et al (2019) Research on overburden and ground surface cracks distribution and formation mechanism in shallow coal seams group mining. J Min Saf Eng 36(01):7–15

Li S, Ding Y, An Z et al (2016) Experimental research on the shape and dynamic evolution of repeated mining-induced fractures in short-distance coal seams. J Min Saf Eng 33(05):904–910

Li Q, Ju J, Cao Z et al (2017) Suitability evaluation of underground reservoir technology based on the discriminant of the height of water conduction fracture zone. J China Coal Soc 42(08):2116–2124

Luan Y, Yu S, Guo C et al (2022) Study on development of water-flow fractured zone during close-distance repeated coal mining. Coal Technol 41(05):115–118

Pan R, Cao S, Li Y et al (2017) Development of overburden fractures for shallow double thick seams mining. J China Coal Soc 42(08):2116–2124

Standard for Exploration and Evaluation of Hydrogeology, Engineering Geology and Environment Geology in Coal Beds: MT/T 1091-2008[S]. 2009.

State Administration of Safety, State Administration of Coal Mine Safety, National Energy Administration, National Railway Administration. Buildings, water bodies, railways and main roadway coal pillar setting and coal mining regulations. Coal Industry Press, Beijing (2017)

Wang Y, Deng K, Zhang D et al (1998) The study on the character of strata subsidence during repeat mining. J China Coal Soc 05:24–29

Wang W, Sui W, Dong Q et al (2013) Closure effect of mining-induced fractures under sand aquifers and prediction of overburden failure due to re-mining. J China Coal Soc 38(10):1728–1734

Wang Y (2021) Research on the dynamic law of overlying strata failure in shallow burying and short distance double coal seam mining. China University of Mining and Technology

Wei S, Zhao Y, Qi C et al (2022) On development law of water conducting fracture zone and overburden failure height in multi-coal seam mining. J Hunan Univ Sci Technol 37(02):18–26

Xu Y, Li J, Liu S et al (2011) Calculation formula of “Two zone” height of overlying strata and its adaptability analysis. Coal Min Technol 16(02):4–7

Xu J, Zhu W, Wang X (2012) New method to predict the height of fractured water-conducting zone by location of key strata. J China Coal Soc 37(05):762–769

Yao B, Zhou H, Chen L (2010) Numerical simulation about fracture development in overlying rocks under repeated mining. J Min Saf Eng 27(03):443–446

Yu M, Teng F, Chu T et al (2018) Simulation study on the evolution of the overlying strata fractures and air-leaking passage under repeated mining of shallow buried coal seams. J Henan Polytech Univ 37(01):1–7

Acknowledgements

We thank the academic editors and anonymous reviewers for their kind suggestions and valuable comments.

Funding

This research was funded by the Natural Science Foundation of Inner Mongolia of China, Grant number No. 2022QN05007, and the National Natural Science Foundation of China, Grant number No. 51964037, and Introduce Excellent Talents Support Project of Inner Mongolia, Grant number No. 0701012101.

Author information

Authors and Affiliations

Contributions

CJ and SH wrote the main manuscript text, CJ and LJ prepared figures, and CJ and WC prepared tables. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

The authors declare that the submitted work is original and has not been submitted to more than one journal for simultaneous consideration.

Consent to publish

The authors agree to publication in the Geomechanics and Geophysics for Geo-Energy and GeoResources and also to publication of the article in English by Springer in Springer’s corresponding English-language journal.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Cao, J., Su, H., Wang, C. et al. Research on the evolution and height prediction of WCFZ in shallow close coal seams mining. Geomech. Geophys. Geo-energ. Geo-resour. 9, 128 (2023). https://doi.org/10.1007/s40948-023-00662-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40948-023-00662-9