Abstract

The edge strength of annealed float glass is an essential aspect in engineering design. A common problem in engineering applications is the failure of the edge due to thermally induced stresses. The edge strength of annealed glass is affected by cutting, further processing and handling. Thermally treated glass exhibits higher edge strengths, but may show optically negative effects such as anisotropy and roller waves. In case of covered edges, e.g. insulating glass covered by framing, an enhanced strength of the cut edge is desirable. This paper presents results showing that enhanced strength of the cut edge is feasible and reproducible using regular cutting technology. A large part of this contribution deals with the crack system resulting from the cutting process. A deep understanding of this is essential for the relationship between cutting parameters, damage and edge strength. In addition to optical microscopic analyses, confocal microscopy and indentation tests have been carried out. The influence of different cutting process parameters on the edge strength was investigated within the scope of extensive analyses by the Fachverband Konstruktiver Glasbau e.V. This allowed to adjust selected process parameters so that the edge strength could be reproducibly enhanced. In this contribution the latest results of these investigations are presented. In addition, the correlation between microscopic optical characteristics and the mechanical strength as expressed by the macroscopic fracture stress is described.

Similar content being viewed by others

References

Bundesverband Flachglas: Leitfaden für thermisch gebogenes Glas im Bauwesen, BF-Merkblatt 009/2011 (2011)

Brokmann, C., Alter, C., Kolling, S.: Experimental determination of failure strength in automotive windscreens using acoustic emission and fractography. Glass Struct. Eng. (2018). https://doi.org/10.1007/s40940-018-0090-9

Cook, R.F., Pharr, G.M.: Direct observation and analysis of indentation cracking in glasses and ceramics. J. Am. Ceram. Soc. 73(3), 787–817 (1990)

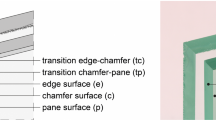

DIN 1249-11: Flachglas im Bauwesen-Glaskanten, Begriffe, Kantenformen und Ausführung. Beuth, Berlin (2017)

DIN 18008-1: Glas im Bauwesen–Bemessungs- und Konstruktionsregeln–Teil 1: Begriffe und allgemeine Grundlagen. Beuth, Berlin (2010)

EN 1288-1: Glass in Building-Determination of the Bending Strength of Glass-Part 1: Fundamentals of Testing Glass. Beuth, Berlin (2000a)

EN 1288-3: Glass in Building-Determination of the Bending Strength of Glass-Part 3: Test with Specimen Supported at Two Points (Four Point Bending). Beuth, Berlin (2000b)

EN ISO 4288: Geometrical Product Specifications (GPS)-Surface Texture: Profile Method-Rules and Procedures for the Assessment of Surface Texture. Beuth Verlag, Berlin (1998)

EN ISO 16610-61: Geometrical Product Specification (GPS)-Filtration-Part 61: Linear Areal filters: Gaussian filters. Beuth Verlag, Berlin (2016)

Ensslen, F., Müller-Braun, S.: Kantenfestigkeit von Floatglas in Abhängigkeit von wesentlichen Schneidprozessparametern, Glasbau 2017. Ernst & Sohn, Berlin (2017)

Jebsen-Marwedel, H., von Stösser, K.: Der Mechanismus des Schneidens von Glas und die Schwächung des Glases durch den Schnitt, Glastechnische Berichte 17, Deutsche Glastechnische Gesellschaft e.V., Frankfurt am Main (1939)

Kleuderlein, J., Ensslen, F., Schneider, J.: Untersuchung zur Kantenfestigkeit von Floatglas in Abhängigkeit der Kantenbearbeitung, Glasbau 2016. Ernst & Sohn, Berlin (2016)

Lindqvist, M.: Structural glass strength prediction based on edge flaw characterization. Dissertation, École Polytechnique Fédéreale de Lausanne (2013)

Müller-Braun, S., Franz, J., Schneider, J., Schneider, F.: Optische Merkmale der Glaskante nach Glaszuschnitt mit Schneidrädchen, Glasbau 2018. Ernst & Sohn, Berlin (2018)

Quinn, G.D.: Fractography of Ceramics and Glasses. National Institute of Standards and Technology, Washington, DC (2007)

Schneider, J., Kuntsche, J.K., Schula, S., Schneider, F., Wörner, J.-D.: Glasbau Grundlagen, Berechnung, Konstruktion. Springer, Berlin (2016)

Schula, S.: Charakterisierung der Kratzanfälligkeit von Gläsern im Bauwesen, Dissertation, Technische Universität Darmstadt, Springer (2014)

Vandebroek, M.: Thermal fracture of glass. Dissertation, Universiteit Ghent (2014)

Wiederhorn, S.M.: Influence of water vapor on crack propagation in soda-lime glass. J. Am. Ceram. Soc. 50(8), 407–414 (1967)

Acknowledgements

The authors would like to thank the Fachverband Konstruktiver Glasbau e.V. (FKG) for their support, especially to the members of the working group Edge Strength who made it possible to support this project by providing the test specimens, accompanying the tests and documenting the production parameters.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Müller-Braun, S., Seel, M., König, M. et al. Cut edge of annealed float glass: crack system and possibilities to increase the edge strength by adjusting the cutting process. Glass Struct Eng 5, 3–25 (2020). https://doi.org/10.1007/s40940-019-00108-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40940-019-00108-3