Abstract

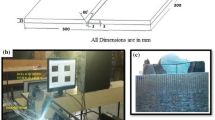

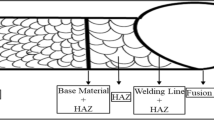

This study involves experimental and numerical investigation on ballistic performance of ultra-high hard armour (UHHA) steel joints fabricated using shielded metal arc welding (SMAW) process and austenitic stainless steel (ASS) electrodes. The ballistic test of UHHA-steel butt joints involves subjecting welded joints to 7.62 mm armor-piercing (AP) small arm projectiles. The weld metal (WM) and the weld interface (WI) are the areas of interest for the impact in ballistic test. The simulation approach of finite element analysis (FEA) that incorporates the model of Johnson–Cook and Mie Gruneisen equation of state (EOS) for the equations of velocity—Shock Rankine-Hugoniot. The scanning electron microscopy was employed to analyze the microstructure and ballistically tested regions of UHHA-steel butt joints. The hardness of the different regions of UHHA-steel joint was estimated using Vickers microhardness test. The results disclosed that the AP projectiles were arrested at the WM and WI, each exhibiting distinct depth of penetration (DoP) and width of penetration (WoP). These results align well with the FE model predictions. During projectile impact, a ductile hole growth was observed as plastic deformation pushes the material outward. When an AP projectile strikes, striations appear on the target plate's surface, observed both experimentally and in FE simulations. Additionally, the AP projectile becomes lodged at the WM. At the interface, the WM absorbs the projectile's movement, while the harder heat-affected zone (HAZ) disrupts the trajectory due to the soft/hard (austenite/martensite) interface. This behavior is elucidated by examining the WoP in impact region within the FE model.

Similar content being viewed by others

Data Availability

All data generated or analyzed during this study are included in this article.

Abbreviations

- RHA steel:

-

Rolled homogeneous armour steel

- UHHA steel:

-

Ultra-high hard armour steel

- HIC:

-

Hydrogen induced cracking

- SMAW:

-

Shielded metal arc welding

- ASS:

-

Austenitic stainless steel

- AP projectile:

-

Armour piercing projectile

- FEA:

-

Finite element analysis

- WM:

-

Weld metal

- HAZ:

-

Heat affected zone

- BM:

-

Base metal

- WI:

-

Weld interface

- SLR:

-

Self-loading type of rifle

- IT:

-

Impact toughness

- EOS:

-

Equation of state

- DoP:

-

Depth of penetration

- WoP:

-

Width of penetration

References

Saleh M, Luzin V, Kariem MA, Thorogood K, Ruan D (2020) Experimental measurements of residual stress in ARMOX 500T and evaluation of the resultant ballistic performance. J Dyn Behav Mater 6:78–95

Nathan SR, Balasubramanian V, Rao AG, Sonar T, Ivanov M, Suganeswaran K (2023) Effect of tool rotational speed on microstructure and mechanical properties of friction stir welded DMR249A high strength low alloy steel butt joints for fabrication of light weight ship building structures. Int J Lightweight Mater Manuf 6(4):469–482

Nathan SR, Balasubramanian V, Gourav Rao A, Sonar T, Ivanov M, Rajendran C (2023) Influence of tool plunging rate on mechanical properties and microstructure of friction stir welded DMR249A high strength low alloy (HSLA) steel butt joints. Mater Test 65(10):1528–1538

Naveen Kumar S, Balasubramanian V, Malarvizhi S, Hafeezur Rahman A, Balaguru V (2021) Influence of microstructural characteristics on ballistic performance and its mode of failure in shielded metal arc welded ultra-high hard armor steel joints. Trans Indian Inst Met 74:909–921

Naveen Kumar S, Visvalingam B, Sudersanan M, Abdur HR, Vadivel B (2021) Influence of welding consumables on ballistic performance of gas metal arc welded ultra-high hard armor steel joints. Mater Perform Charact 10(1):443–462

Kumar KS, Arivazhagan N (2024) An innovative pulsed current arc welding technology for armor steel: processes, microstructure, and mechanical properties. Mater Today Commun 38:108237

Magudeeswaran G, Balasubramanian V, Reddy GM (2008) Hydrogen induced cold cracking studies on armour grade high strength, quenched and tempered steel weldments. Int J Hydrogen Energy 33(7):1897–1908

Naveen Kumar S, Balasubramanian V, Malarvizhi S, Hafeezur Rahman A, Balaguru V (2022) Effect of welding consumables on the ballistic performance of shielded metal arc welded dissimilar armor steel joints. J Mater Eng Perform 31:162–179

Balaguru V, Balasubramanian V, Sivakumar P (2020) Effect of weld metal composition on impact toughness properties of shielded metal arc welded ultra-high hard armor steel joints. J Mech Behav Mater 29(1):186–194

Karagöz Ş, Atapek ŞH, Yilmaz A (2010) Microstructural and fractographical studies on quenched and tempered armor steels. Mater Test 52(5):316–322

Jena PK, Mishra B, RameshBabu M, Babu A, Singh AK, SivaKumar K, Bhat TB (2010) Effect of heat treatment on mechanical and ballistic properties of a high strength armour steel. Int J Impact Eng 37(3):242–249

Maweja K, Stumpf W (2008) The design of advanced performance high strength low-carbon martensitic armour steels: microstructural considerations. Mater Sci Eng, A 480(1–2):160–166

Jena PK, Kumar KS, Krishna VR, Singh AK, Bhat TB (2008) Studies on the role of microstructure on performance of a high strength armour steel. Eng Fail Anal 15(8):1088–1096

Magudeeswaran G, Balasubramanian V, Balasubramanian TS, Reddy GM (2008) Effect of welding consumables on tensile and impact properties of shielded metal arc welded high strength, quenched and tempered steel joints. Sci Technol Weld Join 13(2):97–105

Børvik T, Dey S, Clausen AH (2009) Perforation resistance of five different high-strength steel plates subjected to small-arms projectiles. Int J Impact Eng 36(7):948–964

Børvik T, Langseth M, Hopperstad OS, Malo KA (2002) Perforation of 12 mm thick steel plates by 20 mm diameter projectiles with flat, hemispherical and conical noses: Part I: experimental study. Int J Impact Eng 27(1):19–35

Børvik T, Hopperstad OS, Langseth M, Malo KA (2003) Effect of target thickness in blunt projectile penetration of Weldox 460 E steel plates. Int J Impact Eng 28(4):413–464

Dey SA, Børvik T, Hopperstad OS, Leinum JR, Langseth M (2004) The effect of target strength on the perforation of steel plates using three different projectile nose shapes. Int J Impact Eng 30(8–9):1005–1038

Mohammad Z, Gupta PK, Baqi A, Iqbal MA (2021) Ballistic performance of monolithic and double layered thin-metallic hemispherical shells at normal and oblique impact. Thin-Walled Struct 159:107257

Flores-Johnson EA, Saleh M, Edwards L (2011) Ballistic performance of multi-layered metallic plates impacted by a 7.62-mm APM2 projectile. Int J Impact Eng 38(12):1022–1032

Flores-Johnson EA, Muránsky O, Hamelin CJ, Bendeich PJ, Edwards L (2012) Numerical analysis of the effect of weld-induced residual stress and plastic damage on the ballistic performance of welded steel plate. Comput Mater Sci 58:131–139

NATO STANAG 4569 (2004) Protection levels for occupants of logistic and light armoured vehicles. ed 1

Jena PK, Ramanjeneyulu K, Kumar KS, Bhat TB (2009) Ballistic studies on layered structures. Mater Des 30(6):1922–1929

Fei Z, Pan Z, Cuiuri D, Li H, Wu B, Ding D, Gazder AA (2018) Investigation into the viability of K-TIG for joining armour grade quenched and tempered steel. J Manuf Process 32:482–493

Kumbhar K, Senthil PP, Gogia AK (2017) Microstructural observations on the terminal penetration of long rod projectile. Def Technol 13(6):413–421

Pramanick AK, Das H, Reddy GM, Ghosh M, Das G, Nandy S, Pal TK (2016) Development and design of microstructure based coated electrode for ballistic performance of shielded metal arc welded armour steel joints. Mater Des 103:52–62

Kumar SN, Balasubramanian V, Malarvizhi S, Rahman AH, Balaguru V (2022) Effect of welding consumables on shielded metal arc welded ultra high hard armour steel joints. J Mech Behav Mater 31(1):8–21

Choudhary S, Singh PK, Khare S, Kumar K, Mahajan P, Verma RK (2020) Ballistic impact behaviour of newly developed armour grade steel: an experimental and numerical study. Int J Impact Eng 140:103557

Funding

The authors wish to record sincere thanks to the Directorate of Extramural Research & Intellectual Property Rights (ERIPR), Defence Research & Development Organisation (DRDO), Ministry of Defence, Government of India, New Delhi and Research Innovation Centre (RIC), DRDO, Chennai for the financial support rendered through an R&D Project No: EPIR/EP/RIC/2016/1/M/01/1630. The authors are grateful to the Director, Combat Vehicles Research & Development Establishment (CVRDE), DRDO, Avadi, Chennai for providing base materials to carry out this investigation. The authors wish to thank the Director, Defence Metallurgical Research Laboratory (DMRL), DRDO, Hyderabad for granting permission to conduct the ballistic test.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Naveen Kumar, S., Balasubramanian, V., Malarvizhi, S. et al. Experimental and Numerical Investigation on Ballistic Performance of Ultra High Hard Armour Steel Joints Welded Using Shielded Metal Arc Welding Process and Austenitic Stainless Steel Electrode. J. dynamic behavior mater. (2024). https://doi.org/10.1007/s40870-024-00421-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40870-024-00421-1