Abstract

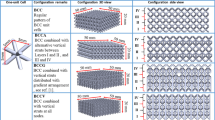

Architected cellular materials, such as lattice structures, offer potential for tunable mechanical properties for dynamic applications of energy absorption and impact mitigation. In this work, the static and dynamic behavior of polymeric lattice structures was investigated through experiments on octet-truss, Kelvin, and cubic topologies with relative densities around 8%. Dynamic testing was conducted via direct impact experiments (25–70 m/s) with high-speed imaging coupled with digital image correlation and a polycarbonate Hopkinson pressure bar. Mechanical properties such as elastic wave speed, deformation modes, failure properties, particle velocities, and stress histories were extracted from experimental results. At low impact velocities, a transient dynamic response was observed which was composed of a compaction front initiating at the impact surface and additional deformation bands whose characteristics matched low strain-rate behavior. For higher impact velocities, shock analysis was carried out using compaction wave velocity and Eulerian Rankine–Hugoniot jump conditions with parameters determined from full-field measurements.

Similar content being viewed by others

References

Gibson LJ, Ashby MF (1997) Cellular solids. Cambridge University Press, Cambridge. https://doi.org/10.1017/CBO9781139878326

Fleck NA, Deshpande VS, Ashby MF (2010) Micro-architectured materials: past, present and future. Proc R Soc A 466(2121):2495–2516. https://doi.org/10.1098/rspa.2010.0215

Ashby MF (2006) The properties of foams and lattices. Philos Trans R Soc A 364(1838):15–30. https://doi.org/10.1098/rsta.2005.1678

Zhang X, Wang Y, Ding B, Li X (2020) Design, fabrication, and mechanics of 3D micro-/nanolattices. Small 16(15):1–19. https://doi.org/10.1002/smll.201902842

Tofail SA, Koumoulos EP, Bandyopadhyay A, Bose S, O’Donoghue L, Charitidis C (2018) Additive manufacturing: scientific and technological challenges, market uptake and opportunities. Mater Today 21(1):22–37. https://doi.org/10.1016/j.mattod.2017.07.001

Helou M, Kara S (2018) Design, analysis and manufacturing of lattice structures: an overview. Int J Comput Integr Manuf 31(3):243–261. https://doi.org/10.1080/0951192X.2017.1407456

Tancogne-Dejean T, Li X, Diamantopoulou M, Roth CC, Mohr D (2019) High strain rate response of additively-manufactured plate-lattices: experiments and modeling. J Dyn Behav Mater 5(3):361–375. https://doi.org/10.1007/s40870-019-00219-6

Bonatti C, Mohr D (2019) Mechanical performance of additively-manufactured anisotropic and isotropic smooth shell-lattice materials: Simulations & experiments. J Mech Phys Solids 122:1–26. https://doi.org/10.1016/j.jmps.2018.08.022

Schaedler TA, Jacobsen AJ, Torrents A, Sorensen AE, Lian J, Greer JR, Valdevit L, Carter WB (2011) Ultralight metallic microlattices. Science 334(6058):962–965. https://doi.org/10.1126/science.1211649

Velasco-Hogan A, Xu J, Meyers MA (2018) Additive manufacturing as a method to design and optimize bioinspired structures. Adv Mater. https://doi.org/10.1002/adma.201800940

Xiao Z, Yang Y, Xiao R, Bai Y, Song C, Wang D (2018) Evaluation of topology-optimized lattice structures manufactured via selective laser melting. Mater Des 143:27–37. https://doi.org/10.1016/j.matdes.2018.01.023

Maconachie T, Leary M, Lozanovski B, Zhang X, Qian M, Faruque O, Brandt M (2019) SLM lattice structures: properties, performance, applications and challenges. Mater Design 183:108–137. https://doi.org/10.1016/j.matdes.2019.108137

Li X, Roth CC, Tancogne-Dejean T, Mohr D (2020) Rate- and temperature-dependent plasticity of additively manufactured stainless steel 316L: characterization, modeling and application to crushing of shell-lattices. Int J Impact Eng 145(July):103671. https://doi.org/10.1016/j.ijimpeng.2020.103671

Hazeli K, Babamiri BB, Indeck J, Minor A, Askari H (2019) Microstructure-topology relationship effects on the quasi-static and dynamic behavior of additively manufactured lattice structures. Mater Design 176:107826. https://doi.org/10.1016/j.matdes.2019.107826

Yap XY, Seetoh I, Goh WL, Ye P, Zhao Y, Du Z, Lai CQ (2021) Mechanical properties and failure behaviour of architected alumina microlattices fabricated by stereolithography 3D printing. Int J Mech Sci 196:106285. https://doi.org/10.1016/j.ijmecsci.2021.106285

Bauer J, Schroer A, Schwaiger R, Kraft O (2016) Approaching theoretical strength in glassy carbon nanolattices. Nat Mater 15(4):438–443. https://doi.org/10.1038/nmat4561

Montemayor LC, Wong WH, Zhang YW, Greer JR (2016) Insensitivity to flaws leads to damage tolerance in brittle architected meta-materials. Sci Rep 6(February):1–9. https://doi.org/10.1038/srep20570

Portela CM, Edwards BW, Veysset D, Sun Y, Nelson KA, Kochmann DM, Greer JR (2021) Supersonic impact resilience of nanoarchitected carbon. Nat Mater. https://doi.org/10.1038/s41563-021-01033-z

Zhang Y, Yu K, Lee KH, Li K, Du H (2022) Mechanics of stretchy elastomer lattices. J Mech Phys Solids 159:104782. https://doi.org/10.1016/j.jmps.2022.104782

Clough EC, Plaisted TA, Eckel ZC, Cante K, Hundley JM, Schaedler TA (2019) Elastomeric microlattice impact attenuators. Matter 1(6):1519–1531. https://doi.org/10.1016/j.matt.2019.10.004

Tancogne-Dejean T, Spierings AB, Mohr D (2016) Additively-manufactured metallic micro-lattice materials for high specific energy absorption under static and dynamic loading. Acta Mater 116:14–28. https://doi.org/10.1016/j.actamat.2016.05.054

Maxwell JC (1864) L on the calculation of the equilibrium and stiffness of frames. Lond Edinburgh Dublin Philos Mag J Sci 27(182):294–299. https://doi.org/10.1080/14786446408643668

Calladine CR (1978) Buckminster fuller’s “tensegrity’’ structures and clerk Maxwell’s rules for the construction of stiff frames. Int J Solids Struct 14(2):161–172. https://doi.org/10.1016/0020-7683(78)90052-5

Deshpande VS, Ashby MF, Fleck NA (2001) Foam topology: bending versus stretching dominated architectures. Acta Mater 49(6):1035–1040. https://doi.org/10.1016/S1359-6454(00)00379-7

Sun Y, Li QM (2018) Dynamic compressive behaviour of cellular materials: a review of phenomenon, mechanism and modelling. Int J Impact Eng 112:74–115. https://doi.org/10.1016/j.ijimpeng.2017.10.006

Xiao L, Song W (2018) Additively-manufactured functionally graded Ti–6Al–4V lattice structures with high strength under static and dynamic loading: experiments. Int J Impact Eng 111:255–272. https://doi.org/10.1016/j.ijimpeng.2017.09.018

Xiao L, Song W, Wang C, Tang H, Fan Q, Liu N, Wang J (2017) Mechanical properties of open-cell rhombic dodecahedron titanium alloy lattice structure manufactured using electron beam melting under dynamic loading. Int J Impact Eng 100:75–89. https://doi.org/10.1016/j.ijimpeng.2016.10.006

Weeks JS, Ravichandran G (2022) High strain-rate compression behavior of polymeric rod and plate Kelvin lattice structures. Mech Mater 166:104216. https://doi.org/10.1016/j.mechmat.2022.104216

Hawreliak JA, Lind J, Maddox B, Barham M, Messner MC, Barton NR, Jensen BJ, Kumar M (2016) Dynamic behavior of engineered lattice materials. Sci Rep 6(May):1–7. https://doi.org/10.1038/srep28094

Lind J, Jensen BJ, Barham MI, Kumar M (2019) In situ dynamic compression wave behavior in additively manufactured lattice materials. J Mater Res 34(1):2–19. https://doi.org/10.1557/jmr.2018.351

Branch BA, Specht PE, Jensen S, Jared B (2022) Detailed meso-scale simulations of the transient deformation in additively manufactured 316 L stainless steel lattices characterized by phase contrast imaging. Int J Impact Eng 161:104112. https://doi.org/10.1016/j.ijimpeng.2021.104112

Weeks JS, Gandhi V, Ravichandran G (2022) Shock compression behavior of stainless steel 316l octet-truss lattice structures. Int J Impact Eng 169:104324. https://doi.org/10.1016/j.ijimpeng.2022.104324

Reid S, Peng C (1997) Dynamic uniaxial crushing of wood. Int J Impact Eng 19(5):531–570. https://doi.org/10.1016/S0734-743X(97)00016-X

Liu YD, Yu JL, Zheng ZJ, Li JR (2009) A numerical study on the rate sensitivity of cellular metals. Int J Solids Struct 46(22–23):3988–3998. https://doi.org/10.1016/j.ijsolstr.2009.07.024

Zou Z, Reid SR, Tan PJ, Li S, Harrigan JJ (2009) Dynamic crushing of honeycombs and features of shock fronts. Int J Impact Eng 36(1):165–176. https://doi.org/10.1016/j.ijimpeng.2007.11.008

Tan PJ, Reid SR, Harrigan JJ, Zou Z, Li S (2005) Dynamic compressive strength properties of aluminium foams. Part I—Experimental data and observations. J Mech Phys Solids 53(10):2174–2205. https://doi.org/10.1016/j.jmps.2005.05.007

Tan PJ, Reid SR, Harrigan JJ, Zou Z, Li S (2005) Dynamic compressive strength properties of aluminium foams. Part II—‘shock’ theory and comparison with experimental data and numerical models. J Mech Phys Solids 53(10):2206–2230. https://doi.org/10.1016/j.jmps.2005.05.003

Barnes AT, Ravi-Chandar K, Kyriakides S, Gaitanaros S (2014) Dynamic crushing of aluminum foams: part I—experiments. Int J Solids Struct 51(9):1631–1645. https://doi.org/10.1016/j.ijsolstr.2013.11.019

Sun Y, Li QM, McDonald SA, Withers PJ (2016) Determination of the constitutive relation and critical condition for the shock compression of cellular solids. Mech Mater 99:26–36. https://doi.org/10.1016/j.mechmat.2016.04.004

Ramesh KT (2008) high strain rate and impact mechanics. Handbook of experimental solid mechanics. pp 929–960. https://doi.org/10.1007/978-0-387-30877-7_33

Meyers MA (1994) Dynamic behavior of materials. Wiley, Hoboken, pp 98–123. https://doi.org/10.1002/9780470172278

Winter RE, Cotton M, Harris EJ, Maw JR, Chapman DJ, Eakins DE, McShane GJ (2014) Plate-impact loading of cellular structures formed by selective laser melting. Modell Simul Mater Sci Eng. https://doi.org/10.1088/0965-0393/22/2/025021

Luo S, Jensen B, Hooks D, Fezzaa K, Ramos K, Yeager J, Kwiatkowski K, Shimada T (2012) Gas gun shock experiments with single-pulse X-ray phase contrast imaging and diffraction at the advanced photon source. Rev Sci Instrum 83(7):073903. https://doi.org/10.1063/1.4733704

Schreier H, Orteu JJ, Sutton MA et al (2009) Image correlation for shape, motion and deformation measurements: basic concepts, theory and applications, vol 1. Springer, New York. https://doi.org/10.1007/978-0-387-78747-3

Ravindran S, Koohbor B, Malchow P, Kidane A (2018) Experimental characterization of compaction wave propagation in cellular polymers. Int J Solids Struct 139–140:270–282. https://doi.org/10.1016/j.ijsolstr.2018.02.003

Köhnen P, Haase C, Bültmann J, Ziegler S, Schleifenbaum JH, Bleck W (2018) Mechanical properties and deformation behavior of additively manufactured lattice structures of stainless steel. Mater Des 145:205–217. https://doi.org/10.1016/j.matdes.2018.02.062

Deshpande V, Fleck N, Ashby M (2001) Effective properties of the octet-truss lattice material. J Mech Phys Solids 49(8):1747–1769. https://doi.org/10.1016/S0022-5096(01)00010-2

Callister WD, Rethwisch DG et al (2018) Material science and engineering: an introduction, vol 9. Wiley, New York

Bacon C (1998) An experimental method for considering dispersion and attenuation in a viscoelastic Hopkinson bar. Exp Mech 38(4):242–249. https://doi.org/10.1177/001448519803800402

Messner MC, Barham MI, Kumar M, Barton NR (2015) Wave propagation in equivalent continuums representing truss lattice materials. Int J Solids Struct 73:55–66. https://doi.org/10.1016/j.ijsolstr.2015.07.023

Messner MC (2016) Optimal lattice-structured materials. J Mech Phys Solids 96:162–183. https://doi.org/10.1016/j.jmps.2016.07.010

Davison L (2008) Fundamentals of shock wave propagation in solids. Shock wave and high pressure phenomena. Springer, Berlin. https://doi.org/10.1007/978-3-540-74569-3

Acknowledgements

The authors gratefully acknowledge the support of DOE/NNSA Award No. DE-NA0003957. The authors thank Prof. K.T. Faber (Caltech) for access to the Autodesk Ember 3D printer. The support of the Army Research Laboratory under the Cooperative Agreement Number W911NF-12-2-0022 for the acquisition of the high-speed camera used in this investigation is acknowledged. The views and conclusions contained in this document are those of the authors and should not be interpreted as representing the official policies, either expressed or implied, of the Army Research Laboratory or the U.S. Government. The U.S. Government is authorized to reproduce and distribute reprints for Government purposes notwithstanding any copyright notation herein.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Weeks, J.S., Ravichandran, G. Effect of Topology on Transient Dynamic and Shock Response of Polymeric Lattice Structures. J. dynamic behavior mater. 9, 44–64 (2023). https://doi.org/10.1007/s40870-022-00359-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40870-022-00359-2