Abstract

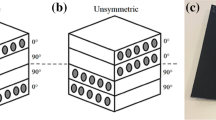

The impact performance of T650-35 stitched polyimide laminates and unstitched CFRP woven laminates is investigated at 23 and − 70 °C. Three impact energy levels of 6.7, 13.4, and 18.4 J/mm are selected to analyze the resulting damage modes. The results from the force–displacement and the absorbed energy curves evidently show that at − 70 °C, the specimens have noticeably higher initiation damage force for both material systems. Moreover, more significant load drops are observed at − 70 °C curves compared to the room temperature curves, which imply that multiple damage modes exist in greater extent at low temperature. The results further show that the T650-35 polyimide composites require higher impact load to initiate the matrix damage, indicating that the stitches efficiently suppressed the crack propagation on the samples. Furthermore, the T650-35 stitched polyimide composites can carry higher damage loads in both temperatures compared to the unstitched CFRP woven composites. X-ray micro-computed tomography technique is employed to reveal multiple complex impact damage modes. Results show that for unstitched composites impacted at 6.7 J/mm, − 70 °C samples experience multiple damage modes that include significant delamination, fiber breakage. However, for stitched composites impacted at 13.4 J/mm, similar complex damage modes are observed at 23 and − 70 °C.

Similar content being viewed by others

References

Abrate S (1998) Impact on composite structures. Cambridge University Press, Cambridge

Abrate S (1994) Impact on laminated composites: recent advances. Appl Mech Rev 47:517–544

Elamin M, Li B, Tan KT (2018) Impact damage of composite sandwich structures in arctic condition. Compos Struct 192:422–433

Reinhart TJ, Clements LL (1987) Introduction to composites engineered materials handbook, vol 1: Composites. In: Dostal Cyril A et al (eds). ASM International, Geauga County, OH

Feng D, Aymerich F (2014) Finite element modelling of damage induced by low-velocity impact on composite laminates. Compos Struct 108:161–171

Zhou G, Davies G (1995) Impact response of thick glass fibre reinforced polyester laminates. Int J Impact Eng 16(3):357–374

Zhou G (1998) The use of experimentally-determined impact force as a damage measure in impact damage resistance and tolerance of composite structures. Compos Struct 42(4):375–382

Cox BN (1999) Constitutive model for a fiber tow bridging a delamination crack. Mech Compos Mater Struct 6:117–138

Cox BN, Massabo R, Kedward KT (1996) Suppression of delaminations in curved structures by stitching. Compos Part A 127A:1133–1138

Tada Y, Ishikawa T (1989) Experimental evaluation of the effects of stitching on CFRP laminate specimens with various shapes and locations. Key Eng Mater 37:305–316

Mouritz AP, Jain LK (1999) Further validation of the Jain and Mai models for interlaminar fracture of stitched composites. Compos Sci Technol 59:1653–1662

Tan KT, Watanabe N, Iwahori Y, Hoshi H, Sano M (2010) Interlaminar fracture toughness of Vectran-stitched composites-experimental and computational analysis. J Compos Mater 44(26):3203–3229

Iwahori Y, Nakane K, Watanabe N (2009) DCB test simulation of stitched CFRP laminates using interlaminar tension test results. Compos Sci Technol 69:2315–2322

Jain LK, Mai YW (1995) Determination of mode II delamination toughness of stitched laminated composites. Compos Sci Technol 155:241–253

Jain LK, Dransfield KA, Mai YW (1998) On the effects of stitching in CFRPs – II. Mode II delamination toughness. Compos Sci Technol 58:829–837

Mouritz AP (2001) Ballistic impact and explosive blast resistance of stitched composites. Compos Part B 32:431–439

Caprino G, Lopresto V, Santoro D (2007) Ballistic impact behaviour of stitched graphite/epoxy laminates. Compos Sci Technol 67:325–335

Sankar BV, Zhu HS (2000) The effect of stitching on the low-velocity impact response of delaminated composite beams. Compos Sci Technol 60:2681–2691

Mouritz AP, Gallagher J, Goodwin AA (1997) Flexural strength and interlaminar shear strength of stitched GRP laminates following repeated impacts. Compos Sci Technol 57:509–522

Lopresto V, Melito V, Leone C, Caprino G (2006) Effect of stitches on the impact behaviour of graphite/epoxy composites. Compos Sci Technol 66:206–214

Yoshimura A, Nakao T, Yashiro S, Takeda N (2008) Improvement on out-of-plane impact resistance of CFRP laminates due to through-the-thickness stitching. Compos Part A 39:1370–1379

Larsson F (1997) Damage tolerance of a stitched carbon/epoxy laminate. Compos Part A 28A:923–934

Zhao NP, Rodel H, Herzberg C, Gao SL, Krzywinski S (2009) Stitched glass/PP composite. Part I: tensile and impact properties. Compos Part A 40:635–643

Byun JH, Song SW, Lee CH, Um MK, Hwang BS (2006) Impact properties of laminated composites with stitching fibers. Compos Struct 76:21–27

Kang TJ, Lee SH (1994) Effect of stitching on the mechanical and impact properties of woven laminate composite. J Compos Mater 28(16):1574–1587

Hosur MV, Vaidya UK, Ulven C, Jeelani S (2004) Performance of stitched/unstitched woven carbon/epoxy composites under high velocity impact loading. Compos Struct 64:455–466

Tan KT, Watanabe N, Iwahori Y (2010) Effect of stitch density and stitch thread thickness on low-velocity impact damage of stitched composites. Compos Part A 41:1857–1868

Vihma T (2014) Effects of arctic sea ice decline on weather and climate: a review. Surv Geophys 35(5):1175

Schutz JB (1998) Properties of composite materials for cryogenic applications. Cryogenics 38:3–12

Timmerman JF, Tillman MS, Hayes BS, Seferis JC (2001) Matrix and fiber influences on the cryogenic microcracking of carbon fiber/epoxy composites. Compos Part A 33:323–329

Sanchez-Saez S, Gomez-del Rıo T, Barbero E, Zaera R, Navarro C (2002) Static behavior of CFRPs at low temperatures. Compos Part B 33:383–390

Im KH, Cha CS, Kim SK, Yang IY (2001) Effects of temperature on impact damages in CFRP composite laminates. Compos Part B 32(8):669–682

López-Puente J, Zaera R, Navarro C (2002) The effect of low temperatures on the intermediate and high velocity impact response of CFRPs. Compos Part B 33(8):559–566

Gómez-del Rıo T, Zaera R, Barbero E, Navarro C (2005) Damage in CFRPs due to low velocity impact at low temperature. Compos Part B 36(1):41–50

ASTM D7136/D7136M (2014) Standard testing method for measuring the damage resistance of a fiber-reinforced polymer matrix composite to a drop-weight impact event. ASTM International, West Conshohocken, PA

Tan KT, Watanabe N, Iwahori Y (2011) X-ray radiography and micro-computed tomography examination of damage characteristics in stitched composites subjected to impact loading. Compos Part B 42(4):874–884

Chu XX, Wu ZX, Huang RJ, Zhou Y, Li LF (2010) Mechanical and thermal expansion properties of glass fibers reinforced PEEK composites at cryogenic temperatures. Cryogenics 50(2):84–88

Sánchez-Sáez S, Barbero E, Navarro C (2008) Compressive residual strength at low temperatures of composite laminates subjected to low-velocity impacts. Compos Struct 85(3):226–232

Acknowledgements

The authors acknowledge the research Grant N00014-16-1-3202 provided by the Office of Naval Research (ONR Program Manager: Dr. Yapa Rajapakse). The authors also thank Dr. Kathy Chuang (NASA Glenn Research Center) for providing the stitched composite specimens.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Elamin, M., Li, B. & Tan, K.T. Impact Performance of Stitched and Unstitched Composites in Extreme Low Temperature Arctic Conditions. J. dynamic behavior mater. 4, 317–327 (2018). https://doi.org/10.1007/s40870-018-0158-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40870-018-0158-2