Abstract

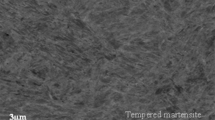

In the present study, the dynamic response of a high-strength, low alloy Grade 65 (HSLA-65) steel, used by the United States Navy for ship hull construction, is investigated under dynamic uniaxial compression at temperatures ranging from room temperature to 1000 °C using a novel elevated temperature split-Hopkinson pressure bar. These experiments are designed to probe the dynamic response of HSLA-65 steel in its single α-ferrite phase, mixed α + γ-austenite phase, and the single γ-austenite phase, as a function of temperature. The investigation is conducted at two different average strain rates—1450 and 2100/s. The experimental results indicate that at test temperatures in the range from room temperature to lower than 600 °C, i.e. prior to the development of the mixed α + γ phase, a net softening in flow strength is observed at all levels of plastic strain with increase in test temperatures. As the test temperatures are increased, the rate of this strain softening with temperature is observed to decrease, and at 600 °C the trend reverses itself resulting in an increase in flow stress at all strains tested. This increase in flow stress is understood be due to dynamic strain aging, where solute atoms play a distinctive role in hindering dislocation motion. At 800 °C, a (sharp) drop in the flow stress, equivalent to one-half of its value at room temperature, is observed. As the test temperature are increased to 900 and 1000 °C, further drop in flow stress are observed at all plastic strain levels. In addition, strain hardening in flow stress is observed at all test temperatures up to 600 °C; beyond 800 °C the rate of strain hardening is observed to decrease, with strain softening becoming dominant at temperatures of 900 °C and higher. Moreover, comparing the high strain rate stress versus strain data gathered on HSLA 65 in the current investigation with those available in the literature at quasi-static strain rates, strain-rate hardening can be inferred. The flow stress increases from 700 MPa at 8 × 10−4/s to 950 MPa at 1450/s and then to 1000 MPa at 2100/s at a strain of 0.1. Optical microscopy is used to understand evolution of microstructure in the post-test samples at the various test temperatures employed in the present study.

Similar content being viewed by others

References

Konkol P, Warren J, Hebert P (1998) Weldability of HSLA-65 steel for ship structures. Weld Res Suppl 77:s361–s371

Posada M, Nguyen JP, Forrest DR, DeLoach JJ, DeNale R (2003) Friction stir welding advances joining technology. AMPTIAC Q 7(3):13–20

Norton SJ (2006) Ferrous friction stir weld physical simulation. Doctor of Philosophy, Ohio State University

Zener C, Hollomon JH (1944) Effect of strain rate upon plastic flow of steel. J Appl Phys 15(1):22–32

Hwang KC, Lee S, Lee HC (1998) Effects of alloying elements on microstructure and fracture properties of cast high speed steel rolls: part II. Fracture behavior. Mater Sci Eng A 254(1):296–304

Kim CK, Kim YC, Park JI, Lee S, Kim NJ, Yang JS (2005) Effects of alloying elements on microstructure, hardness, and fracture toughness of centrifugally cast high-speed steel rolls. Metall Mater Trans A 36(1):87–97

Rusinek A, Klepaczko J (2001) Shear testing of a sheet steel at wide range of strain rates and a constitutive relation with strain-rate and temperature dependence of the flow stress. Int J Plast 17(1):87–115

Campbell J, Ferguson W (1970) The temperature and strain-rate dependence of the shear strength of mild steel. Philos Mag 21(169):63–82

Liang R, Khan AS (1999) A critical review of experimental results and constitutive models for BCC and FCC metals over a wide range of strain rates and temperatures. Int J Plast 15(9):963–980

Khan AS, Liang R (1999) Behaviors of three BCC metal over a wide range of strain rates and temperatures: experiments and modeling. Int J Plast 15(10):1089–1109

ASTM A945/A945M-16 (2016) Standard specification for high-strength low-alloy structural steel plate with low carbon and restricted sulfur for improved weldability, formability, and toughness. ASTM International, West Conshohocken

Ballance J (1976) The hot deformation of austenite. AIME, New York

Gokyu I, Kihara J (1966) Plasticity of body-centered cubic metals at high strain rate. Trans Iron Steel Inst Jpn 6(4):38–45

Saito Y (1987) Mathematical model of hot deformation resistance in austenite-ferrite two phase region. Trans Iron Steel Inst Jpn 27(6):419–424

Nemat-Nasser S, Guo W-G (2005) Thermomechanical response of HSLA-65 steel plates: experiments and modeling. Mech Mater 37(2–3):379–405

Krauss G (1990) Microstructures, processing, and properties of steels. ASM handbook. ASM World Headquarters, Materials Park

Sunny GP, Lewandowski JJ, Prakash V (2007) Effects of annealing and specimen geometry on dynamic compression of a zirconium-based bulk metallic glass. J Mater Res 22(2):389–401

Shazly M, Prakash V, Lerch BA (2009) High strain-rate behavior of ice under uniaxial compression. Int J Solids Struct 46(6):1499–1515

Shazly M, Prakash V, Draper S (2004) Mechanical behavior of Gamma-Met PX under uniaxial loading at elevated temperatures and high strain rates. Int J Solids Struct 41(22):6485–6503

Sunny G, Yuan F, Prakash V, Lewandowski JJ (2009) Design of inserts for split-Hopkinson pressure bar testing of low strain-to-failure materials. Exp Mech 49(4):479–490

Yuan F, Prakash V, Tullis T (2011) Origin of pulverized rocks during earthquake fault rupture. J Geophys Res. doi:10.1029/2010JB007721

Shazly M, Prakash V, Lerch B (2006) High strain-rate compression testing of ice. NASA Glenn Research Center, Cleveland

Irfan MA, Prakash V (2000) Dynamic deformation and fracture behavior of novel damage tolerant discontinuously reinforced aluminum composites. Int J Solids Struct 37:4477–4507

Sunny G, Yuan F, Prakash V, Lewandowski JJ (2008) Effect of high strain rates on peak stress in a Zr-based bulk metallic glass. J Appl Phys 104:093522

Prakash V, Mehta N (2012) Uniaxial compression and combined compression-and-shear response of amorphous polycarbonate at high loading rates. Polym Eng Sci 52(6):1217–1231

Wu X, Prakash V (2015) Dynamic compressive behavior of ice at cryogenic temperatures. Cold Reg Sci Technol 118:1–18

Wu X, Prakash V (2015) Dynamic strength of distill water and lake water ice at high strain rates. Int J Impact Eng 76:155–165

Mecking H, Kocks U (1981) Kinetics of flow and strain-hardening. Acta Metall 29(11):1865–1875

Cho S-H, Yoo Y-C, Jonas J (2000) Static and dynamic strain aging in 304 austenitic stainless steel at elevated temperatures. J Mater Sci Lett 19(22):2019–2022

Robbins JL, Wagenaar H, Shepard OC, Sherby OD (1967) Torsion testing as a means of assessing ductility at high temperatures. J Met 2(2):271–299

Robbins JL, Shepard OC, Sherby OD (1967) Torsional ductility and strength of iron-carbon alloys at elevated temperatures. Trans ASM 60:205–216

Acknowledgements

The authors would like to the Office of Naval Research through Grant (ONR-N00014-07-0527) and the U.S. Department of Energy through the Stewardship Science Academic Alliance (DE-NA0001989 and DE-NA0002919) for conducting the present research. The authors would like to additionally thank Dr. Murray Mahoney for the supply of HSLA-65 steel used in the current investigation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dike, S., Wang, T., Zuanetti, B. et al. Dynamic Uniaxial Compression of HSLA-65 Steel at Elevated Temperatures. J. dynamic behavior mater. 3, 510–525 (2017). https://doi.org/10.1007/s40870-017-0130-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40870-017-0130-6