Abstract

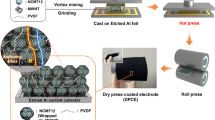

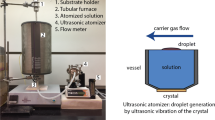

The solvent-free dry process for fabricating battery electrodes has received widespread attention owing to its low cost and environmental friendliness. However, the conventional polytetrafluoroethylene (PTFE) used as a binder in the preparation of dry-processed electrodes results in insufficient adhesion, limiting their practical industrial applications. Herein, we reported an industrially viable dry process for producing lithium-ion batteries using the combination of carboxymethyl cellulose (CMC) and siloxane as the binder composite. The synergistic effect of CMC and siloxane enhanced the adhesive performance of the electrode, thereby improving the mechanical strength and electrochemical performance of the developed dry-processed electrode. Half cells based on aluminum-doped lithium manganese oxide (LMA) dry-processed electrodes with CMC and siloxane (LMA/CS) exhibited a capacity retention of 79.8% after 200 cycles at 1 C. Furthermore, LMA/CS∥lithium titanate oxide full cells with a high mass loading of 20.6 mg cm−2 demonstrated an excellent capacity retention of 89.2% after 1000 cycles, which is considerably higher than that of cells based on slurry-processed electrodes prepared with a polyvinylidene fluoride binder and conventional dry-processed electrodes prepared using a PTFE binder.

摘要

近年来, 无溶剂干法电极制备工艺由于其低成本和低污染等优 点在锂电池领域获得了广泛关注. 然而, 现有干法制备工艺中采用的聚 四氟乙烯(PTFE)粘结剂存在粘附力和循环稳定性不足等缺点, 限制了 其实际工业化应用. 我们通过引入羧甲基纤维素(CMC)和硅氧烷作为 粘结剂复合材料, 发展了一种与现有工业化生产兼容的锂离子电池干 法电极制备工艺. CMC和硅氧烷的协同作用增强了电极活性材料的粘 附性能, 实现了干法电极膜片机械强度和电化学性能的大幅提升. 基于 这种干法电极工艺制备的铝掺杂锰酸锂(LMA/CS)半电池在1 C下循环 200圈后展示出79.8%的保持率. 进一步地, 制备的高负载(20.6 mg cm−2) 锰酸锂-钛酸锂全电池(LMA/CS∥LTO)实现了1000圈的超长稳定循环, 容量保持率高达89.2%, 超过现有基于PTFE粘结剂干法工艺和传统湿 法工艺的电池性能.

Similar content being viewed by others

References

Quilty CD, Wu D, Li W, et al. Electron and ion transport in lithium and lithium-ion battery negative and positive composite electrodes. Chem Rev, 2023, 123: 1327–1363

Lu Y, Rong X, Hu YS, et al. Research and development of advanced battery materials in China. Energy Storage Mater, 2019, 23: 144–153

Zhou G, Li F, Cheng HM. Progress in flexible lithium batteries and future prospects. Energy Environ Sci, 2014, 7: 1307–1338

Zhong W, Zhang C, Li S, et al. Mo2C catalyzed low-voltage prelithiation using nano-Li2C2O4 for high-energy lithium-ion batteries. Sci China Mater, 2022, 66: 903–912

Xu L, Sun Z, Zhu Y, et al. A Li-rich layered-spinel cathode material for high capacity and high rate lithium-ion batteries fabricated via a gas-solid reaction. Sci China Mater, 2020, 63: 2435–2442

Ryu M, Hong YK, Lee SY, et al. Ultrahigh loading dry-process for solvent-free lithium-ion battery electrode fabrication. Nat Commun, 2023, 14: 1316

Zhang Z, Sun S, Zhang W, et al. Internally inflated core-buffer-shell structural Si/EG/C composites as high-performance anodes for lithium-ion batteries. Sci China Mater, 2022, 65: 2949–2957

Pettinger KH, Dong W. When does the operation of a battery become environmentally positive? J Electrochem Soc, 2017, 164: A6274–A6277

Liu Y, Zhang R, Wang J, et al. Current and future lithium-ion battery manufacturing. iScience, 2021, 24: 102332

Degen F, Winter M, Bendig D, et al. Energy consumption of current and future production of lithium-ion and post lithium-ion battery cells. Nat Energy, 2023, 8: 1284–1295

Agarwal RG, Coste SC, Groff BD, et al. Free energies of proton-coupled electron transfer reagents and their applications. Chem Rev, 2021, 122: 1–49

Yao W, Chouchane M, Li W, et al. A 5 V-class cobalt-free battery cathode with high loading enabled by dry coating. Energy Environ Sci, 2023, 16: 1620–1630

Lingappan N, Kong L, Pecht M. The significance of aqueous binders in lithium-ion batteries. Renew Sustain Energy Rev, 2021, 147: 111227

Zhang Z, Zeng T, Qu C, et al. Cycle performance improvement of LiFePO4 cathode with polyacrylic acid as binder. Electrochim Acta, 2012, 80: 440–444

Li Y, Wu Y, Wang Z, et al. Progress in solvent-free dry-film technology for batteries and supercapacitors. Mater Today, 2022, 55: 92–109

Liu Y, Gong X, Podder C, et al. Roll-to-roll solvent-free manufactured electrodes for fast-charging batteries. Joule, 2023, 7: 952–970

Kato Y, Shiotani S, Morita K, et al. All-solid-state batteries with thick electrode configurations. J Phys Chem Lett, 2018, 9: 607–613

Abdollahifar M, Cavers H, Scheffler S, et al. Insights into influencing electrode calendering on the battery performance. Adv Energy Mater, 2023, 13: 2300973

Tao R, Steinhoff B, Sun XG, et al. High-throughput and high-performance lithium-ion batteries via dry processing. Chem Eng J, 2023, 471: 144300

Wang C, Yu R, Duan H, et al. Solvent-free approach for interweaving freestanding and ultrathin inorganic solid electrolyte membranes. ACS Energy Lett, 2021, 7: 410–416

Hong SB, Lee YJ, Kim UH, et al. All-solid-state lithium batteries: Li+-conducting ionomer binder for dry-processed composite cathodes. ACS Energy Lett, 2022, 7: 1092–1100

Tao R, Tan S, Meyer III HM, et al. Insights into the chemistry of the cathodic electrolyte interphase for PTFE-based dry-processed cathodes. ACS Appl Mater Interfaces, 2023, 15: 40488–40495

Nirmale TC, Kale BB, Varma AJ. A review on cellulose and lignin based binders and electrodes: Small steps towards a sustainable lithium ion battery. Int J Biol Macromolecules, 2017, 103: 1032–1043

Teng X, Fang W, Liang Y, et al. High-performance polyamide nano-filtration membrane with arch-bridge structure on a highly hydrated cellulose nanofiber support. Sci China Mater, 2020, 63: 2570–2581

Liang Y, Wei Z, Wang H-E, et al. Flexible freestanding conductive nanopaper based on PPy:PSS nanocellulose composite for super-capacitors with high performance. Sci China Mater, 2022, 66: 964–973

Lux SF, Schappacher F, Balducci A, et al. Low cost, environmentally benign binders for lithium-ion batteries. J Electrochem Soc, 2010, 157: A320

Buqa H, Holzapfel M, Krumeich F, et al. Study of styrene butadiene rubber and sodium methyl cellulose as binder for negative electrodes in lithium-ion batteries. J Power Sources, 2006, 161: 617–622

Ma C, Wen Y, Qiao Q, et al. Improving electrochemical performance of high-voltage spinel LiNi0.5Mn1.5O4 cathodes by silicon oxide surface modification. ACS Appl Energy Mater, 2021, 4: 12201–12210

Meng J, Chu F, Hu J, et al. Liquid polydimethylsiloxane grafting to enable dendrite-free Li plating for highly reversible Li-metal batteries. Adv Funct Mater, 2019, 29: 1902220

Oh I, Cho J, Kim K, et al. Poly(imide-co-siloxane) as a thermo-stable binder for a thin layer cathode of thermal batteries. Energies, 2018, 11: 3154

Wang H, Zhang X, Li Y, et al. Siloxane-based organosilicon materials in electrochemical energy storage devices. Angew Chem Int Ed, 2022, 61: e202210851

Kim HJ, Kim JS, Song SW. Uniform distribution of siloxane-grafted SiO nanoparticles in micron hard-carbon matrix for high-rate composite anode in Li-ion batteries. J Solid State Chem, 2019, 270: 479–486

Teng P, Wang Z, Kang Y, et al. Metal-ion-tunable adhesive elastomers for mounting the multilayer elastic circuit. Sci China Mater, 2023, 66: 4054–4061

Hippauf F, Schumm B, Doerfler S, et al. Overcoming binder limitations of sheet-type solid-state cathodes using a solvent-free dry-film approach Energy. Storage Mater, 2019, 21: 390–398

Kim SW, Kim T, Kim YS, et al. Surface modifications for the effective dispersion of carbon nanotubes in solvents and polymers. Carbon, 2012, 50: 3–33

Wang Y, Dong N, Liu B, et al. Self-adaptive gel poly(imide-siloxane) binder ensuring stable cathode-electrolyte interface for achieving high-performance NCM811 cathode in lithium-ion batteries. Energy Storage Mater, 2023, 56: 621–630

Li Z, Wu G, Yang Y, et al. An ion-conductive grafted polymeric binder with practical loading for silicon anode with high interfacial stability in lithium-ion batteries. Adv Energy Mater, 2022, 12: 2201197

Yao Q, Zhu Y, Zheng C, et al. Intermolecular cross-linking reinforces polymer binders for durable alloy-type anode materials of sodium-ion batteries. Adv Energy Mater, 2022, 13: 2202939

Deng S, Wang H, Liu H, et al. Research progress in improving the rate performance of LiFePO4 cathode materials. Nano-Micro Lett, 2014, 6: 209–226

Al-Shroofy M, Zhang Q, Xu J, et al. Solvent-free dry powder coating process for low-cost manufacturing of LiNi1/3Mn1/3Co1/3O2 cathodes in lithium-ion batteries. J Power Sources, 2017, 352: 187–193

Daemi SR, Tan C, Volkenandt T, et al. Visualizing the carbon binder phase of battery electrodes in three dimensions. ACS Appl Energy Mater, 2018, 1: 3702–3710

Font F, Protas B, Richardson G, et al. Binder migration during drying of lithium-ion battery electrodes: Modelling and comparison to experiment. J Power Sources, 2018, 393: 177–185

Ahn J, Im HG, Lee Y, et al. A novel organosilicon-type binder for LiCoO2 cathode in Li-ion batteries. Energy Storage Mater, 2022, 49: 58–66

Acknowledgements

This work was supported by the National Natural Science Foundation of China (52090034), the Ministry of Science and Technology of China (2020YFA0711500), and the Higher Education Discipline Innovation Project (111 Project B12015).

Author information

Authors and Affiliations

Contributions

Author contributions Zhang H conceived and designed the research; Ni M fabricated the electrodes and assembled the cells; Ni M, Zhao Y and Xu N conducted the characterizations and analyses with support from Kong M, Ma Y and Li C; Ni M and Zhang H wrote the paper with support from Chen Y; Chen Y and Zhang H coordinated the study. All authors contributed to the general discussion.

Corresponding author

Ethics declarations

Conflict of interest The authors declare that they have no conflict of interest.

Additional information

Supplementary information Experimental details and supporting data are available in the online version of the paper.

Minghan Ni received her BS degree in materials science and engineering from China University of Geoscience (Beijing). Currently, she is pursuing her Master’s degree at Nankai University under the guidance of Prof. Yongsheng Chen. Her research is primarily focused on improving the electrochemical performances and mechanical properties of dry-processed LIBs.

Hongtao Zhang received his PhD degree from the Institute of Chemistry, Chinese Academy of Sciences in 2012. He joined Prof. Yongsheng Chen’s group at Nankai University in 2014. He worked as a visiting scholar at the University of California, Los Angeles from 2018 to 2019. His current research primarily centers on polymer solid electrolytes and high-performance lithium metal batteries.

Yongsheng Chen graduated from the University of Victoria with a PhD degree in chemistry in 1997 and then joined the University of Kentucky and the University of California, Los Angeles for postdoctoral reseach from 1997 to 1999. Since 2003, he has been a chair professor at Nankai University. His main research interests include (i) carbon-based nanomaterials, including carbon nanotubes and grapheme, (ii) organic and polymeric functional materials, and (iii) energy devices including organic photovoltaics and supercapacitors.

Electronic supplementary material

40843_2023_2673_MOESM1_ESM.pdf

Improving the cycling stability of lithium-ion batteries with a dry-processed cathode via the synergistic effect of carboxymethyl cellulose and siloxane

Rights and permissions

About this article

Cite this article

Ni, M., Zhao, Y., Xu, N. et al. Improving the cycling stability of lithium-ion batteries with a dry-processed cathode via the synergistic effect of carboxymethyl cellulose and siloxane. Sci. China Mater. 67, 76–84 (2024). https://doi.org/10.1007/s40843-023-2673-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40843-023-2673-6