Abstract

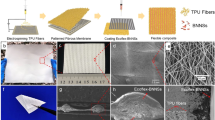

Soft wearable cooling devices using flexible thermoelectric coolers (TECs) are highly advantageous for diverse applications. However, challenges remain in low cooling capacity, short device lifetime, and limited understandings of the impact of thermoelectric component’s dimension, structure and density on their cooling capacity. Here, we addressed these issues by engineering a large-electrode flexible TEC composed of thermoelectric components embedded in a three-layer polydimethylsiloxane (PDMS) matrix interconnected with biphasic liquid metal traces (core-shell structured liquid metal nanoparticles and nickel-doped GaIn). Attributed to the larger electrodes and three-layer PDMS, the TECs significantly reduce the amount of liquid metal used, minimize the risk of leakage, lower the cost, eliminate environmental pollution, and improve product reliability and manufacturing efficiency. We further optimized the TEC structure design by finite element analysis, providing a generic TEC design kit taking into account multiple physical fields and impact factors. The demonstrated TECs offer high cooling capacity (7.4°C) and great performance stability under deformation, which outperform previously reported models that use similar materials and structures. This work represents a significant step forward in the development of flexible TECs, with promising applications in fields such as wearable devices, electronic skins, and smart textiles.

摘要

为了提高柔性热电冷却器(TEC)的冷却能力, 解决液态金属材料的泄漏问题, 同时研究热电腿的尺寸、 密度和形状对TEC冷却能力的影响. 本文将具有液态核心氧化壳结构的Ni-GaIn(掺镍液态金属)和LMPs(液态金属纳米颗粒)引入柔性TEC中, 并针对材料的特性, 采用“较大的电极”和“三层PDMS”对传统的热电冷却结构进行了改进. 采用“大电极”和“三层PDMS”解决了液态金属量大、 易泄漏的问题, 降低了成本和环境污染, 提高了产品可靠性和制造效率. 利用有限元分析软件对结构进行了进一步优化, 提供了多物理场和多因素影响下的TEC设计方案. 与已报道的采用EGaIn互连和传统热电冷却结构的柔性TEC相比, 本文制备的两种新型柔性TEC分别具有冷却能力高(7.4°C)和性能稳定(受弯曲变形影响小)的特点.

Similar content being viewed by others

References

Goldstein LS, Dewhirst MW, Repacholi M, et al. Summary, conclusions and recommendations: adverse temperature levels in the human body. Int J Hyperthermia, 2003, 19: 373–384

Stockholm JG. Current state of Peltier cooling. In: 16th International Conference on Thermoelectrics. Dresden, 1997. 37–46

He W, Zhang G, Zhang X, et al. Recent development and application of thermoelectric generator and cooler. Appl Energy, 2015, 143: 1–25

Pourkiaei SM, Ahmadi MH, Sadeghzadeh M, et al. Thermoelectric cooler and thermoelectric generator devices: A review of present and potential applications, modeling and materials. Energy, 2019, 186: 115849

Wang R, Zhou X, Wang W, et al. Twist-based cooling of polyvinylidene difluoride for mechanothermochromic fibers. Chem Eng J, 2021, 417: 128060

Zaferani SH, Sams MW, Ghomashchi R, et al. Thermoelectric coolers as thermal management systems for medical applications: Design, optimization, and advancement. Nano Energy, 2021, 90: 106572

Wang R, Fang S, Xiao Y, et al. Torsional refrigeration by twisted, coiled, and supercoiled fibers. Science, 2019, 366: 216–221

Si Y, Shi S, Dong Z, et al. Bioinspired stable single-layer Janus fabric with directional water/moisture transport property for integrated personal cooling management. Adv Fiber Mater, 2023, 5: 138–153

Du Y, Xu J, Paul B, et al. Flexible thermoelectric materials and devices. Appl Mater Today, 2018, 12: 366–388

Hong S, Gu Y, Seo JK, et al. Wearable thermoelectrics for personalized thermoregulation. Sci Adv, 2019, 5: eaaw0536

Dezellus O, Eustathopoulos N. Fundamental issues of reactive wetting by liquid metals. J Mater Sci, 2010, 45: 4256–4264

Handschuh-Wang S, Zhu L, Gan T, et al. Interfacing of surfaces with gallium-based liquid metals—Approaches for mitigation and augmentation of liquid metal adhesion on surfaces. Appl Mater Today, 2020, 21: 100868

Deng YG, Liu J. Corrosion development between liquid gallium and four typical metal substrates used in chip cooling device. Appl Phys A, 2009, 95: 907–915

Suarez F, Parekh DP, Ladd C, et al. Flexible thermoelectric generator using bulk legs and liquid metal interconnects for wearable electronics. Appl Energy, 2017, 202: 736–745

Won P, Jeong S, Majidi C, et al. Recent advances in liquid-metal-based wearable electronics and materials. iScience, 2021, 24: 102698

Ozutemiz KB, Wissman J, Ozdoganlar OB, et al. EGaIn-metal interfacing for liquid metal circuitry and microelectronics integration. Adv Mater Interfaces, 2018, 5: 1701596

Sun X, Sun M, Liu M, et al. Shape tunable gallium nanorods mediated tumor enhanced ablation through near-infrared photothermal therapy. Nanoscale, 2019, 11: 2655–2667

Chiechi RC, Weiss EA, Dickey MD, et al. Eutectic gallium-indium (EGaIn): A moldable liquid metal for electrical characterization of self-assembled monolayers. Angew Chem, 2008, 120: 148–150

Nimmagadda LA, Mahmud R, Sinha S. Materials and devices for on-chip and off-chip peltier cooling: A review. IEEE Trans Compon Packag Manufact Technol, 2021, 11: 1267–1281

Gong T, Gao L, Wu Y, et al. Numerical simulation on a compact thermoelectric cooler for the optimized design. Appl Therm Eng, 2019, 146: 815–825

Lee D, Park H, Park G, et al. Liquid-metal-electrode-based compact, flexible, and high-power thermoelectric device. Energy, 2019, 188: 116019

Bang KM, Park W, Ziolkowski P, et al. Fabrication and cooling performance optimization of stretchable thermoelectric cooling device. ACS Appl Electron Mater, 2021, 3: 5433–5442

Mitrani D, Tome JA, Salazar J, et al. Methodology for extracting thermoelectric module parameters. IEEE Trans Instrum Meas, 2005, 54: 1548–1552

Poh C, Chen S, Wang T, et al. Analysis of characteristics and performance of thermoelectric modules. In: 2016 5th International Symposium on Next-Generation Electronics (ISNE). Hsinchu, 2016. 1–2

Lee G, Kim CS, Kim S, et al. Flexible heatsink based on a phase-change material for a wearable thermoelectric generator. Energy, 2019, 179: 12–18

Jeong ES. Optimization of thermoelectric modules for maximum cooling capacity. Cryogenics, 2021, 114: 103241

Kishore RA, Nozariasbmarz A, Poudel B, et al. Ultra-high performance wearable thermoelectric coolers with less materials. Nat Commun, 2019, 10: 1765

Erturun U, Erermis K, Mossi K. Effect of various leg geometries on thermo-mechanical and power generation performance of thermoelectric devices. Appl Therm Eng, 2014, 73: 128–141

Guo R, Sun X, Yao S, et al. Semi-liquid-metal-(Ni-EGaIn)-based ultraconformable electronic tattoo. Adv Mater Technologies, 2019, 4: 1900183

Lee J, Jung S, Kim W. Dependence of the effective surface tension of liquid phase eutectic gallium indium on wrinkles of the surface oxide. Extreme Mech Lett, 2021, 48: 101386

Ding Y, Zeng M, Fu L. Surface chemistry of gallium-based liquid metals. Matter, 2020, 3: 1477–1506

Zheng Y, He ZZ, Yang J, et al. Personal electronics printing via tapping mode composite liquid metal ink delivery and adhesion mechanism. Sci Rep, 2014, 4: 4588

Guo R, Wang H, Sun X, et al. Semiliquid metal enabled highly conductive wearable electronics for smart fabrics. ACS Appl Mater Interfaces, 2019, 11: 30019–30027

Creighton MA, Yuen MC, Susner MA, et al. Oxidation of gallium-based liquid metal alloys by water. Langmuir, 2020, 36: 12933–12941

Zhang M, Yao S, Rao W, et al. Transformable soft liquid metal micro/nanomaterials. Mater Sci Eng-R-Rep, 2019, 138: 1–35

Ren L, Zhuang J, Casillas G, et al. Nanodroplets for stretchable superconducting circuits. Adv Funct Mater, 2016, 26: 8111–8118

Scharmann F, Cherkashinin G, Breternitz V, et al. Viscosity effect on GaInSn studied by XPS. Surf Interface Anal, 2004, 36: 981–985

Yuan Y, Hao W, Mu W, et al. Toward emerging gallium oxide semiconductors: A roadmap. Fundamental Res, 2021, 1: 697–716

Khoshmanesh K, Tang SY, Zhu JY, et al. Liquid metal enabled microfluidics. Lab Chip, 2017, 17: 974–993

Kim S, Oh J, Jeong D, et al. Direct wiring of eutectic gallium-indium to a metal electrode for soft sensor systems. ACS Appl Mater Interfaces, 2019, 11: 20557–20565

Ji Z, Sun W, Wang H, et al. Research on the cooling effect of semiconductor refrigeration chip. In: 2011 2nd International Conference on Artificial Intelligence, Management Science and Electronic Commerce (AIMSEC). Dengleng, 2011. 4272–4275

Cheng YH, Lin WK. Geometric optimization of thermoelectric coolers in a confined volume using genetic algorithms. Appl Therm Eng, 2005, 25: 2983–2997

Fan S, Gao Y, Rezania A. Thermoelectric performance and stress analysis on wearable thermoelectric generator under bending load. Renew Energy, 2021, 173: 581–595

Xu F, Zhu Y. Highly conductive and stretchable silver nanowire conductors. Adv Mater, 2012, 24: 5117–5122

Guo R, Yao S, Sun X, et al. Semi-liquid metal and adhesion-selection enabled rolling and transfer (SMART) printing: A general method towards fast fabrication of flexible electronics. Sci China Mater, 2019, 62: 982–994

He J, Tritt TM. Advances in thermoelectric materials research: Looking back and moving forward. Science, 2017, 357: 9997

Fabián-Mijangos A, Min G, Alvarez-Quintana J. Enhanced performance thermoelectric module having asymmetrical legs. Energy Convers Manage, 2017, 148: 1372–1381

Twaha S, Zhu J, Yan Y, et al. A comprehensive review of thermoelectric technology: Materials, applications, modelling and performance improvement. Renew Sustain Energy Rev, 2016, 65: 698–726

Li H, Xiao S, Yu H, et al. A review of graphene-based films for heat dissipation. New Carbon Mater, 2021, 36: 897–908

Zhang L, Han X, Du M, et al. Compliant three-dimensional thermoelectric generator filled with porous PDMS for power generation and solid-state cooling. Compos Commun, 2021, 26: 100793

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (52203371 and 52271021). The authors thank the Analysis & Testing Center and Micro & Nano Fabrication Center at Beijing Institute of Technology for technical supports on SEM/XRD/XPS characterizations.

Author information

Authors and Affiliations

Contributions

Author contributions Huo Y and Yang M conceived and designed the experiments. Yang M and Li G did the synthesis experiments and wrote the manuscript draft. Yang M and Huo Y analyzed the data and wrote the manuscript. Yang M, Li G, Gu Y, Song J, Li H, Zhao X and Huo Y contributed to the data analysis. All authors contributed to the general discussion.

Corresponding authors

Ethics declarations

Conflict of interest The authors declare that they have no conflict of interest.

Additional information

Mingkun Yang is a doctoral candidate at Beijing Institute of Technology (BIT), China, under the supervision of Prof. Yongjun Huo. His research focuses on the electronic packaging technology, high-density integrated circuit packaging, and transient liquid phase microconnects.

YongJun Huo is currently a pre-appointed associate professor at BIT. He is currently the head of the university-level experimental platform for heterogeneous integration of micro and nano materials. He received his PhD degree from the University of California, Irvine in 2017, under the supervision of Prof. Chin C. Lee, an IEEE Lifetime Fellow, who was awarded the IEEE EPS Award in 2021. He has eight years of overseas working experience in the US and has been committed to the academic research of high-reliability integrated circuits and high-power chip packaging technology. He was granted one international PCT patent for his invention of low-temperature micro-connection technology, which can fundamentally solve a series of common technical problems that have long hindered the development of aerospace-specific electronic packaging and integration technology. His main research direction is high-power optoelectronic device packaging, heterogeneous material integration processes, low-temperature transient liquid-phase micro-nano interconnects, and high-resolution transmission electron microscopy materials characterization.

Supplementary information Supporting data are available in the online version of the paper.

Rights and permissions

About this article

Cite this article

Yang, M., Li, G., Gu, Y. et al. Liquid metal-based flexible and wearable thermoelectric cooling structure and cooling performance optimization. Sci. China Mater. 66, 4001–4011 (2023). https://doi.org/10.1007/s40843-023-2607-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40843-023-2607-3