Abstract

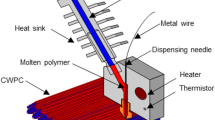

Thermal conduction pathways play crucial roles in comprehending thermal transport in thermally conductive polymer composites. However, there is a lack of in-depth investigation on how the thermal conduction pathways (length and number) influence the thermal conductivity coefficients (λ) of the composites. In this work, three-dimensional (3D) printing is performed to fabricate the thermally conductive 1D copper wire/poly(lactic acid) (1D-Cw/PLA) composites, allowing for controlling the length and number of Cw thermal conduction pathways. And one thermal conduction model is also proposed and established for polymer composites with 1D thermal conduction pathways, elucidating the quantitative relationship between thermal conduction pathways and thermal conductivity. For composites with the same amount of Cw, the in-plane λ (λ//) of thermally conductive 1D-Cw/PLA composites is positively correlated with the number and length of Cw thermal conduction pathways. Specifically, when the volume fraction of Cw is 25.1 vol%, the λ// of 1D-Cw/PLA composites, containing 20 intact Cw thermal conduction pathways, can reach up to 4.23 W m−1 K−1, which is 87.2% higher than that of 1D-Cw/PLA composites without intact Cw thermal conduction pathways (2.26 W m−1 K−1), 72.0% higher than that of 1D-Cw/PLA composites with short Cw (2 intact Cw and 18 Cw broken at the half, 2.46 W m−1 K−1), and 1527% higher than that of the pure PLA matrix (0.26 W m−1 K−1). Furthermore, the predicted λ values from our established thermal conduction model and empirical equation show no significant difference from the measured λ at a 95% confidence level.

摘要

导热通路对理解导热高分子复合材料的导热行为至关重要, 但目前有关导热通路属性(长度、 数量)对高分子复合材料导热系数的影响机制缺乏深入研究. 本文采用3D打印技术制备了铜线(Cw)导热通路长度和数量可控的一维铜线/聚乳酸(1D-Cw/PLA)导热复合材料, 建立了针对一维导热通路的高分子复合材料的导热模型, 明晰了其导热通路属性与其导热性能的定量关系. 相同Cw用量下, 1D-Cw/PLA导热复合材料的面内导热系数与导热通路的数量和长度呈正相关. 采用本文构建的导热模型和经验方程对1D-Cw/PLA复合材料的导热系数进行预测, 95%的置信度表明预测值与实测值无显著差异.

Similar content being viewed by others

References

Li MD, Shen XQ, Chen X, et al. Thermal management of chips by a device prototype using synergistic effects of 3-D heat-conductive network and electrocaloric refrigeration. Nat Commun, 2022, 13: 5849

Lin Y, Kang Q, Wei H, et al. Spider web-inspired graphene skeleton-based high thermal conductivity phase change nanocomposites for battery thermal management. Nano-Micro Lett, 2021, 13: 180

Chen J, Huang X, Sun B, et al. Highly thermally conductive yet electrically insulating polymer/boron nitride nanosheets nanocomposite films for improved thermal management capability. ACS Nano, 2019, 13: 337–345

Zhang H, He Q, Yu H, et al. A bioinspired polymer-based composite displaying both strong adhesion and anisotropic thermal conductivity. Adv Funct Mater, 2023, 33: 2211985

Shi X, Zhang R, Ruan K, et al. Improvement of thermal conductivities and simulation model for glass fabrics reinforced epoxy laminated composites via introducing hetero-structured BNN-30@BNNS fillers. J Mater Sci Tech, 2021, 82: 239–249

Kim D, Lee YJ, Ahn KH. Interconnected network of Ag and Cu in bioplastics for ultrahigh electromagnetic interference shielding efficiency with high thermal conductivity. Compos Commun, 2022, 30: 101093

Wang Z, Fan JF, He D, et al. Superior stretchable, low thermal resistance and efficient self-healing composite elastomers for thermal management. J Mater Chem A, 2022, 10: 21923–21932

Chen Y, Zhang H, Chen J, et al. Thermally conductive but electrically insulating polybenzazole nanofiber/boron nitride nanosheets nanocomposite paper for heat dissipation of 5G base stations and transformers. ACS Nano, 2022, 16: 14323–14333

Wang S, Wen B. Effect of functional filler morphology on the crystallization behavior and thermal conductivity of PET resin: A comparative study of three different shapes of BN as heterogeneous nucleating agents. Compos Sci Tech, 2022, 222: 109346

Yang S, Wang Q, Wen B. Highly thermally conductive and superior electrical insulation polymer composites via in situ thermal expansion of expanded graphite and in situ oxidation of aluminum nanoflakes. ACS Appl Mater Interfaces, 2021, 13: 1511–1523

Cao M, Li Z, Lu J, et al. Vertical array of graphite oxide liquid crystal by microwire shearing for highly thermally conductive composites. Adv Mater, 2023, 35: 2300077

Ruan K, Shi X, Zhang Y, et al. Electric-field-induced alignment of functionalized carbon nanotubes inside thermally conductive liquid crystalline polyimide composite films. Angew Chem Int Ed, 2023, 62: e202309010

Jiang J, Yang S, Li L, et al. High thermal conductivity polylactic acid composite for 3D printing: Synergistic effect of graphene and alumina. Polym Adv Technol, 2020, 31: 1291–1299

Barani Z, Mohammadzadeh A, Geremew A, et al. Thermal properties of the binary-filler hybrid composites with graphene and copper nanoparticles. Adv Funct Mater, 2020, 30: 1904008

Han G, Cheng H, He C, et al. Silver nanoparticles bridging segregated hexagonal boron nitride networks for enhancing the thermal conductivity of polystyrene composites. Compos Commun, 2022, 34: 101267

Dehdari Ebrahimi N, Ju YS. Thermal conductivity of sintered copper samples prepared using 3D printing-compatible polymer composite filaments. Additive Manufact, 2018, 24: 479–485

Yang S, Li W, Bai S, et al. Fabrication of morphologically controlled composites with high thermal conductivity and dielectric performance from aluminum nanoflake and recycled plastic package. ACS Appl Mater Interfaces, 2019, 11: 3388–3399

Lule Z, Kim J. Thermally conductive and highly rigid polylactic acid (PLA) hybrid composite filled with surface treated alumina/nano-sized aluminum nitride. Compos Part A-Appl Sci Manufact, 2019, 124: 105506

Wang Y, Jin H, Shen J, et al. Thermally conductive poly(lactic acid)/boron nitride composites via regenerated cellulose assisted Pickering emulsion approach. J Mater Sci Tech, 2022, 101: 146–154

Lee W, Kim J. Highly thermal conductive and electrical insulating epoxy composites with a three-dimensional filler network by sintering silver nanowires on aluminum nitride surface. Polymers, 2021, 13: 694

Han Y, Ruan K, Gu J. Multifunctional thermally conductive composite films based on fungal tree-like heterostructured silver nanowires@boron nitride nanosheets and aramid nanofibers. Angew Chem Int Ed, 2023, 62: e202216093

Zhang X, Li J, Gao Q, et al. Nerve-fiber-inspired construction of 3D graphene “tracks” supported by wood fibers for multifunctional biocomposite with metal-level thermal conductivity. Adv Funct Mater, 2023, 33: 2213274

Huang R, Ding D, Guo X, et al. Improving through-plane thermal conductivity of PDMS-based composites using highly oriented carbon fibers bridged by Al2O3 particles. Compos Sci Tech, 2022, 230: 109717

Chen S, Seveno D, Gorbatikh L. Multiscale modeling and maximizing the thermal conductivity of polyamide-6 reinforced by highly entangled graphene flakes. Compos Part A-Appl Sci Manufact, 2021, 151: 106632

Qian X, Zhou J, Chen G. Phonon-engineered extreme thermal conductivity materials. Nat Mater, 2021, 20: 1188–1202

Zheng H, Xu G, Wu K, et al. Highly intrinsic thermally conductive electrospinning film with intermolecular interaction. J Phys Chem C, 2021, 125: 21580–21587

Cao H, Li Y, Xu W, et al. Leakage-proof flexible phase change gels with salient thermal conductivity for efficient thermal management. ACS Appl Mater Interfaces, 2022, 14: 52411–52421

Zhang Y, Ruan K, Zhou K, et al. Controlled distributed Ti3C2Tx hollow microspheres on thermally conductive polyimide composite films for excellent electromagnetic interference shielding. Adv Mater, 2023, 35: 2211642

Sun D, Gu T, Mao Y, et al. Fabricating high-thermal-conductivity, high-strength, and high-toughness polylactic acid-based blend composites via constructing multioriented microstructures. Biomacromolecules, 2022, 23: 1789–1802

Ma TB, Ma H, Ruan KP, et al. Thermally conductive poly(lactic acid) composites with superior electromagnetic shielding performances via 3D printing technology. Chin J Polym Sci, 2022, 40: 248–255

He X, Ou D, Wu S, et al. A mini review on factors affecting network in thermally enhanced polymer composites: Filler content, shape, size, and tailoring methods. Adv Compos Hybrid Mater, 2022, 5: 21–38

Zhao C, Li Y, Liu Y, et al. A critical review of the preparation strategies of thermally conductive and electrically insulating polymeric materials and their applications in heat dissipation of electronic devices. Adv Compos Hybrid Mater, 2023, 6: 27

Agari Y, Ueda A, Nagai S. Thermal conductivity of a polyethylene filled with disoriented short-cut carbon fibers. J Appl Polym Sci, 1991, 43: 1117–1124

Hao M, Qian X, Zhang Y, et al. Thermal conductivity enhancement of carbon fiber/epoxy composites via constructing three-dimensionally aligned hybrid thermal conductive structures on fiber surfaces. Compos Sci Tech, 2023, 231: 109800

Privalko VP, Novikov VV (eds.). Thermal and Electrical Conductivity of Polymer Materials. Berlin & Heidelberg: Springer Berlin Heidelberg, 1995

Long Y, Zhang Z, Yan C, et al. Multi-objective optimization for improving printing efficiency and mechanical properties of 3D-printed continuous plant fibre composites. Compos Commun, 2022, 35: 101283

Guo H, Zhao H, Niu H, et al. Highly thermally conductive 3D printed graphene filled polymer composites for scalable thermal management applications. ACS Nano, 2021, 15: 6917–6928

Huttunen E, Nykänen MT, Alexandersen J. Material extrusion additive manufacturing and experimental testing of topology-optimised passive heat sinks using a thermally-conductive plastic filament. Additive Manufact, 2022, 59: 103123

Gao J, Hao M, Wang Y, et al. 3D printing boron nitride nanosheets filled thermoplastic polyurethane composites with enhanced mechanical and thermal conductive properties. Additive Manufact, 2022, 56: 102897

Guiney LM, Mansukhani ND, Jakus AE, et al. Three-dimensional printing of cytocompatible, thermally conductive hexagonal boron nitride nanocomposites. Nano Lett, 2018, 18: 3488–3493

Taleb O, Barzycki DC, Polanco CG, et al. Assessing effective medium theories for conduction through lamellar composites. Int J Heat Mass Transfer, 2022, 188: 122631

Chaudhary DR, Bhandari RC. Heat transfer through a three-phase porous medium. J Phys D-Appl Phys, 1968, 1: 815–817

Cai Y, Yu H, Chen C, et al. Improved thermal conductivities of vertically aligned carbon nanotube arrays using three-dimensional carbon nanotube networks. Carbon, 2022, 196: 902–912

Peng H, Huang J, Ren H, et al. Parallel structure enhanced polysilylarylenyne/Ca0.9La0.067TiO3 composites with ultra-high dielectric constant and thermal conductivity. ACS Appl Mater Interfaces, 2022, 14: 45893–45903

Potenza M, Petracci I, Corasaniti S. Transient thermal behaviour of high thermal conductivity graphene based composite materials: Experiments and theoretical models. Int J Thermal Sci, 2023, 188: 108253

Losego MD, Blitz IP, Vaia RA, et al. Ultralow thermal conductivity in organoclay nanolaminates synthesized via simple self-assembly. Nano Lett, 2013, 13: 2215–2219

Zhao S, Zhu R, Fu Y. Piezothermic transduction of functional composite materials. ACS Appl Mater Interfaces, 2019, 11: 4588–4596

Acknowledgements

This work was supported by the National Natural Science Foundation of China (51973173), the Technological Base Scientific Research Projects (Highly Thermal conductivity Nonmetal Materials), and the Fundamental Research Funds for the Central Universities. Ruan K would like to thank the Innovation Foundation for Doctor Dissertation of Northwestern Polytechnical University (CX2022073). This work was also financially supported by the Polymer Electromagnetic Functional Materials Innovation Team of Shaanxi Sanqin Scholars.

Author information

Authors and Affiliations

Contributions

Author contributions Gu J and Ma T designed the samples; Ma T and Guo Y performed the experiments; Ma T, Ruan K and Han Y performed the data analysis; Ma T and Ruan K wrote the paper with support from Gu J. All authors contributed to the general discussion.

Corresponding authors

Ethics declarations

Conflict of interest The authors declare that they have no conflict of interest.

Additional information

Tengbo Ma obtained his Bachelor degree from Northwestern Polytechnical University in 2016. Currently he is a PhD candidate majoring in materials science at Northwestern Polytechnical University. His research interests include structural optimization, performance improvement, and mechanism research of thermally conductive polymer composites.

Kunpeng Ruan obtained his Bachelor degree from Northwestern Polytechnical University in 2019. Currently he is a PhD candidate majoring in materials science at Northwestern Polytechnical University. His research interests include structural optimization, performance improvement and mechanism investigation of intrinsically thermally conductive polyimide and its composite films.

Yongqiang Guo obtained his PhD degree from Northwestern Polytechnical University in 2022. Currently he is a postdoc at Beihang University. His research interests focus on structural optimization, performance improvement and mechanism investigation of thermally conductive polymer composites.

Junwei Gu received his PhD degree from Northwestern Polytechnical University, China in 2010. He is a professor at the School of Chemistry and Chemical Engineering, Northwestern Polytechnical University. His research interests include thermally conductive polymers and composites, fiber-reinforced polymer matrix wave-transparent composites, and electromagnetic interference shielding polymer matrix composites.

Supplementary information Supporting data are available in the online version of the paper.

Supplementary information

40843_2023_2540_MOESM1_ESM.pdf

Controlled length and number of thermal conduction pathways for copper wire/poly(lactic acid) composites via 3D printing

Rights and permissions

About this article

Cite this article

Ma, T., Ruan, K., Guo, Y. et al. Controlled length and number of thermal conduction pathways for copper wire/poly(lactic acid) composites via 3D printing. Sci. China Mater. 66, 4012–4021 (2023). https://doi.org/10.1007/s40843-023-2540-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40843-023-2540-9