Abstract

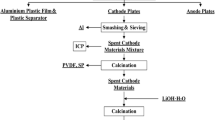

Recycling of spent lithium-ion batteries (LIBs) has raised wide concerns vis-à-vis resource value and environmental protection. Benefiting from the short process and high added value of the recycled products, the regeneration of cathode materials from spent LIBs is a popular approach. However, due to the lack of studies on fluorine (F) migration and the impact thereof on recycled materials, F control relies on deep removal and becomes a considerable challenge, limiting the generation of high-quality cathode materials. Herein, the migration-transformation behaviors of F are investigated in the integrated pyrolysis-leaching-regeneration process of spent LIBs. It is indicated that 45.71% of the amount of F is released into the atmosphere during pyrolysis and some amount of F in the leaching solution is adsorbed into coprecipitated precursors through coordination with metal ions and then regularly entering the lattices of the regenerated LiNi0.9Co0.05Mn0.05O2. Regarding the effects of F on the regenerated LiNi0.9Co0.05Mn0.05O2, a moderate F concentration (approximately 0.30 g L−1) in the leaching solution can boost the regenerated LiNi0.9Co0.05Mn0.05O2 material’s cycling stability (the capacity retention of 95.7% after 100 cycles at 1 C), due to the stabilizing effect of F-doping on the regenerated material’s structure. This study reveals the migration-transformation mechanisms of F during the recycling of spent LIB and provides a rational in-situ F-doping strategy for the regeneration of LiNi0.9Co0.05Mn0.05O2.

摘要

氟是废旧锂电池回收难以回避的典型杂质元素, 其迁移转化行 为复杂, 制约了高品质正极材料的可控再生制备. 本研究通过揭示废旧 锂电池在热解、浸出及高镍LiNi0.9Co0.05Mn0.05O2材料再生过程中氟的 迁移转化规律, 为氟的定向调控及材料的可控再生制备奠定理论基础. 实验结果表明: 热解过程中部分氟(45.71%)以气态热解产物的形式释 放到大气中, 而另一部分氟(52.34%)则向废三元材料的晶格内发生迁 移, 并随着湿法浸出溶解到镍钴锰的浸出液中. 浸出液中少量的氟会在 共沉淀制备前驱体过程中迁移到Ni0.9Co0.05Mn0.05(OH)2前驱体材料, 并 随着配锂烧结掺杂到再生LiNi0.9Co0.05Mn0.05O2材料表面. 进一步通过 调控氟含量发现, 当浸出液中氟浓度控制在0.30 g L−1时, 引入到再生 LiNi0.9Co0.05Mn0.05O2材料中的氟不仅不会引起不利相变, 而且能够稳 定材料结构, 从而有效提升再生高镍材料的循环稳定性(1 C电流密度 下循环100圈的容量保持率高达95.7%). 因此, 本研究不仅揭示了废旧 锂电池回收过程中氟的迁移转化行为, 而且可控再生制备了高性能氟 掺杂高镍LiNi0.9Co0.05Mn0.05O2正极材料, 为废旧锂离子电池回收过程 中氟的调控提供了理论依据.

Similar content being viewed by others

References

Park NY, Ryu HH, Kuo LY, et al. High-energy cathodes via precision microstructure tailoring for next-generation electric vehicles. ACS Energy Lett, 2021, 6: 4195–4202

Qiu L, Xiang W, Tian W, et al. Polyanion and cation co-doping stabilized Ni-rich Ni–Co–Al material as cathode with enhanced electrochemical performance for Li-ion battery. Nano Energy, 2019, 63: 103818

Yi C, Ge P, Wu X, et al. Tailoring carbon chains for repairing graphite from spent lithium-ion battery toward closed-circuit recycling. J Energy Chem, 2022, 72: 97–107

Meng YF, Liang HJ, Zhao CD, et al. Concurrent recycling chemistry for cathode/anode in spent graphite/LiFePO4 batteries: Designing a unique cation/anion-co-workable dual-ion battery. J Energy Chem, 2022, 64: 166–171

Du M, Guo JZ, Zheng SH, et al. Direct reuse of LiFePO4 cathode materials from spent lithium-ion batteries: Extracting Li from brine. Chin Chem Lett, 2023, 34: 107706

Gratz E, Sa Q, Apelian D, et al. A closed loop process for recycling spent lithium ion batteries. J Power Sources, 2014, 262: 255–262

Chu W, Zhang YL, Chen X, et al. Synthesis of LiNi0.6Co0.2Mn0.2O2 from mixed cathode materials of spent lithium-ion batteries. J Power Sources, 2020, 449: 227567

Peng F, Mu D, Li R, et al. Impurity removal with highly selective and efficient methods and the recycling of transition metals from spent lithium-ion batteries. RSC Adv, 2019, 9: 21922–21930

Zheng Z, Chen M, Wang Q, et al. High performance cathode recovery from different electric vehicle recycling streams. ACS Sustain Chem Eng, 2018, 6: 13977–13982

Chen Y, Liu N, Jie Y, et al. Toxicity identification and evolution mechanism of thermolysis-driven gas emissions from cathodes of spent lithium-ion batteries. ACS Sustain Chem Eng, 2019, 7: 18228–18235

Liu W, Zhong X, Han J, et al. Kinetic study and pyrolysis behaviors of spent LiFePO4 batteries. ACS Sustain Chem Eng, 2018, 7: 1289–1299

Wang M, Tan Q, Liu L, et al. Revealing the dissolution mechanism of polyvinylidene fluoride of spent lithium-ion batteries in waste oil-based methyl ester solvent. ACS Sustain Chem Eng, 2020, 8: 7489–7496

Yu W, Guo Y, Xu S, et al. Comprehensive recycling of lithium-ion batteries: Fundamentals, pretreatment, and perspectives. Energy Storage Mater, 2023, 54: 172–220

Zhang R, Meng Z, Ma X, et al. Understanding fundamental effects of Cu impurity in different forms for recovered LiNi0.6Co0.2Mn0.2O2 cathode materials. Nano Energy, 2020, 78: 105214

Wang X, Gu Z, Ang EH, et al. Prospects for managing end-of-life lithium-ion batteries: Present and future. Interdisciplinary Mater, 2022, 1: 417–433

Yao Y, Zhu M, Zhao Z, et al. Hydrometallurgical processes for recycling spent lithium-ion batteries: A critical review. ACS Sustain Chem Eng, 2018, 6: 13611–13627

Zhao Y, Yuan X, Jiang L, et al. Regeneration and reutilization of cathode materials from spent lithium-ion batteries. Chem Eng J, 2020, 383: 123089

Binder JO, Culver SP, Pinedo R, et al. Investigation of fluorine and nitrogen as anionic dopants in nickel-rich cathode materials for lithium-ion batteries. ACS Appl Mater Interfaces, 2018, 10: 44452–44462

Yang X, Dong P, Hao T, et al. A combined method of leaching and co-precipitation for recycling spent LiNi0.6Co0.2Mn0.2O2 cathode materials: Process optimization and performance aspects. JOM, 2020, 72: 3843–3852

Kong F, Liang C, Longo RC, et al. Conflicting roles of anion doping on the electrochemical performance of Li-ion battery cathode materials. Chem Mater, 2016, 28: 6942–6952

Zheng J, Liu T, Hu Z, et al. Tuning of thermal stability in layered Li(NixMnyCoz)O2. J Am Chem Soc, 2016, 138: 13326–13334

Woo SU, Park BC, Yoon CS, et al. Improvement of electrochemical performances of Li[Ni0.8Co0.1Mn0.1]O2 cathode materials by fluorine substitution. J Electrochem Soc, 2007, 154: A649

Li C, Kan WH, Xie H, et al. Inducing favorable cation antisite by doping halogen in Ni-rich layered cathode with ultrahigh stability. Adv Sci, 2019, 6: 1801406

Kim UH, Park GT, Conlin P, et al. Cation ordered Ni-rich layered cathode for ultra-long battery life. Energy Environ Sci, 2021, 14: 1573–1583

Dou X, Mohan D, Pittman Jr. CU, et al. Remediating fluoride from water using hydrous zirconium oxide. Chem Eng J, 2012, 198–199: 236–245

Jamil S, Wang G, Yang L, et al. Suppressing H2–H3 phase transition in high Ni-low Co layered oxide cathode material by dual modification. J Mater Chem A, 2020, 8: 21306–21316

Jie Y, Yang S, Hu F, et al. Gas evolution characterization and phase transformation during thermal treatment of cathode plates from spent LiFePO4 batteries. ThermoChim Acta, 2020, 684: 178483

Choi SS, Kim YK. Microstructural analysis of poly(vinylidene fluoride) using benzene derivative pyrolysis products. J Anal Appl Pyrolysis, 2012, 96: 16–23

Breddemann U, Krossing I. Review on synthesis, characterization, and electrochemical properties of fluorinated nickel-cobalt-manganese cathode active materials for lithium-ion batteries. ChemElectroChem, 2020, 7: 1389–1430

Li X, Xie Z, Liu W, et al. Effects of fluorine doping on structure, surface chemistry, and electrochemical performance of LiNi0.8Co0.15Al0.05O2. Electrochim Acta, 2015, 174: 1122–1130

Guo Y, Zhang C, Xin S, et al. Competitive doping chemistry for nickel-rich layered oxide cathode materials. Angew Chem Int Ed, 2022, 61: e202116865

Liu X, Wang S, Wang L, et al. Stabilizing the high-voltage cycle performance of LiNi0.8Co0.1Mn0.1O2 cathode material by Mg doping. J Power Sources, 2019, 438: 227017

Wu F, Tian J, Su Y, et al. Effect of Ni2+ content on lithium/nickel disorder for Ni-rich cathode materials. ACS Appl Mater Interfaces, 2015, 7: 7702–7708

Lv B, Liu Z, Ding R, et al. Fast production of β-Ni(OH)2 nanostructures with (001) and (100) plane exposure and their electrochemical properties. J Mater Chem A, 2013, 1: 5695–5699

Weigel T, Schipper F, Erickson EM, et al. Structural and electrochemical aspects of LiNi0.8Co0.1Mn0.1O2 cathode materials doped by various cations. ACS Energy Lett, 2019, 4: 508–516

Wang D, Kou R, Ren Y, et al. Synthetic control of kinetic reaction pathway and cationic ordering in high-Ni layered oxide cathodes. Adv Mater, 2017, 29: 1606715

Li Z, Li H, Cao S, et al. Reversible anionic redox and spinel-layered coherent structure enable high-capacity and long-term cycling of Li-rich cathode. Chem Eng J, 2023, 452: 139041

Cao S, Wu C, Xie X, et al. Suppressing the voltage decay based on a distinct stacking sequence of oxygen atoms for Li-rich cathode materials. ACS Appl Mater Interfaces, 2021, 13: 17639–17648

Jo M, Noh M, Oh P, et al. A new high power LiNi0.81Co0.1Al0.09O2 cathode material for lithium-ion batteries. Adv Energy Mater, 2014, 4: 1301583

Park H, Park H, Song K, et al. In situ multiscale probing of the synthesis of a Ni-rich layered oxide cathode reveals reaction heterogeneity driven by competing kinetic pathways. Nat Chem, 2022, 14: 614–622

Chang Q, Luo Z, Fu L, et al. A new cathode material of NiF2 for thermal batteries with high specific power. Electrochim Acta, 2020, 361: 137051

Lange BA, Haendler HM. The thermal decomposition of nickel and zinc fluoride tetrahydrates. J InOrg Nucl Chem, 1973, 35: 3129–3133

Lee W, Muhammad S, Kim T, et al. New insight into Ni-rich layered structure for next-generation Li rechargeable batteries. Adv Energy Mater, 2018, 8: 1701788

Xu C, Reeves PJ, Jacquet Q, et al. Phase behavior during electrochemical cycling of Ni-rich cathode materials for Li-ion batteries. Adv Energy Mater, 2021, 11: 2003404

Kim SB, Kim H, Park DH, et al. Li-ion diffusivity and electrochemical performance of Ni-rich cathode material doped with fluoride ions. J Power Sources, 2021, 506: 230219

Zhang C, Wan J, Li Y, et al. Restraining the polarization increase of Ni-rich and low-Co cathodes upon cycling by Al-doping. J Mater Chem A, 2020, 8: 6893–6901

Ryu HH, Park KJ, Yoon CS, et al. Capacity fading of Ni-rich Li[NixCayMn1−x−y]O2 (0.6 ⩽x ⩽ 0.95) cathodes for high-energy-density lithium-ion batteries: Bulk or surface degradation? Chem Mater, 2018, 30: 1155–1163

Sun HH, Manthiram A. Impact of microcrack generation and surface degradation on a nickel-rich layered Li[Ni0.9Co0.05Mn0.05]O2 cathode for lithium-ion batteries. Chem Mater, 2017, 29: 8486–8493

Aishova A, Park G, Yoon CS, et al. Cobalt-free high-capacity Ni-rich layered Li[Ni0.9Mn0.1]O2 cathode. Adv Energy Mater, 2019, 10: 1903179

Choi JU, Voronina N, Sun Y, et al. Recent progress and perspective of advanced high-energy Co-less Ni-rich cathodes for Li-ion batteries: Yesterday, today, and tomorrow. Adv Energy Mater, 2020, 10: 2002027

Li Z, Cao S, Xie X, et al. Boosting electrochemical performance of lithium-rich manganese-based cathode materials through a dual modification strategy with defect designing and interface engineering. ACS Appl Mater Interfaces, 2021, 13: 53974–53985

Li Z, Cao S, Wu C, et al. A facile and high-effective oxygen defect engineering for improving electrochemical performance of lithium-rich manganese-based cathode materials. J Power Sources, 2022, 536: 231456

Park N, Ryu H, Park G, et al. Optimized Ni-rich NCMA cathode for electric vehicle batteries. Adv Energy Mater, 2021, 11: 2003767

Acknowledgements

This work was supported by the National Natural Science Foundation of China (51904340), the Natural Science Foundation of Hunan (2021JJ2020066), the National Key Research and Development Program (2019YFC1907801, 2019YFC1907803 and 2019YFC1907804), and the Central South University Innovation-Driven Research Programme (2023CXQD009).

Author information

Authors and Affiliations

Contributions

Yang Y conceived the idea, supervised the project, guided the experiment, and revised the manuscript; Wang T performed the experiments, processed and analyzed the data, wrote the original manuscript, and revised the manuscript with support from Ge P, Yi C, Wu M, Zhang C, Wang L and Sun W. All authors contributed to the general discussion.

Corresponding author

Ethics declarations

The authors declare that they have no conflict of interest.

Additional information

Supplementary information

Supporting data are available in the online version of the paper.

Tianyu Wang received his Master’s degree from the Central South University in 2019. He is currently pursuing his PhD degree at the School of Minerals Processing and Bioengineering, Central South University. His research interests focus on recycling of spent LIBs and regeneration of high-energy cathode materials.

Chenxing Yi received his Master’s degree from Kunming University of Science and Technology in 2018. He is currently pursuing his PhD degree at the School of Minerals Processing and Bioengineering, Central South University. His research interests focus on recycling of spent LIBs.

Yue Yang received his PhD degree from the Institute of Nuclear and New Energy Technology, Tsinghua University in 2017. After graduation, he has been working at the School of Minerals Processing and Bioengineering, Central South University. His research interests focus on the recycling of spent LIBs and the preparation of energy materials.

Supplementary information

40843_2023_2512_MOESM1_ESM.pdf

Fluorine migration and in-situ doping for regeneration of Ni-rich LiNi0.9Co0.05Mn0.05O2 cathode material from spent lithium-ion batteries

Rights and permissions

About this article

Cite this article

Wang, T., Yi, C., Ge, P. et al. Fluorine migration and in-situ doping for regeneration of Ni-rich LiNi0.9Co0.05Mn0.05O2 cathode material from spent lithium-ion batteries. Sci. China Mater. 66, 3433–3444 (2023). https://doi.org/10.1007/s40843-023-2512-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40843-023-2512-1