Abstract

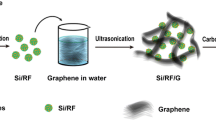

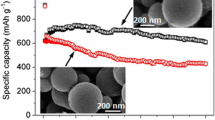

A watermelon-like internally inflated core-buffer-shell structural Si/electrochemically exfoliated graphene/C (Si/EG/C) composite is designed and prepared by the industrially established ball milling and spray drying method. Owing to numerous folds and voids in the EG filled between nano silicon and carbon shell, the volume fluctuations of silicon inside the Si/EG/C particles are buffered and lithium ions also could transport fast through the channels. With these advantages, the core-buffer-shell structural Si/EG/C composite demonstrates excellent electrochemical performance. The Si/EG/C anodes in half cells exhibit no degradation of the initial capacity (834 mA h g−1) after 100 cycles. Moreover, the Si/EG/C//LiCoO2 full cells retain almost 100% of the initial discharge capacity after 500 cycles. These results highlight the potential applications of Si/EG/C in the next generation of Li-ion batteries.

摘要

本文采用球磨和喷雾干燥法, 制备了类西瓜型可控内膨胀核-缓冲-壳结构Si/电化学剥离石墨烯/C(Si/EG/C)复合材料. 在纳米硅和碳壳之间填充了含大量褶皱和空隙的EG, 不仅缓冲了Si/EG/C颗粒内部硅的体积变化, 还提供了锂离子的快速传输通道. 凭借这些优势, 核-缓冲-壳结构的Si/EG/C表现出优异的电化学性能. 半电池中Si/EG/C负极在100次循环后相对于初始容量没有下降(834 mA h g−1). 此外, Si/EG/C//LiCoO2全电池在500次循环后相对于初始放电容量的容量保持率接近100%. 这些结果表明Si/EG/C在下一代锂离子电池中具有潜在应用前景.

Similar content being viewed by others

References

Jin Y, Zhu B, Lu Z, et al. Challenges and recent progress in the development of Si anodes for lithium-ion battery. Adv Energy Mater, 2017, 7: 1700715

Zhang M, Zhang T, Ma Y, et al. Latest development of nanostructured Si/C materials for lithium anode studies and applications. Energy Storage Mater, 2016, 4: 1–14

Wang MS, Wang GL, Wang S, et al. In situ catalytic growth 3D multilayers graphene sheets coated nano-silicon anode for high performance lithium-ion batteries. Chem Eng J, 2019, 356: 895–903

Casimir A, Zhang H, Ogoke O, et al. Silicon-based anodes for lithiumion batteries: Effectiveness of materials synthesis and electrode preparation. Nano Energy, 2016, 27: 359–376

Feng K, Li M, Liu W, et al. Silicon-based anodes for lithium-ion batteries: From fundamentals to practical applications. Small, 2018, 14: 1702737

Zhang X, Kong D, Li X, et al. Dimensionally designed carbon-silicon hybrids for lithium storage. Adv Funct Mater, 2019, 29: 1806061

Zuo X, Zhu J, Müller-Buschbaum P, et al. Silicon based lithium-ion battery anodes: A chronicle perspective review. Nano Energy, 2017, 31: 113–143

Zhang L, Wang C, Dou Y, et al. A yolk-shell structured silicon anode with superior conductivity and high tap density for full lithium-ion batteries. Angew Chem Int Ed, 2019, 58: 8824–8828

Shen X, Tian Z, Fan R, et al. Research progress on silicon/carbon composite anode materials for lithium-ion battery. J Energy Chem, 2018, 27: 1067–1090

Huang X, Sui X, Yang H, et al. Hf-free synthesis of Si/C yolk/shell anodes for lithium-ion batteries. J Mater Chem A, 2018, 6: 2593–2599

Chen H, Ling M, Hencz L, et al. Exploring chemical, mechanical, and electrical functionalities of binders for advanced energy-storage devices. Chem Rev, 2018, 118: 8936–8982

Chen H, Wang S, Liu X, et al. Double-coated Si-based composite composed with carbon layer and graphene sheets with void spaces for lithium-ion batteries. Electrochim Acta, 2018, 288: 134–143

Novoselov KS, Geim AK, Morozov SV, et al. Electric field effect in atomically thin carbon films. Science, 2004, 306: 666–669

Paredes JI, Munuera JM. Recent advances and energy-related applications of high quality/chemically doped graphenes obtained by electrochemical exfoliation methods. J Mater Chem A, 2017, 5: 7228–7242

Liu XH, Zhong L, Huang S, et al. Size-dependent fracture of silicon nanoparticles during lithiation. ACS Nano, 2012, 6: 1522–1531

Li P, Hwang JY, Sun YK. Nano/microstructured silicon-graphite composite anode for high-energy-density Li-ion battery. ACS Nano, 2019, 13: acsnano.9b00169

David L, Bhandavat R, Barrera U, et al. Silicon oxycarbide glass-graphene composite paper electrode for long-cycle lithium-ion batteries. Nat Commun, 2016, 7: 10998

Tian S, Yang S, Huang T, et al. One-step fast electrochemical fabrication of water-dispersible graphene. Carbon, 2017, 111: 617–621

Li Z, Bommier C, Chong ZS, et al. Mechanism of Na-ion storage in hard carbon anodes revealed by heteroatom doping. Adv Energy Mater, 2017, 7: 1602894

Jamaluddin A, Umesh B, Chen F, et al. Facile synthesis of core-shell structured Si@graphene balls as a high-performance anode for lithium-ion batteries. Nanoscale, 2020, 12: 9616–9627

Ma C, Wang Z, Zhao Y, et al. A novel raspberry-like yolk-shell structured Si/C micro/nano-spheres as high-performance anode materials for lithium-ion batteries. J Alloys Compd, 2020, 844: 156201

Shi L, Pang C, Chen S, et al. Vertical graphene growth on SiO microparticles for stable lithium ion battery anodes. Nano Lett, 2017, 17: 3681–3687

Ambrosi A, Bonanni A, Sofer Z, et al. Electrochemistry at chemically modified graphenes. Chem Eur J, 2011, 17: 10763–10770

Wu S, Lan D, Zhang X, et al. Microwave hydrothermal synthesis, characterization and excellent uranium adsorption properties of CoFe2O4@rGO nanocomposite. J Cent South Univ, 2021, 28: 1955–1965

Li L, Zhang D, Deng J, et al. Review—Preparation and application of graphene-based hybrid materials through electrochemical exfoliation. J Electrochem Soc, 2020, 167: 086511

Wu W, Zhang C, Hou S. Electrochemical exfoliation of graphene and graphene-analogous 2D nanosheets. J Mater Sci, 2017, 52: 10649–10660

Chen H, Shen K, Hou X, et al. Si-based anode with hierarchical protective function and hollow ring-like carbon matrix for high performance lithium ion batteries. Appl Surf Sci, 2019, 470: 496–506

Zhang Y, Mu Z, Lai J, et al. MXene/Si@SiOx@C layer-by-layer superstructure with autoadjustable function for superior stable lithium storage. ACS Nano, 2019, 13: acsnano.8b08821

Su J, Zhao J, Li L, et al. Three-dimensional porous Si and SiO2 with in situ decorated carbon nanotubes as anode materials for Li-ion batteries. ACS Appl Mater Interfaces, 2017, 9: 17807–17813

Zhang J, Zhang X, Hou Z, et al. Uniform SiOx/graphene composite materials for lithium ion battery anodes. J Alloys Compd, 2019, 809: 151798

Wang K, Pei S, He Z, et al. Synthesis of a novel porous silicon microsphere@carbon core-shell composite via in situ MOF coating for lithium ion battery anodes. Chem Eng J, 2019, 356: 272–281

Li Y, Yan K, Lee HW, et al. Growth of conformal graphene cages on micrometre-sized silicon particles as stable battery anodes. Nat Energy, 2016, 1: 15029

Liu X, Zhang J, Si W, et al. Sandwich nanoarchitecture of Si/reduced graphene oxide bilayer nanomembranes for Li-ion batteries with long cycle life. ACS Nano, 2015, 9: 1198–1205

Xu Q, Sun JK, Yin YX, et al. Facile synthesis of blocky SiOx/C with graphite-like structure for high-performance lithium-ion battery anodes. Adv Funct Mater, 2018, 28: 1705235

Wang B, Ryu J, Choi S, et al. Ultrafast-charging silicon-based coral-like network anodes for lithium-ion batteries with high energy and power densities. ACS Nano, 2019, 13: acsnano.8b09034

Liang G, Qin X, Zou J, et al. Electrosprayed silicon-embedded porous carbon microspheres as lithium-ion battery anodes with exceptional rate capacities. Carbon, 2018, 127: 424–431

Liu N, Lu Z, Zhao J, et al. A pomegranate-inspired nanoscale design for large-volume-change lithium battery anodes. Nat Nanotech, 2014, 9: 187–192

Yu WJ, Liu C, Hou PX, et al. Lithiation of silicon nanoparticles confined in carbon nanotubes. ACS Nano, 2015, 9: 5063–5071

Wang N, Liu YY, Shi ZX, et al. Electrolytic silicon/graphite composite from SiO2/graphite porous electrode in molten salts as a negative electrode material for lithium-ion batteries. Rare Met, 2021, 41: 438–447

Sun L, Xie J, Huang S, et al. Rapid CO2 exfoliation of zintl phase CaSi2-derived ultrathin free-standing Si/SiOx/C nanosheets for high-performance lithium storage. Sci China Mater, 2021, 65: 51–58

Ke CZ, Liu F, Zheng ZM, et al. Boosting lithium storage performance of Si nanoparticles via thin carbon and nitrogen/phosphorus co-doped two-dimensional carbon sheet dual encapsulation. Rare Met, 2021, 40: 1347–1356

Wang A, Liu F, Wang Z, et al. Self-assembly of silicon/carbon hybrids and natural graphite as anode materials for lithium-ion batteries. RSC Adv, 2016, 6: 104995–105002

Su M, Liu S, Tao L, et al. Silicon@graphene composite prepared by spray-drying method as anode for lithium ion batteries. J Electroanal Chem, 2019, 844: 86–90

Chen X, Chen C, Zhang Y, et al. Exploiting oleic acid to prepare two-dimensional assembly of Si@graphitic carbon yolk-shell nanoparticles for lithium-ion battery anodes. Nano Res, 2018, 12: 631–636

Xiao Z, Xia N, Song L, et al. Synthesis of yolk-shell-structured Si@C nanocomposite anode material for lithium-ion battery. J Elec Materi, 2018, 47: 6311–6318

Hu L, Luo B, Wu C, et al. Yolk-shell Si/C composites with multiple Si nanoparticles encapsulated into double carbon shells as lithium-ion battery anodes. J Energy Chem, 2019, 32: 124–130

Li Z, Yao N, Zhao H, et al. Communication-self-template fabrication of porous Si/SiOx/C anode material for lithium-ion batteries. J Electrochem Soc, 2020, 167: 020555

Wang R, Feng D, Chen T, et al. Mussel-inspired polydopamine treated Si/C electrode as high-performance anode for lithium-ion batteries. J Alloys Compd, 2020, 825: 154081

Acknowledgements

This work was supported by the National Key R&D Program of China (2018YFB0905400), the Key Laboratory Open Project of Guangdong Province (2018B030322001), and the National Natural Science Foundation of China (52172201, 51732005 and 11905081). The authors thank the Analytical and Testing Centre of HUST for material characterization.

Author information

Authors and Affiliations

Contributions

Zhang Z performed the experiments; Sun S designed the samples; Zhang W characterized the samples; Xu J performed the electrochemical measurements; Wang X analyzed the data; Fang C and Li Q contributed to the theoretical analysis; Zhang Z and Sun S wrote the paper with the support from Han J.

Corresponding authors

Additional information

Supplementary information Supporting data are available in the online version of the paper.

Conflict of interest

The authors declare that they have no conflict of interest.

Zeyu Zhang is currently a master’s candidate at Huazhong University of Science and Technology (HUST). She received her BSc degree from Chongqing University in 2019. Her research interests focus on anode materials for lithium-ion batteries.

Shixiong Sun received his PhD degree from HUST in 2019. Presently, he is a postdoctoral researcher at the School of Materials Science and Engineering, HUST. His research focuses on energy storage materials for secondary batteries.

Chun Fang received her PhD degree from Fudan University in 2008. She then worked as a senior engineer at Evergreen Solar Corp. from 2009 to 2012. After that, she was an R&D manager at Empower Energy Corp. from 2012 to 2015. Currently, she is a research associate at HUST. Her research interests focus on new materials for energy storage applications.

Jiantao Han is a professor at the School of Materials Science and Engineering, HUST. He received his PhD degree in chemistry from Fudan University in 2007 and then worked at UT Austin (2007–2010), Los Alamos National Laboratory (2010–2012), and Pellion Tech. (2012–2014). He joined HUST as a full professor in 2016. His research interests include atomic distribution function (PDF) analysis and Li-ion batteries.

Electronic supplementary material

Rights and permissions

About this article

Cite this article

Zhang, Z., Sun, S., Zhang, W. et al. Internally inflated core-buffer-shell structural Si/EG/C composites as high-performance anodes for lithium-ion batteries. Sci. China Mater. 65, 2949–2957 (2022). https://doi.org/10.1007/s40843-022-2083-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40843-022-2083-2