Abstract

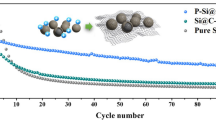

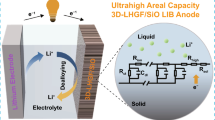

Silicon (Si) is a promising anode material for next-generation Li-ion batteries. The nanometer-sized Si could alleviate the pulverization caused by large volume changes during deep cycling. However, compression between agglomerated Si particles causes Si cracking and electrode failure. Considering this, we engineered a mechanical cushioning space between Si particles via elastic hollow graphene shells (GSs) to flexibly buffer volume changes and maintain the stability of the electrode structure. The stress generated from the Si volume expansion during lithiation was mechanically buffered and gently released by compression of the hollow space of the GS. In this Si/GS composite electrode, GS also reduced the local agglomeration of Si particles and effectively improved the overall conductivity. Considering these advantages, the designed Si/GS electrode showed an enhanced cycling performance with more than 1200 mA h g−1 at 0.8 A g−1 and an excellent rate capability of 1025 mA h g−1 at 4 A g−1 after 200 cycles.

摘要

硅被认为是下一代锂离子电池极具潜力的负极材料. 纳米硅的使用缓解了其在锂化时因体积变化引起的颗粒粉碎化. 然而, 团聚的硅颗粒间的相互挤压仍然会引起硅负极的迅速失效. 为此, 我们以弹性的石墨烯空心球为媒介在硅粒子之间引入机械缓冲空间, 来灵活缓冲硅的体积变化, 保持电极结构的稳定性. 在锂化过程中, 硅体积膨胀产生的应力通过压缩石墨烯空心球的内部空心得到了机械式的缓冲. 除此之外, 石墨烯空心球还减少了硅颗粒的局部团聚, 有效地提高了整体电导率. 基于这些优势, 所设计的Si/GS电极在0.8 A g−1的电流密度下循环 200圈后性能仍维持在1200 mA h g−1以上; 在4 A g−1的电流密度下, 200次循环后仍可达到1025 mA h g−1.

Similar content being viewed by others

References

Zhang X, Cheng X, Zhang Q. Nanostructured energy materials for electrochemical energy conversion and storage: A review. J Energy Chem, 2016, 25: 967–984

Linares N, Silvestre-Albero AM, Serrano E, et al. Mesoporous materials for clean energy technologies. Chem Soc Rev, 2014, 43: 7681–7717

Dunn B, Kamath H, Tarascon JM. Electrical energy storage for the grid: A battery of choices. Science, 2011, 334: 928–935

Chen X, Li H, Yan Z, et al. Structure design and mechanism analysis of silicon anode for lithium-ion batteries. Sci China Mater, 2019, 62: 1515–1536

Liu N, Lu Z, Zhao J, et al. A pomegranate-inspired nanoscale design for large-volume-change lithium battery anodes. Nat Nanotech, 2014, 9: 187–192

Yao Y, McDowell MT, Ryu I, et al. Interconnected silicon hollow nanospheres for lithium-ion battery anodes with long cycle life. Nano Lett, 2011, 11: 2949–2954

Sun L, Xie J, Huang S, et al. Rapid CO2 exfoliation of Zintl phase CaSi2-derived ultrathin free-standing Si/SiOx/C nanosheets for high-performance lithium storage. Sci China Mater, 2022, 65: 51–58

Zhou W, Chen J, Xu X, et al. Interface engineering of silicon and carbon by forming a graded protective sheath for high-capacity and long-durable lithium-ion batteries. ACS Appl Mater Interfaces, 2021, 13: 15216–15225

Chae S, Kwak WJ, Han KS, et al. Rational design of electrolytes for long-term cycling of Si anodes over a wide temperature range. ACS Energy Lett, 2021, 6: 387–394

Yang G, Frisco S, Tao R, et al. Robust solid/electrolyte interphase (SEI) formation on Si anodes using glyme-based electrolytes. ACS Energy Lett, 2021, 6: 1684–1693

Chen H, Wu Z, Su Z, et al. A hydrophilic poly(methyl vinyl ether-alt-maleic acid) polymer as a green, universal, and dual-functional binder for high-performance silicon anode and sulfur cathode. J Energy Chem, 2021, 62: 127–135

Hu S, Cai Z, Huang T, et al. A modified natural polysaccharide as a high-performance binder for silicon anodes in lithium-ion batteries. ACS Appl Mater Interfaces, 2019, 11: 4311–4317

Liu XH, Zhong L, Huang S, et al. Size-dependent fracture of silicon nanoparticles during lithiation. ACS Nano, 2012, 6: 1522–1531

Shen X, Tian Z, Fan R, et al. Research progress on silicon/carbon composite anode materials for lithium-ion battery. J Energy Chem, 2018, 27: 1067–1090

Dou F, Shi L, Chen G, et al. Silicon/carbon composite anode materials for lithium-ion batteries. Electrochem Energ Rev, 2019, 2: 149–198

Shi Q, Zhou J, Ullah S, et al. A review of recent developments in Si/C composite materials for Li-ion batteries. Energy Storage Mater, 2021, 34: 735–754

Liu N, Wu H, McDowell MT, et al. A yolk-shell design for stabilized and scalable Li-ion battery alloy anodes. Nano Lett, 2012, 12: 3315–3321

Chen X, Ge G, Wang W, et al. In situ formation of ionically conductive nanointerphase on Si particles for stable battery anode. Sci China Chem, 2021, 64: 1417–1425

Zhao C, Wada T, De Andrade V, et al. Imaging of 3D morphological evolution of nanoporous silicon anode in lithium ion battery by X-ray nano-tomography. Nano Energy, 2018, 52: 381–390

Beattie SD, Larcher D, Morcrette M, et al. Si electrodes for Li-ion batteries—A new way to look at an old problem. J Electrochem Soc, 2008, 155: A158

Schroder K, Alvarado J, Yersak TA, et al. The effect of fluoroethylene carbonate as an additive on the solid electrolyte interphase on silicon lithium-ion electrodes. Chem Mater, 2015, 27: 5531–5542

Chen L, Wang K, Xie X, et al. Effect of vinylene carbonate (VC) as electrolyte additive on electrochemical performance of Si film anode for lithium ion batteries. J Power Sources, 2007, 174: 538–543

Rahman MA, Song G, Bhatt AI, et al. Nanostructured silicon anodes for high-performance lithium-ion batteries. Adv Funct Mater, 2016, 26: 647–678

Zhang M, Zhang T, Ma Y, et al. Latest development of nanostructured Si/C materials for lithium anode studies and applications. Energy Storage Mater, 2016, 4: 1–14

Damle SS, Pal S, Kumta PN, et al. Effect of silicon configurations on the mechanical integrity of silicon-carbon nanotube heterostructured anode for lithium ion battery: A computational study. J Power Sources, 2016, 304: 373–383

Guo J, Zhai W, Sun Q, et al. Facilely tunable core-shell Si@SiOx nanostructures prepared in aqueous solution for lithium ion battery anode. Electrochim Acta, 2020, 342: 136068

Kühne M, Börrnert F, Fecher S, et al. Reversible superdense ordering of lithium between two graphene sheets. Nature, 2018, 564: 234–239

Kim IH, Yun T, Kim JE, et al. Mussel-inspired defect engineering of graphene liquid crystalline fibers for synergistic enhancement of mechanical strength and electrical conductivity. Adv Mater, 2018, 30: 1803267

Jiang T, Zhang S, Qiu X, et al. Preparation and characterization of silicon-based three-dimensional cellular anode for lithium ion battery. Electrochem Commun, 2007, 9: 930–934

Chan CK, Peng H, Liu G, et al. High-performance lithium battery anodes using silicon nanowires. Nat Nanotech, 2008, 3: 31–35

Han J, Chen G, Yan T, et al. Creating graphene-like carbon layers on SiO anodes via a layer-by-layer strategy for lithium-ion battery. Chem Eng J, 2018, 347: 273–279

Xu C, Lindgren F, Philippe B, et al. Improved performance of the silicon anode for Li-ion batteries: Understanding the surface modification mechanism of fluoroethylene carbonate as an effective electrolyte additive. Chem Mater, 2015, 27: 2591–2599

Profatilova IA, Stock C, Schmitz A, et al. Enhanced thermal stability of a lithiated nano-silicon electrode by fluoroethylene carbonate and vinylene carbonate. J Power Sources, 2013, 222: 140–149

Tarascon JM, Armand M. Issues and challenges facing rechargeable lithium batteries. Nature, 2001, 414: 359–367

Li N, Sun L, Wang K, et al. Sandwiched N-carbon@Co9S8@graphene nanosheets as high capacity anode for both half and full lithium-ion batteries. J Energy Chem, 2020, 51: 62–71

Ding N, Xu J, Yao YX, et al. Determination of the diffusion coefficient of lithium ions in nano-Si. Solid State Ion, 2009, 180: 222–225

Ge G, Li G, Wang X, et al. Manipulating oxidation of silicon with fresh surface enabling stable battery anode. Nano Lett, 2021, 21: 3127–3133

Dahn JR, Zheng T, Liu Y, et al. Mechanisms for lithium insertion in carbonaceous materials. Science, 1995, 270: 590–593

Aurbach D, Ein-Eli Y. The study of Li-graphite intercalation processes in several electrolyte systems using in situ X-ray diffraction. J Electrochem Soc, 1995, 142: 1746–1752

Acknowledgements

This work was supported by the National Natural Science Foundation of China (52071225, 52172240, 51702225 and 51672181), Czech Republic through the ERDF “Institute of Environmental Technology-Excellent Research” grant (CZ.02.1.01/0.0/0.0/16_019/0008533), the Sino-German Research Institute for their support (Project GZ 1400), the Fundamental Research Funds for the Central Universities (20720200075), Beijing Municipal Science and Technology Commission (Z161100002116020), and the Natural Science Foundation of Jiangsu Province (BK20170336).

Author information

Authors and Affiliations

Contributions

Author contributions Shi Q and Ye W performed the experiments and co-wrote the paper. Kurtyka K, Wang H, Lia X and Ta HQ helped analyze the data and reviewed the paper. Rümmeli MH conceived and supervised the study. All authors contributed to the general discussion.

Corresponding authors

Ethics declarations

Conflict of interest The authors declare that they have no conflicts of interest.

Additional information

Supplementary information Experimental details and supporting data are available in the online version of the paper.

Qitao Shi received his bachelor of science degree from the Department of Physics and Optoelectronic Energy, Soo-chow University, in 2016. He is currently working as a doctoral researcher at Soochow Institute for Energy and Materials Innovations (SIEMIS) and College of Energy, Soochow University in Prof. Mark H. Rümmeli’s group. His current research focuses on solving the pulverization issues of Si particles used as anode materials via space engineering or structure optimization.

Ming-Sheng Wang is currently a Minjiang Scholar Chair professor at Xiamen University, and he leads the Advanced Electron Microscopy group at the College of Materials. He received his bachelor’s degree in physics from Nanjing University (2001) and PhD degree in physical electronics from Peking University (2006) in China. He did his postdoctoral research at the National Institute for Materials Science (NIMS) in Japan and Massachusetts Institute of Technology (MIT) from 2008 to 2012. His research interests concentrate on the in-situ electron microscopy, TEM-based precise nanomanufacturing, and the design and characterization of high-performance energy storage devices based on low-dimensional material architectures. Group website: http://mswang.xmu.edu.cn.

Mark H. Rümmeli headed the Electron Microscopy and LIN laboratories at SIEMIS, Soochow University, where he is a full professor. He is also the director of the characterization center of the College of Energy and SIEMES. He obtained his PhD degree from London Metropolitan University and worked as a postdoc at German Aerospace Center. His research focuses on the growth mechanisms of 2D nanostructures and their functionalization.

Rights and permissions

About this article

Cite this article

Shi, Q., Ye, W., Kurtyka, K. et al. Enhanced performance of Si-based Li-ion batteries through elastic cushioning with hollow graphene shells. Sci. China Mater. 65, 2343–2353 (2022). https://doi.org/10.1007/s40843-021-2031-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40843-021-2031-8