Abstract

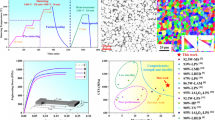

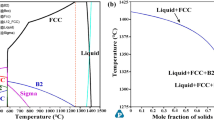

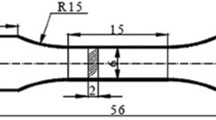

The design of metallic materials with high strength, high ductility, and high thermal stability has always been a long-sought goal for the materials science community. However, the trade-off between strength and ductility remains a challenge. Here, we proposed a new strategy to design and fabricate bulk amorphous—crystalline dual-phase superior alloys out of the Al80Li5Mg5Zn5Cu5 multicomponent alloy. The nano-amorphous phase revealed unexpected thermal stability during fabrication and mechanical testing above the crystallization temperature. The true fracture strength of the Al80Li5Mg5Zn5Cu5 nano-amorphous-crystal dual-phase multicomponent alloy was increased from 528 to 657 MPa, and the true strain was increased from 18% to 48%. In addition, the alloy yielded a strength 1.5 times higher than that of the commonly used high-strength aluminum alloys at 250°C. This strategy provided a new approach and concept for the design of high-performance alloys to ensure strength—plasticity balance.

摘要

设计具有高强度、 高延展性和高热稳定性的金属材料, 一直是材料科学界追求的目标. 强度和延展性之间的平衡始终面临挑战. 本文中, 我们以Al80Li5Mg5Zn5Cu5多组元合金为模型, 提出了一种设计并制造大块非晶-结晶双相优质合金的新策略. 得到的Al80Li5Mg5Zn5Cu5纳米非晶双相合金的真实断裂强度从528 MPa提高到657 MPa, 真实应变从18%提高到48%. 纳米非晶相在热制造和高于结晶温度的力学性能测试中展现出优异的热稳定性, 使得该合金在250°C时的屈服强度, 比常用的高强度铝合金高出1.5倍. 这一策略为高性能合金的设计、 制造提供了一种新的方法和概念.

Similar content being viewed by others

References

Raabe D, Tasan CC, Olivetti EA. Strategies for improving the sustainability of structural metals. Nature, 2019, 575: 64–74

Li Z, Pradeep KG, Deng Y, et al. Metastable high-entropy dual-phase alloys overcome the strength—ductility trade-off. Nature, 2016, 534: 227–230

Ritchie RO. The conflicts between strength and toughness. Nat Mater, 2011, 10: 817–822

Wei Y, Li Y, Zhu L, et al. Evading the strength—ductility trade-off dilemma in steel through gradient hierarchical nanotwins. Nat Commun, 2014, 5: 3580

Shi P, Zhong Y, Li Y, et al. Multistage work hardening assisted by multi-type twinning in ultrafine-grained heterostructural eutectic high-entropy alloys. Mater Today, 2020, 41: 62–71

Jiao ZB, Luan JH, Miller MK, et al. Precipitation mechanism and mechanical properties of an ultra-high strength steel hardened by nanoscale NiAl and Cu particles. Acta Mater, 2015, 97: 58–67

Kim SH, Kim H, Kim NJ. Brittle intermetallic compound makes ultrastrong low-density steel with large ductility. Nature, 2015, 518: 77–79

Fleischer RL, Zabala RJ. Mechanical properties of diverse binary high-temperature intermetallic compounds. Metall Trans A, 1990, 21: 2709–2715

Jiang S, Wang H, Wu Y, et al. Ultrastrong steel via minimal lattice misfit and high-density nanoprecipitation. Nature, 2017, 544: 460–464

Yang T, Zhao YL, Tong Y, et al. Multicomponent intermetallic nanoparticles and superb mechanical behaviors of complex alloys. Science, 2018, 362: 933–937

Wu G, Chan KC, Zhu L, et al. Dual-phase nanostructuring as a route to high-strength magnesium alloys. Nature, 2017, 545: 80–83

He G, Eckert J, Löser W, et al. Novel Ti-base nanostructure—dendrite composite with enhanced plasticity. Nat Mater, 2003, 2: 33–37

Gertsman VY, Birringer R. On the room-temperature grain growth in nanocrystalline copper. Scripta Metall Mater, 1994, 30: 577–581

Wang JQ, Shen Y, Perepezko JH, et al. Increasing the kinetic stability of bulk metallic glasses. Acta Mater, 2016, 104: 25–32

Singh S, Ediger MD, de Pablo JJ. Ultrastable glasses from in SiLiCo vapour deposition. Nat Mater, 2013, 12: 139–144

Wu G, Balachandran S, Gault B, et al. Crystal—glass high-entropy nanocomposites with near theoretical compressive strength and large deformability. Adv Mater, 2020, 32: 2002619

Wu G, Liu C, Sun L, et al. Hierarchical nanostructured aluminum alloy with ultrahigh strength and large plasticity. Nat Commun, 2019, 10: 5099

Guo H, Yan PF, Wang YB, et al. Tensile ductility and necking of metallic glass. Nat Mater, 2007, 6: 735–739

Jang D, Greer JR. Transition from a strong-yet-brittle to a stronger-and-ductile state by size reduction of metallic glasses. Nat Mater, 2010, 9: 215–219

Hofmann DC, Suh JY, Wiest A, et al. Designing metallic glass matrix composites with high toughness and tensile ductility. Nature, 2008, 451: 1085–1089

Schawe JEK, Löffler JF. Existence of multiple critical cooling rates which generate different types of monolithic metallic glass. Nat Commun, 2019, 10: 1

Gangopadhyay AK, Croat TK, Kelton KF. The effect of phase separation on subsequent crystallization in Al88Gd6La2Ni4. Acta Mater, 2000, 48: 4035–4043

Li H, Wang A, Liu T, et al. Design of Fe-based nanocrystalline alloys with superior magnetization and manufacturability. Mater Today, 2021, 42: 49–56

Greer AL. Confusion by design. Nature, 1993, 366: 303–304

George EP, Raabe D, Ritchie RO. High-entropy alloys. Nat Rev Mater, 2019, 4: 515–534

Guo S, Liu CT. Phase stability in high entropy alloys: Formation of solid-solution phase or amorphous phase. Prog Nat Sci-Mater Int, 2011, 21: 433–446

Huang Z, Dai Y, Li Z, et al. Investigation on surface morphology and crystalline phase deformation of Al80Li5Mg5Zn5Cu5 high-entropy alloy by ultra-precision cutting. Mater Des, 2020, 186: 108367

Li R, Li X, Ma J, et al. Sub-grain formation in Al—Li—Mg—Zn—Cu lightweight entropic alloy by ultrasonic hammering. Intermetallics, 2020, 121: 106780

Udoye NE, Inegbenebor AO, Fayomi OSI. The study on improvement of aluminium alloy for engineering application: A review. Int J Mech Eng Technol, 2019, 10: 380–385

Dursun T, Soutis C. Recent developments in advanced aircraft aluminium alloys. Mater Des (1980–2015), 2014, 56: 862–871

Lee H, Choi JH, Jo MC, et al. Effects of SiC particulate size on dynamic compressive properties in 7075-T6 Al-SiCp composites. Mater Sci Eng-A, 2018, 738: 412–419

Öz T, Karaköse E, Keskin M. Impact of beryllium additions on thermal and mechanical properties of conventionally solidified and melt-spun Al—4.5wt.%Mn—xwt.%Be (x=0, 1, 3, 5) alloys. Mater Des, 2013, 50: 399–412

Zupanič F, Gspan C, Burja J, et al. Quasicrystalline and L12 precipitates in a microalloyed Al-Mn-Cu alloy. Mater Today Commun, 2020, 22: 100809

Taheri-Mandarjani M, Zarei-Hanzaki A, Abedi HR. Hot ductility behavior of an extruded 7075 aluminum alloy. Mater Sci Eng-A, 2015, 637: 107–122

Liu W, Zhao H, Li D, et al. Hot deformation behavior of aa7085 aluminum alloy during isothermal compression at elevated temperature. Mater Sci Eng-A, 2014, 596: 176–182

Nath Verma T, Banerjee M, Nashine P. Hot compression test of aa 2014 aluminum alloy with microstructure analysis and processing maps. Mater Today-Proc, 2018, 5: 7247–7255

Yang Y, Peng X, Ren F, et al. Constitutive modeling and hot deformation behavior of duplex structured Mg—Li—Al—Sr alloy. J Mater Sci Tech, 2016, 32: 1289–1296

Wang CY, Wu K, Zheng MY. Hot deformation behavior of Al18B4O33w/ZK60 magnesium matrix composite. Mater Sci Eng-A, 2008, 487: 495–498

He H, Yi Y, Cui J, et al. Hot deformation characteristics and processing parameter optimization of 2219 Al alloy using constitutive equation and processing map. Vacuum, 2019, 160: 293–302

Hansen N. Hall—petch relation and boundary strengthening. Scripta Mater, 2004, 51: 801–806

Hall EO. The deformation and ageing of mild steel: III Discussion of results. Proc Phys Soc B, 1951, 64: 747–753

Petch N. The cleavage strength of polycrystals. J Iron Steel Res Int, 1953, 174: 25–28

Liu YH, Wang G, Wang RJ, et al. Super plastic bulk metallic glasses at room temperature. Science, 2007, 315: 1385–1388

Li YY, Yang C, Chen WP, et al. Ultrafine-grained Ti66Nb13Cu8Ni6.8Al6.2 composites fabricated by spark plasma sintering and crystallization of amorphous phase. J Mater Res, 2009, 24: 2118–2122

Li YY, Yang C, Qu SG, et al. Nucleation and growth mechanism of crystalline phase for fabrication of ultrafine-grained Ti66Nb13Cu8Ni6.8Al6.2 composites by spark plasma sintering and crystallization of amorphous phase. Mater Sci Eng-A, 2010, 528: 486–493

Lee TC, Chan LC, Wu BJ. Straining behaviour in blanking process-fine blanking vs conventional blanking. J Mater Proc Tech, 1995, 48: 105–111

Murayama M, Howe JM, Hidaka H, et al. Atomic-level observation of disclination dipoles in mechanically milled, nanocrystalline Fe. Science, 2002, 295: 2433–2435

Ovid’ko IA. Deformation of nanostructures. Science, 2002, 295: 2386

Volkert CA, Donohue A, Spaepen F. Effect of sample size on deformation in amorphous metals. J Appl Phys, 2008, 103: 083539

Acknowledgements

This work was supported by the Key Basic and Applied Research Program of Guangdong Province, China (2019B030302010), the National Natural Science Foundation of China (52122105 and 51871157), the National Key Research and Development Program of China (2018YFA0703604). Thanks to Dr. Tong Xing from Guangdong Songshan Lake Materials Laboratory for his contribution to the TEM in-situ heating experiments.

Author information

Authors and Affiliations

Contributions

Author contributions Li H and Ma J conceived the experiments. Li H, Fu J, Cai W, and Yan Y performed the experiments. Yang C analyzed the data. Li H and Ma J wrote the manuscript with contributions from other authors.

Corresponding author

Ethics declarations

Conflict of interest The authors declare no conflict of interest.

Additional information

Supplementary information Experimental details and supporting data are available in the online version of the paper.

Hongzhen Li received his master degree in mechanical engineering from Shenzhen University (SZU) in 2020. Currently, he is studying for a PhD at South China University of Technology. His research includes metallic glass, high-entropy alloys and advanced manufacturing.

Jiang Ma received his BSc degree in materials science and engineering from Southeast University in 2009 and PhD degree from the Institute of Physics, Chinese Academy of Sciences (CAS), in 2014. He is currently a Professor at the College of Mechatronics and Control Engineering, SZU. His research includes metallic glass, high-entropy alloy, micro/nano precision forming, and functional surface fabrication and application.

Supplementary information

Rights and permissions

About this article

Cite this article

Li, H., Yang, C., Fu, J. et al. Nano-amorphous—crystalline dual-phase design of Al80Li5Mg5Zn5Cu5 multicomponent alloy. Sci. China Mater. 65, 1671–1678 (2022). https://doi.org/10.1007/s40843-021-1934-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40843-021-1934-x