Abstract

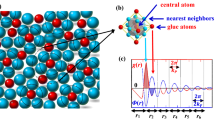

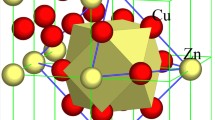

Each conventional alloy has its own specific compositions but the compositional origin is largely unknown due to our insufficient understanding about chemical short-range ordering in the alloy, in particular, in the solid-solution state. In the present paper, the compositions of metallic alloys are discussed and formulated, by unveiling the basic moleculelike structural units in solid solutions. Friedel oscillation theory, which describes the partial charge screening behavior in solid solutions, and henceforth the origin of short-range ordering, is applied to pin down the ideal chemical compositions of conventional metallic alloys. We propose that, at a specific composition, atoms self-assemble into an ideally ordered structure consisting of atoms residing in the nearest-neighbor shell (denoted as cluster) plus those in the next outer shell (denoted as glue atoms), which can be formulated as [cluster](glue atoms). This simplified version of short-range-order structure represents the smallest charge-neutral and mean-density zone (termed as “chemical units”) and can be regarded as the ‘molecules’ of solid solutions. Accordingly, the chemical units and the corresponding molecule-like formulas for face-centered-cubic (FCC), hexagonal close-packed (HCP), and body-centered cubic (BCC) structures are analyzed and equations are obtained to identify the chemical formulas for FCC solid solutions. For instance, well-known α-brass Cu-30Zn alloy is formulated as [Zn-Cu12]Zn4. Examples of aluminum alloys, superalloys and stainless steels are also illustrated, demonstrating the versatility of the present model to interpret chemically complex alloys.

摘要

本文引入Friedel振荡理论, 揭示固溶体合金中存在类似分子 式的结构单元, 指出在特定的成分下, 合金中的原子在近程序上倾 向于聚集为理想的有序结构, 这个结构包括最近邻壳层原子(记作 团簇)和次近邻壳层原子(记作连接原子), 用团簇式: [团簇](连接原 子)来表示. 这种近程序结构被称为化学结构单元, 类似于固溶体中 的“分子”. 本文给出了FCC结构固溶体合金中化学结构单元的计算 公式, 通过计算得到Cu基二元体系的理想化学结构单元, 包括Cu-Zn、Cu-Al、Cu-Ni、Cu-Be和Cu-Sn, 均为工业中最常用的合金成 分. 此外, 工业上常用的多元合金, 如Al合金5083和7075、高温合金 TMS-196和TMS-82、马氏体时效不锈钢Cutom-465和奥氏体不锈 钢310s, 其成分均满足模型的预测, 表明本模型可以为FCC结构复 杂固溶体合金的成分设计提供理论指导.

Similar content being viewed by others

References

Cowley JM. An approximate theory of order in alloys. Phys Rev, 1950, 77: 669–675

Cahn RW. Homo or hetero? Nature, 1978, 271: 407–408

Hume-Rothery W, Smallman RE, Haworth CW. The Structure of Metals and Alloys. London: The Institute of Metals, 1988

Jones H. Notes on work at the University of Bristol, 1930–7. Proc R Soc Lond A, 1980, 371: 52–55

Friedel J. Electronic structure of primary solid solutions in metals. Adv Phys, 1954, 3: 446–507

Ziman JM. Principles of the Theory of Solids. Cambridge: Cambridge University Press, 1972

Häussler P. Interrelations between atomic and electronic structures—Liquid and amorphous metals as model systems. Phys Rep, 1992, 222: 65–143

Chen H, Wang Q, Wang Y, et al. Composition rule for Al-transition metal binary quasicrystals. Philos Mag, 2010, 90: 3935–3946

Baker H, Okamoto H. Alloy phase diagrams. Materials Park: ASM International, 1992

Davis JR. ASM Bandbook. 2. Properties and Selection: Nonferrous Alloys and Special-purpose aterials. Materials Park: ASM International, 2009

Reinhard L, Schönfeld B, Kostorz G, et al. Short-range order in α-brass. Phys Rev B, 1990, 41: 1727–1734

Stolz UK, Arpshofen I, Sommer P, et al. Determination of the enthalpy of mixing of liquid alloys using a high-temperature mixing calorimeter. JPE, 1993, 14: 473–478

Aalders J, van Dijk C, Radelaar S. Neutron scattering study of short-range clustering in CuNi(Fe) alloys. J Phys F-Met Phys, 1984, 14: 2801–2815

Koo YM, Cohen JB. The structure of GP zones in Cu-10.9 at.% Be. Acta Metall, 1989, 37: 1295–1306

Sato A, Harada H, Yeh AC, et al. A 5th generation SC superalloy with balanced high temperature properties and processability. Minerals Metals Mater Soc, 2008: 131–138

Pearson WB, Villars P, Calvert LD. Pearson’s Handbook of Crystallographic Data for Intermetallic Phases. Vol. 1. Materials Park: ASM International, 1985

Mughrabi H. Microstructural aspects of high temperature deformation of monocrystalline nickel base superalloys: Some open problems. Mater Sci Tech, 2009, 25: 191–204

Zhang JX, Harada H, Ro Y, et al. Thermomechanical fatigue mechanism in a modern single crystal nickel base superalloy TMS-82. Acta Mater, 2008, 56: 2975–2987

Jiang X, Ice GE, Sparks CJ, et al. Local atomic order and individual pair displacements of Fe46.5Ni53.5 and Fe22.5Ni77.5 from diffuse X-ray scattering studies. Phys Rev B, 1996, 54: 3211–3226

Tavares SSM, Moura V, da Costa VC, et al. Microstructural changes and corrosion resistance of AISI 310S steel exposed to 600–800°C. Mater Charact, 2009, 60: 573–578

Li ZM, Li XN, Hu YL, et al. Cuboidal γ′ phase coherent precipitation-strengthened Cu-Ni-Al alloys with high softening temperature. Acta Mater, 2021, 203: 116458

Li JL, Li Z, Wang Q, et al. Phase-field simulation of coherent BCC/ B2 microstructures in high entropy alloys. Acta Mater, 2020, 197: 10–19

Acknowledgements

This work was supported by the National Natural Science Foundation of China (51801017), the Key Discipline and Major Project of Dalian Science and Technology Innovation Foundation (2020JJ25CY004), the Subject Development Foundation of Key Laboratory of Surface Physics and Chemistry (XKFZ201706), the State Key Lab of Advanced Metals and Materials (2018-Z03), and the Scientific Challenge Program for National Defense Basic Scientific Research (TZ2016004). Nieh TG was supported by the US National Science Foundation under Contract DMR-0905979.

Author information

Authors and Affiliations

Contributions

Dong D conducted the major calculations and analyzed the alloy data. Wang Q interpreted the steel and the superalloy. Dong C proposed the theory. Nieh TG refined the manuscript. All authors participated in writing the paper.

Corresponding authors

Additional information

Conflict of interest

The authors declare that they have no conflict of interest.

Dong Dandan is a lecturer at the College of Physical Science and Technology, Dalian University She obtained her PhD degree in condensed matter physics at the School of Materials Science and Engineering, Dalian University of Technology. Her research interests focus on structural modeling and composition design of complex alloys, including metallic glasses, solid solutions, and lead-free solders.

Chuang Dong is a professor at the Key Laboratory of Materials Modification, Dalian University of Technology He obtained his PhD degree in materials science in 1991 at Institut National Polytechique de Lorraine, France. He was awarded the Outstanding Young Researcher in 1995 and Changjiang Professor in 2005, respectively. His research interests include structural modeling of disordered materials, alloy design, and surface modification.

Tai-Gang Nieh received his PhD degree in materials science and engineering from Stanford University. He is a world leader in superplasticity and superplastic forming. He is also widely recognized for his work in several material science disciplines, including multicomponent complex alloys (including high-entropy alloys and bulk metallic glasses), nanocrystalline materials, lightweight alloys, metal-matrix composites, intermetallics, refractory metals, and nanolaminates.

Rights and permissions

About this article

Cite this article

Dong, D., Wang, Q., Dong, C. et al. Molecule-like chemical units in metallic alloys. Sci. China Mater. 64, 2563–2571 (2021). https://doi.org/10.1007/s40843-020-1659-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40843-020-1659-1