Abstract

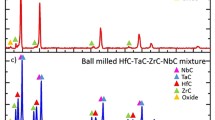

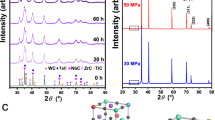

High-entropy ceramics (HECs) have attracted much attention due to their huge composition space, unique microstructure, and desirable properties. In contrast to previous studies, which have primarily focused on HECs with one anion, herein, we report a new family of ceramics with both multi-cationic and -anionic structures, i.e., high-entropy carbide-nitrides (Ti0.33Zr0.33Hf0.33)(C0.5N0.5), (Ti0.25Zr0.25Hf0.25Nb0.25)(C0.5N0.5) and (Ti0.2Zr0.2Hf0.2Nb0.2Ta0.2)(C0.5N0.5). These as-synthesized HECs are mainly comprised of a face-centered cubic solid-solution phase accompanied by minor inevitable oxide phases. The formation mechanism of the solid-solution phase is discussed in terms of the lattice size difference and thermodynamic competition between configurational entropy and mixing enthalpy. It is found that the increment in the configurational entropy can effectively lower the sintering temperature and increase the fracture toughness. Particularly, the newly developed (Ti0.2Zr0.2Hf0.2Nb0.2Ta0.2)(C0.5N0.5) exhibits a decent fracture toughness of 8.4 MPa m1/2 and a low sintering temperature of 1750°C, making it promising for ultra-high temperature applications. Our work not only enriches knowledge regarding the HECs categories, but also opens a new pathway for developing HECs with multi-cationic and -anionic structures.

摘要

高熵陶瓷由于具有巨大的成分空间、 独特的微观结构和良好的性能而倍受关注. 与现有高熵陶瓷研究主要集中在以单个阴离子和多个阳离子组成的混合结构不同, 本文报道了一系列具有多阴离子和多阳离子混合而成的新型高熵陶瓷: (Ti0.33Zr0.33Hf0.33)(C0.5N0.5), (Ti0.25Zr0.25Hf0.25Nb0.25)(C0.5N0.5)和(Ti0.2Zr0.2Hf0.2Nb0.2-Ta0.2)(C0.5N0.5). 这类高熵陶瓷主要由面心立方固溶体相组成, 同时伴随着少量不可避免的氧化物相. 从晶格尺寸差、 构型熵和混合焓的竞争关系对其形成机制进行了分析讨论. 由于多阴离子带来的高熵效应, 新开发的高熵陶瓷材料具有良好的断裂韧性和易烧结性. 特别是, (Ti0.2Zr0.2Hf0.2Nb0.2Ta0.2)(C0.5N0.5)的断裂韧性高达8.4 MPa m1/2, 具有作为超高温防护材料的应用前景. 该工作不仅丰富了高熵陶瓷的种类, 而且为开发具有多阴离子和阳离子结构的高熵陶瓷提供了新的思路.

Similar content being viewed by others

References

Rost CM, Sachet E, Borman T, et al. Entropy-stabilized oxides. Nat Commun, 2015, 6: 8485

Sarkar A, Wang Q, Schiele A, et al. High-entropy oxides: Fundamental aspects and electrochemical properties. Adv Mater, 2019, 31: 1806236

Wang D, Liu Z, Du S, et al. Low-temperature synthesis of small-sized high-entropy oxides for water oxidation. J Mater Chem A, 2019, 7: 24211–24216

Bérardan D, Franger S, Meena AK, et al. Room temperature lithium superionic conductivity in high entropy oxides. J Mater Chem A, 2016, 4: 9536–9541

Anand G, Wynn AP, Handley CM, et al. Phase stability and distortion in high-entropy oxides. Acta Mater, 2018, 146: 119–125

Jiang S, Hu T, Gild J, et al. A new class of high-entropy perovskite oxides. Scripta Mater, 2018, 142: 116–120

Yan X, Constantin L, Lu Y, et al. (Hf0.2Zr0.2Ta0.2Nb0.2Ti0.2)C high-entropy ceramics with low thermal conductivity. J Am Ceram Soc, 2018, 101: 4486–4491

Sarker P, Harrington T, Toher C, et al. High-entropy high-hardness metal carbides discovered by entropy descriptors. Nat Commun, 2018, 9: 4980

Rost CM, Borman T, Hossain MD, et al. Electron and phonon thermal conductivity in high entropy carbides with variable carbon content Acta Mater, 2020, 196: 231–239

Ye B, Wen T, Nguyen MC, et al. First-principles study, fabrication and characterization of (Zr0.25Nb0.25Ti0.25V0.25)C high-entropy ceramics Acta Mater, 2019, 170: 15–23

Harrington TJ, Gild J, Sarker P, et al. Phase stability and mechanical properties of novel high entropy transition metal carbides. Acta Mater, 2019, 166: 271–280

Ye B, Wen T, Liu D, et al. Oxidation behavior of (Hf0.2Zr0.2Ta0.2Nb0.2Ti0.2)C high-entropy ceramics at 1073–1473 K in air. Corrosion Sci, 2019, 153: 327–332

Feng L, Fahrenholtz WG, Hilmas GE, et al. Synthesis of singlephase high-entropy carbide powders Scripta Mater, 2019, 162: 90–93

Qin M, Yan Q, Wang H, et al. High-entropy monoborides: Towards superhard materials. Scripta Mater, 2020, 189: 101–105

Gild J, Kaufmann K, Vecchio K, et al. Reactive flash spark plasma sintering of high-entropy ultrahigh temperature ceramics. Scripta Mater, 2019, 170: 106–110

Zhang Y, Guo WM, Jiang ZB, et al. Dense high-entropy boride ceramics with ultra-high hardness. Scripta Mater, 2019, 164: 135–139

Liu D, Wen T, Ye B, et al. Synthesis of superfine high-entropy metal diboride powders. Scripta Mater, 2019, 167: 110–114

Mayrhofer PH, Kirnbauer A, Ertelthaler P, et al. High-entropy ceramic thin films; A case study on transition metal diborides. Scripta Mater, 2018, 149: 93–97

Fahrenholtz WG, Hilmas GE. Ultra-high temperature ceramics: Materials for extreme environments. Scripta Mater, 2017, 129: 94–99

Tallarita G, Licheri R, Garroni S, et al. Novel processing route for the fabrication of bulk high-entropy metal diborides. Scripta Mater, 2019, 158: 100–104

Jin T, Sang X, Unocic RR, et al. Mechanochemical-assisted synthesis of high-entropy metal nitride via a soft urea strategy. Adv Mater, 2018, 30: 1707512

Lei Z, Liu X, Wu Y, et al. Enhanced strength and ductility in a high-entropy alloy via ordered oxygen complexes. Nature, 2018, 563: 546–550

Huang TD, Jiang L, Zhang CL, et al. Effect of carbon addition on the microstructure and mechanical properties of CoCrFeNi high entropy alloy. Sci China Technol Sci, 2018, 61: 117–123

Rogal L, Bobrowski P, Körmann F, et al. Computationally-driven engineering of sublattice ordering in a hexagonal AlHfScTiZr high entropy alloy. Sci Rep, 2017, 7: 2209–2214

Wen T, Liu H, Ye B, et al. High-entropy alumino-silicides: a novel class of high-entropy ceramics. Sci China Mater, 2020, 63: 300–306

Guan J, Li D, Yang Z, et al. Synthesis and thermal stability of novel high-entropy metal boron carbonitride ceramic powders. Ceramics Int, 2020, 46: 26581–26589

Liu D, Zhang A, Jia J, et al. Phase evolution and properties of (VNbTaMoW)C high entropy carbide prepared by reaction synthesis. J Eur Ceramic Soc, 2020, 40: 2746–2751

Demirskyi D, Borodianska H, Suzuki TS, et al. High-temperature flexural strength performance of ternary high-entropy carbide consolidated via spark plasma sintering of TaC, ZrC and NbC. Scripta Mater, 2019, 164: 12–16

Yang T, Zhao YL, Tong Y, et al. Multicomponent intermetallic nanoparticles and superb mechanical behaviors of complex alloys. Science, 2018, 362: 933–937

Yang T, Zhao YL, Liu WP, et al. Ultrahigh-strength and ductile superlattice alloys with nanoscale disordered interfaces. Science, 2020, 369: 427–432

Liu D, Huang Y, Liu L, et al. A novel of MSi2 high-entropy silicide: Be expected to improve mechanical properties of MoSi2. Mater Lett, 2020, 268: 127629

Oliver WC, Pharr GM. Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J Mater Res, 2004, 19: 3–20

Oliver WC, Pharr GM. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J Mater Res, 1992, 7: 1564–1583

Guo S, Liu CT. Phase stability in high entropy alloys: Formation of solid-solution phase or amorphous phase. Prog Nat Sci-Mater Int, 2011, 21: 433–446

Gild J, Zhang Y, Harrington T, et al. High-entropy metal diborides: A new class of high-entropy materials and a new type of ultrahigh temperature ceramics. Sci Rep, 2016, 6: 37946

Egami T, Waseda Y. Atomic size effect on the formability of metallic glasses. J Non-Crystalline Solids, 1984, 64: 113–134

Yeh JW, Chen SK, Lin SJ, et al. Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv Eng Mater, 2004, 6: 299–303

Niihara K. A fracture mechanics analysis of indentation-induced Palmqvist crack in ceramics. J Mater Sci Lett, 1983, 2: 221–223

Niihara K, Morena R, Hasselman DPH. Evaluation of KIc of brittle solids by the indentation method with low crack-to-indent ratios. Mater Sci Lett, 1982, 1: 13–16

Zhang C, Gupta A, Seal S, et al. Solid solution synthesis of tantalum carbide-hafnium carbide by spark plasma sintering. J Am Ceram Soc, 2017, 100: 1853–1862

Hu Y, Huang JH, Zuo JM. In situ characterization of fracture toughness and dynamics of nanocrystalline titanium nitride films. J Mater Res, 2016, 31: 370–379

Alexandre N, Desmaison-Brut M, Valin F, et al. Mechanical properties of hot isostatically pressed zirconium nitride materials. J Mater Sci, 1993, 28: 2385–2390

Zhao X, Li H, Li J, et al. Mechanical and tribological behaviors of hard and tough TaxHf1−xN films with various Ta contents. Surf Coatings Tech, 2020, 403: 126412

Liu J, Liang C. The improvement of toughness and tribological properties of niobium nitride film by addition of copper. Vacuum, 2017, 143: 59–62

Yung DL, Hussainova I, Rodriguez MA, et al. Processing of ZrC-TiC composites by SPS. Key Eng Mater, 2016, 674: 94–99

Acknowledgements

This research was supported by the National Natural Science Foundation of China (51671021, 51961160729, 1179029, 51871016 and 51971017), the Funds for Creative Research Groups of China (51921001), 111 Project (B07003), the Program for Changjiang Scholars and Innovative Research Team in University of China (IRT_14R05), the Project of SKLAMM-USTB (2019Z-01) and the Project supported by the State Key Laboratory of Powder Metallurgy, Central South University, Changsha, China.

Author information

Authors and Affiliations

Contributions

Author contributions Liu X and Zhang P conceived the idea. Liu X and Lu Z supervised the project. Zhang P synthesized the samples and characterized the structural and mechanical properties. Zhang P, Liu X and Lu Z wrote the manuscript. All the authors analyzed the data and commented the manuscript.

Corresponding authors

Ethics declarations

Conflict of interest All authors declare that they have no conflict of interest.

Additional information

Pan Zhang is a PhD student at the State Key Laboratory for Advanced Metals and Materials, University of Science & Technology Beijing (USTB), under Prof. Liu’s supervision. His research focuses on the fabrication and characterization of high-entropy ceramics and related powders.

Xiongjun Liu is currently a full professor at USTB. He received his PhD degree from USTB in 2008, and worked as a post-doctoral fellow at the Hong Kong Polytechnic University for two and half years, from 2009 to 2012. His research interests mainly focus on the metallic glasses, high-entropy materials, nanoporous metals and computational materials science.

Zhaoping Lu is currently a full professor at USTB. He received his PhD degree from National University of Singapore in 2001, and worked as a post-doctoral fellow at Oak Ridge National Laboratory for three years, from 2001 to 2004. His research interests mainly focus on the metallic glasses, high-entropy materials, nanoporous metals and computational materials science.

Supplementary Information

Rights and permissions

About this article

Cite this article

Zhang, P., Liu, X., Cai, A. et al. High-entropy carbide-nitrides with enhanced toughness and sinterability. Sci. China Mater. 64, 2037–2044 (2021). https://doi.org/10.1007/s40843-020-1610-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40843-020-1610-9