Abstract

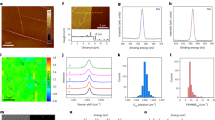

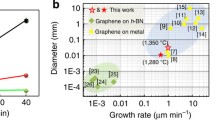

Bilayer graphene (BLG) shows great application prospect and potential in next-generation electronics because of its unique electrical and mechanical properties. However, the scalable synthesis of large-area high-quality BLG films is still a great challenge, despite the maturity of chemical vapor deposition (CVD) technique. In this study, we report a robust method to grow BLGs on flat, softened Cu foils by atmospheric pressure CVD. A moderate amount of residual oxygen accelerates the growth of BLG domains while suppressing the formation of multilayers. Raising the nucleation density at low hydrogen pressure efficiently increases the film continuity. Based on the optimized CVD process, the growth of graphene films on 4×4 cm2 Cu foils with an average BLG coverage of 76% is achieved. The morphology and structure characterizations demonstrate a high quality of the BLG. Dual gate field-effect transistors are investigated based on AB-stacked BLG, with a tunable bandgap and high carrier mobility of up to 6790 cm2 V−1 s−1 at room temperature.

摘要

双层石墨烯因其独特的物理性质在新型电子器件等领域具 有广阔的应用前景. 大面积高质量双层石墨烯的批量化制备是实 现其后续应用的关键. 目前, 基于铜表面自限制催化的化学气相沉 积法可有效实现单层石墨烯的生长, 但由于第二层石墨烯结构导 致更复杂的生长过程, 双层石墨烯的可控制备极具挑战性. 本文系 统研究了石墨烯的常压化学气相沉积制备过程, 提出了一种在软 化铜箔基底上生长高质量双层石墨烯的方法. 铜箔在随炉升温过 程中软化并贴合至背面的石英舟/管表面, 形成具有差异反应条件 的铜箔双面, 从而促使双层石墨烯在其正面生长. 反应系统中的残 余氧气有效加快了双层石墨烯的生长. 同时, 适量的残余氧气可抑 制三层及少数层石墨烯的形成, 提高双层石墨烯产物的均匀性. 基 于优化的生长条件, 在4×4 cm2铜箔上实现了双层覆盖率达76%的 高质量石墨烯薄膜的生长. 基于AB堆垛双层石墨烯的双栅场效应 晶体管, 室温载流子迁移率达6790 cm2 V−1 s−1. 本研究有助于推动 石墨烯等二维材料的层数可控合成技术的发展.

Similar content being viewed by others

References

Zhang Y, Tang TT, Girit C, et al. Direct observation of a widely tunable bandgap in bilayer graphene. Nature, 2009, 459: 820–823

Cao Y, Fatemi V, Fang S, et al. Unconventional superconductivity in magic-angle graphene superlattices. Nature, 2018, 556: 43–50

Gao Y, Cao T, Cellini F, et al. Ultrahard carbon film from epitaxial two-layer graphene. Nat Nanotech, 2018, 13: 133–138

Li X, Cai W, An J, et al. Large-area synthesis of high-quality and uniform graphene films on copper foils. Science, 2009, 324: 1312–1314

Bae S, Kim H, Lee Y, et al. Roll-to-roll production of 30-inch graphene films for transparent electrodes. Nat Nanotech, 2010, 5: 574–578

Li X, Cai W, Colombo L, et al. Evolution of graphene growth on Ni and Cu by carbon isotope labeling. Nano Lett, 2009, 9: 4268–4272

López GA, Mittemeijer EJ. The solubility of C in solid Cu. Scripta Mater, 2004, 51: 1–5

Wu J, Wang J, Pan D, et al. Synchronous growth of high-quality bilayer Bernal graphene: from hexagonal single-crystal domains to wafer-scale homogeneous films. Adv Funct Mater, 2017, 27: 1605927

Zhou H, Yu WJ, Liu L, et al. Chemical vapour deposition growth of large single crystals of monolayer and bilayer graphene. Nat Commun, 2013, 4: 2096

Liu L, Zhou H, Cheng R, et al. High-yield chemical vapor deposition growth of high-quality large-area AB-stacked bilayer graphene. ACS Nano, 2012, 6: 8241–8249

Qi Z, Shi H, Zhao M, et al. Chemical vapor deposition growth of bernal-stacked bilayer graphene by edge-selective etching with H2O. Chem Mater, 2018, 30: 7852–7859

Wu Y, Chou H, Ji H, et al. Growth mechanism and controlled synthesis of AB-stacked bilayer graphene on Cu-Ni alloy foils. ACS Nano, 2012, 6: 7731–7738

Liu W, Kraemer S, Sarkar D, et al. Controllable and rapid synthesis of high-quality and large-area Bernal stacked bilayer graphene using chemical vapor deposition. Chem Mater, 2013, 26: 907–915

Yang C, Wu T, Wang H, et al. Copper-vapor-assisted rapid synthesis of large AB-stacked bilayer graphene domains on Cu-Ni alloy. Small, 2016, 12: 2009–2013

Yoo MS, Lee HC, Lee S, et al. Chemical vapor deposition of Bernal-stacked graphene on a Cu surface by breaking the carbon solubility symmetry in Cu foils. Adv Mater, 2017, 29: 1700753

Hao Y, Wang L, Liu Y, et al. Oxygen-activated growth and bandgap tunability of large single-crystal bilayer graphene. Nat Nanotech, 2016, 11: 426–431

Yan K, Peng H, Zhou Y, et al. Formation of bilayer Bernal graphene: layer-by-layer epitaxy via chemical vapor deposition. Nano Lett, 2011, 11: 1106–1110

Celebi K, Cole MT, Choi JW, et al. Evolutionary kinetics of graphene formation on copper. Nano Lett, 2013, 13: 967–974

Fang W, Hsu AL, Song Y, et al. Asymmetric growth of bilayer graphene on copper enclosures using low-pressure chemical vapor deposition. ACS Nano, 2014, 8: 6491–6499

Li Q, Chou H, Zhong JH, et al. Growth of adlayer graphene on Cu studied by carbon isotope labeling. Nano Lett, 2013, 13: 486–490

Chan CC, Chung WL, Woon WY. Nucleation and growth kinetics of multi-layered graphene on copper substrate. Carbon, 2018, 135: 118–124

Shen C, Yan X, Qing F, et al. Criteria for the growth of large-area adlayer-free monolayer graphene films by chemical vapor deposition. J Materiomics, 2019, 5: 463–470

Abidi IH, Liu Y, Pan J, et al. Regulating top-surface multilayer/single-crystal graphene growth by “gettering” carbon diffusion at backside of the copper foil. Adv Funct Mater, 2017, 27: 1700121

Han Z, Kimouche A, Kalita D, et al. Homogeneous optical and electronic properties of graphene due to the suppression of multilayer patches during CVD on copper foils. Adv Funct Mater, 2014, 24: 964–970

Yan Z, Liu Y, Ju L, et al. Large hexagonal bi- and trilayer graphene single crystals with varied interlayer rotations. Angew Chem Int Ed, 2014, 53: 1565–1569

Chen Q, Zhong Y, Huang M, et al. Direct growth of high crystallinity graphene from water-soluble polymer powders. 2D Mater, 2018, 5: 035001

Chen Q, Yi X, Huang M, et al. Sustained and controlled release of volatile precursors for chemical vapor deposition of graphene at atmospheric pressure. Chem Eur J, 2020, 26: 7463–7469

Liang T, Luan C, Chen H, et al. Exploring oxygen in graphene chemical vapor deposition synthesis. Nanoscale, 2017, 9: 3719–3735

Srinivasan BM, Hao Y, Hariharaputran R, et al. Oxygen-promoted chemical vapor deposition of graphene on copper: a combined modeling and experimental study. ACS Nano, 2018, 12: 9372–9380

Hao Y, Bharathi MS, Wang L, et al. The role of surface oxygen in the growth of large single-crystal graphene on copper. Science, 2013, 342: 720–723

Xu X, Zhang Z, Qiu L, et al. Ultrafast growth of single-crystal graphene assisted by a continuous oxygen supply. Nat Nanotech, 2016, 11: 930–935

Chen J, Cui M, Wu G, et al. Fast growth of large single-crystalline graphene assisted by sequential double oxygen passivation. Carbon, 2017, 116: 133–138

Ferrari AC, Basko DM. Raman spectroscopy as a versatile tool for studying the properties of graphene. Nat Nanotech, 2013, 8: 235–246

Ferrari AC, Meyer JC, Scardaci V, et al. Raman spectrum of graphene and graphene layers. Phys Rev Lett, 2006, 97: 187401

Wu R, Pan J, Ou X, et al. Concurrent fast growth of sub-centimeter single-crystal graphene with controlled nucleation density in a confined channel. Nanoscale, 2017, 9: 9631–9640

Pang J, Bachmatiuk A, Fu L, et al. Oxidation as a means to remove surface contaminants on Cu foil prior to graphene growth by chemical vapor deposition. J Phys Chem C, 2015, 119: 13363–13368

Magnuson CW, Kong X, Ji H, et al. Copper oxide as a “self-cleaning” substrate for graphene growth. J Mater Res, 2014, 29: 403–409

Chen X, Zhao P, Xiang R, et al. Chemical vapor deposition growth of 5 mm hexagonal single-crystal graphene from ethanol. Carbon, 2015, 94: 810–815

Wang ZJ, Dong J, Cui Y, et al. Stacking sequence and interlayer coupling in few-layer graphene revealed by in situ imaging. Nat Commun, 2016, 7: 13256

Wang H, Wang G, Bao P, et al. Controllable synthesis of submillimeter single-crystal monolayer graphene domains on copper foils by suppressing nucleation. J Am Chem Soc, 2012, 134: 3627–3630

Yan Z, Lin J, Peng Z, et al. Toward the synthesis of wafer-scale single-crystal graphene on copper foils. ACS Nano, 2012, 6: 9110–9117

Hernandez Y, Nicolosi V, Lotya M, et al. High-yield production of graphene by liquid-phase exfoliation of graphite. Nat Nanotech, 2008, 3: 563–568

Yi D, Jeon S, Hong SW. Selectively patterned regrowth of bilayer graphene for self-integrated electronics by sequential chemical vapor deposition. ACS Appl Mater Interfaces, 2018, 10: 40014–40023

Zou K, Zhu J. Transport in gapped bilayer graphene: the role of potential fluctuations. Phys Rev B, 2010, 82: 081407

Acknowledgements

This work was supported by China Postdoctoral Science Foundation (2018M642831), and Shenzhen Science and Technology Project JCYJ20180507183904841).

Author information

Authors and Affiliations

Contributions

Chen Q, Wang S, and Zhu H proposed the concept and conceived the experiments. Chen Q, Song Q, Yi X, Chen Q, Wu W, Huang M, and Zhao C carried out the experiments. Chen Q drafted the manuscript and all authors discussed and revised it.

Corresponding authors

Additional information

Conflict of interest

The authors declare no conflict of interest.

Supplementary information

Supporting data are available in the online version of the paper.

Qiao Chen received her BSc degree from Zhengzhou University in 2013. She obtained her PhD degree under the supervision of Prof. Hongwei Zhu in 2018 from Tsinghua University. She then worked as a postdoctoral fellow at Huazhong University of Science and Technology. Her current research interest is the design and preparation of low dimensional carbon structures by CVD.

Shun Wang received his PhD degree from the University of Minnesota in 2010. He then worked as a postdoctoral researcher at the University of Minnesota and as an associate professor at Shanghai Jiao Tong University. Currently he is a professor at Huazhong University of Science and Technology. His research interests are the electrical and optoelectronic properties of low dimensional materials.

Hongwei Zhu is a professor of the School of Materials Science and Engineering, Tsinghua University. He received his BSc degree in mechanical engineering (1998) and PhD degree in materials processing engineering (2003) from Tsinghua University. After postdoc experience in Japan and USA, he began his independent career as a faculty member at Tsinghua University (2008-present). His current research interests involve the structural design and engineering of nanomaterials for energy and environmental applications.

Rights and permissions

About this article

Cite this article

Chen, Q., Song, Q., Yi, X. et al. High-quality bilayer graphene grown on softened copper foils by atmospheric pressure chemical vapor deposition. Sci. China Mater. 63, 1973–1982 (2020). https://doi.org/10.1007/s40843-020-1394-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40843-020-1394-3