Abstract

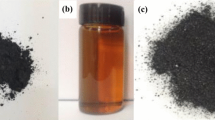

Stable aqueous carbon inks, with graphene sheets (GSs) and carbon black (CB) as conductive fillers, are prepared by a simple one-pot ball-milling method. The as-prepared composite ink with 10 wt% GSs shows optimized rheological properties (viscosity and thixotropy) for screen printing. The as-printed coatings based on the above ink are uniform and dense on a polyimide substrate, and exhibit a sandwich-type conductive three dimensional network at the microscale. The resistivity of the typical composite coating is as low as 0.23±0.01 Ω cm (92±4 Ω sq−1, 25 µm), which is 30% as that of a pure CB coating (0.77±0.01 Ω cm). It is noteworthy that the resistivity decreases to 0.18±0.01 Ω cm (72±4 Ω sq−1, 25 µm) after a further rolling compression. The coating exhibits good mechanical flexibility, and the resistance slightly increases by 12% after 3000 bending cycles. With the CB/GSs composite coatings as a flexible conductor, fascinating luminescent bookmarks and membrane switches were fabricated, demonstrating the tremendous potential of these coatings in the commercial production of flexible electronics and devices.

摘要

本文以石墨烯和炭黑作为导电填料, 通过一步球磨法制备了高导电的水性碳系油墨. 当石墨烯质量分数为10%时, 复合油墨具有最优的流变学性能; 在丝网印刷中, 该油墨在聚酰亚胺基底上形成均匀致密的涂层. 在微观上, 涂层具有夹层三维网络结构, 电阻率为0.23±0.01 Ω cm (92±4 Ω sq−1, 25 μm), 是纯炭黑涂层电阻率(0.77±0.01 Ω cm)的30%. 辊压处理后, 电阻率降至0.18±0.01 Ω cm (72±4 Ω sq−1, 25 μm), 且涂层具有良好的机械柔性, 经过3000次循环弯折试验后电阻仅增加12%. 最后, 我们将石墨烯/炭黑复合涂层作为柔性导体, 成功组装了发光书签和薄膜开关, 表明该涂层在柔性电子器件大规模生产中具有巨大的潜力.

Similar content being viewed by others

References

Singh R, Singh E, Nalwa HS. Inkjet printed nanomaterial based flexible radio frequency identification (RFID) tag sensors for the internet of nano things. RSC Adv, 2017, 7: 48597–48630

Wood V, Panzer MJ, Chen J, et al. Inkjet-printed quantum dot-polymer composites for full-color AC-driven displays. Adv Mater, 2009, 21: 2151–2155

Wu B, Zhang X, Huang B, et al. High-performance wireless ammonia gas sensors based on reduced graphene oxide and nano-silver ink hybrid material loaded on a patch antenna. Sensors, 2017, 17: 2070

Cinti S, Arduini F. Graphene-based screen-printed electrochemical (bio)sensors and their applications: Efforts and criticisms. Biosens Bioelectron, 2017, 89: 107–122

Secor EB, Dos Santos MH, Wallace SG, et al. Tailoring the porosity and microstructure of printed graphene electrodes via polymer phase inversion. J Phys Chem C, 2018, 122: 13745–13750

Secor EB, Gao TZ, Dos Santos MH, et al. Combustion-assisted photonic annealing of printable graphene inks via exothermic binders. ACS Appl Mater Interfaces, 2017, 9: 29418–29423

Naik AR, Kim JJ, Usluer Ö, et al. Direct printing of graphene electrodes for high-performance organic inverters. ACS Appl Mater Interfaces, 2018, 10: 15988–15995

Sirringhaus H, Kawase T, Friend RH, et al. High-resolution inkjet printing of all-polymer transistor circuits. Science, 2000, 290: 2123–2126

Huang X, Leng T, Zhang X, et al. Binder-free highly conductive graphene laminate for low cost printed radio frequency applications. Appl Phys Lett, 2015, 106: 203105

Huang X, Leng T, Zhu M, et al. Highly flexible and conductive printed graphene for wireless wearable communications applications. Sci Rep, 2016, 5: 18298

Tran TS, Dutta NK, Choudhury NR. Graphene inks for printed flexible electronics: Graphene dispersions, ink formulations, printing techniques and applications. Adv Colloid Interface Sci, 2018, 261: 41–61

Kamyshny A, Magdassi S. Conductive nanomaterials for printed electronics. Small, 2014, 10: 3515–3535

Secor EB, Gao TZ, Islam AE, et al. Enhanced conductivity, adhesion, and environmental stability of printed graphene inks with nitrocellulose. Chem Mater, 2017, 29: 2332–2340

Hu G, Kang J, Ng LWT, et al. Functional inks and printing of two-dimensional materials. Chem Soc Rev, 2018, 47: 3265–3300

Barragán-Iglesias P, Lou TF, Bhat VD, et al. Inhibition of poly(A)-binding protein with a synthetic RNA mimic reduces pain sensitization in mice. Nat Commun, 2018, 9: 10–38

Zhao J, Song M, Wen C, et al. Microstructure-tunable highly conductive graphene-metal composites achieved by inkjet printing and low temperature annealing. J Micromech Microeng, 2018, 28: 035006

Magdassi S, Grouchko M, Kamyshny A. Copper nanoparticles for printed electronics: Routes towards achieving oxidation stability. Materials, 2010, 3: 4626–4638

Rösch R, Tanenbaum DM, Jørgensen M, et al. Investigation of the degradation mechanisms of a variety of organic photovoltaic devices by combination of imaging techniques—the ISOS-3 inter-laboratory collaboration. Energy Environ Sci, 2012, 5: 6521–6540

Su C, Bu X, Xu L, et al. A novel LiFePO4/graphene/carbon composite as a performance-improved cathode material for lithium-ion batteries. Electrochim Acta, 2012, 64: 190–195

Murr LE. Nanoparticulate materials in antiquity: The good, the bad and the ugly. Mater Charact, 2009, 60: 261–270

Khandavalli S, Park JH, Kariuki NN, et al. Rheological investigation on the microstructure of fuel cell catalyst inks. ACS Appl Mater Interfaces, 2018, 10: 43610–43622

Youssry M, Madec L, Soudan P, et al. Non-aqueous carbon black suspensions for lithium-based redox flow batteries: rheology and simultaneous rheo-electrical behavior. Phys Chem Chem Phys, 2013, 15: 14476–14486

Jo Y, Kim JY, Kim SY, et al. 3D-printable, highly conductive hybrid composites employing chemically-reinforced, complex dimensional fillers and thermoplastic triblock copolymers. Nanoscale, 2017, 9: 5072–5084

Youssry M, Kamand FZ, Magzoub MI, et al. Aqueous dispersions of carbon black and its hybrid with carbon nanofibers. RSC Adv, 2018, 8: 32119–32131

Latil S, Henrard L. Electric field effect in atomically thin carbon films. Science, 2004, 306: 666–669

Raccichini R, Varzi A, Passerini S, et al. The role of graphene for electrochemical energy storage. Nat Mater, 2014, 14: 271–279

Hernandez Y, Lotya M, Rickard D, et al. Measurement of multi-component solubility parameters for graphene facilitates solvent discovery. Langmuir, 2010, 26: 3208–3213

Novoselov KS, Fal’ko VI, Colombo L, et al. A roadmap for graphene. Nature, 2012, 490: 192–200

Arapov K, Jaakkola K, Ermolov V, et al. Graphene screen-printed radio-frequency identification devices on flexible substrates. Phys Status Solidi RRL, 2016, 10: 812–818

Arapov K, Rubingh E, Abbel R, et al. Conductive screen printing inks by gelation of graphene dispersions. Adv Funct Mater, 2016, 26: 586–593

Hyun WJ, Secor EB, Hersam MC, et al. High-resolution patterning of graphene by screen printing with a silicon stencil for highly flexible printed electronics. Adv Mater, 2015, 27: 109–115

Zabek D, Seunarine K, Spacie C, et al. Graphene ink laminate structures on poly(vinylidene difluoride) (PVDF) for pyroelectric thermal energy harvesting and waste heat recovery. ACS Appl Mater Interfaces, 2017, 9: 9161–9167

Xu Y, Hennig I, Freyberg D, et al. Inkjet-printed energy storage device using graphene/polyaniline inks. J Power Sources, 2014, 248: 483–488

Wang R, Li W, Liu L, et al. Carbon black/graphene-modified aluminum foil cathode current collectors for lithium ion batteries with enhanced electrochemical performances. J Electroanal Chem, 2019, 833: 63–69

Cai J, Hu N, Wu L, et al. Preparing carbon black/graphene/PVDF-HFP hybrid composite films of high piezoelectricity for energy harvesting technology. Compos Part A-Appl Sci Manufact, 2019, 121: 223–231

Ji A, Chen Y, Wang X, et al. Inkjet printed flexible electronics on paper substrate with reduced graphene oxide/carbon black ink. J Mater Sci-Mater Electron, 2018, 29: 13032–13042

Chen Y, Zhou L, Wei J, et al. Direct ink writing of flexible electronics on paper substrate with graphene/polypyrrole/carbon black ink. J Elec Materi, 2019, 48: 3157–3168

Hua C, Li X, Shen L, et al. Influence of co-solvent hydroxyl group number on properties of water-based conductive carbon pastes. Particuology, 2017, 33: 35–41

Lin X, Zhang K, Li K, et al. Dependence of rheological behaviors of polymeric composites on the morphological structure of carbonaceous nanoparticles. J Appl Polym Sci, 2018, 135: 46416

Chakraborty G, Gupta A, Pugazhenthi G, et al. Facile dispersion of exfoliated graphene/PLA nanocomposites via in situ poly-condensation with a melt extrusion process and its rheological studies. J Appl Polym Sci, 2018, 135: 46476

Mao T, Tang Y, Zhang Y, et al. Carbon nanotubes/polyaniline nanocomposite coatings: Preparation, rheological behavior, and their application in paper surface treatment. J Appl Polym Sci, 2018, 135: 46329

Eom Y, Kim F, Yang SE, et al. Rheological design of 3D printable all-inorganic inks using BiSbTe-based thermoelectric materials. J Rheology, 2019, 63: 291–304

Wang S, Zhong Y, Fang H. Deformation characteristics of a single droplet driven by a piezoelectric nozzle of the drop-on-demand inkjet system. J Fluid Mech, 2019, 869: 634–645

Kitsomboonloha R, Morris SJS, Rong X, et al. Femtoliter-scale patterning by high-speed, highly scaled inverse gravure printing. Langmuir, 2012, 28: 16711–16723

Taroni M, Breward CJW, Howell PD, et al. Boundary conditions for free surface inlet and outlet problems. J Fluid Mech, 2012, 708: 100–110

Su FY, You C, He YB, et al. Flexible and planar graphene conductive additives for lithium-ion batteries. J Mater Chem, 2010, 20: 9644–9650

Ruschau GR, Yoshikawa S, Newnham RE. Resistivities of conductive composites. J Appl Phys, 1992, 72: 953–959

Hof F, Kampioti K, Huang K, et al. Conductive inks of graphitic nanoparticles from a sustainable carbon feedstock. Carbon, 2017, 111: 142–149

Jason Jan C, Walton MD, McConnell EP, et al. Carbon black thin films with tunable resistance and optical transparency. Carbon, 2006, 44: 1974–1981

Lu H, Liu Y, Gou J, et al. Electroactive shape-memory polymer nanocomposites incorporating carbon nanofiber paper. Int J Smart Nano Mater, 2010, 1: 2–12

Pahalagedara LR, Siriwardane IW, Tissera ND, et al. Carbon black functionalized stretchable conductive fabrics for wearable heating applications. RSC Adv, 2017, 7: 19174–19180

Jimenez MJM, de Oliveira RF, Bufon CCB, et al. Enhanced mobility and controlled transparency in multilayered reduced graphene oxide quantum dots: a charge transport study. Nanotechnology, 2019, 30: 275701

Yu S, Wang X, Xiang H, et al. 1-D polymer ternary composites: Understanding materials interaction, percolation behaviors and mechanism toward ultra-high stretchable and super-sensitive strain sensors. Sci China Mater, 2019, 62: 995–1004

Zhang Q, Xu Y, Yang Y, et al. Conductive mechanism of carbon black/polyimide composite films. J Polymer Eng, 2018, 38: 147–156

Acknowledgements

This research was supported by the Scientific and Technological Key Project of Shanxi Province (MC2016-04 and MC2016-08), Natural Science Foundation of Shanxi Province (201801D221156), DNL Cooperation Fund of CAS (DNL180308), Science and Technology Service Network Initiative of CAS (KFJ-STS-ZDTP-068), and Youth Innovation Promotion Association of CAS.

Author information

Authors and Affiliations

Contributions

Author contributions Yang X, Li XM and Chen CM conceived the project. Yang X performed the preparation of conductive inks, printing of patterns, characterization of inks and patterns as well as the demonstration of luminescent and membrance switch. Li XM set up the mechanical flexibility equipment. Kong QQ, Liu Z and Xie LJ supervised the project. Jia H contributed the photographs. Yang X, Li XM, Chen JP and Liu YZ wrote and amended the paper.

Corresponding author

Ethics declarations

Conflict of interest The authors declare no conflict of interest.

Additional information

Xiao Yang received her Bachelor of Engineering degree from Shanxi University of Science and Technology in 2017. She is currently pursuing a Master’s degree under the supervision of Prof. Chengmeng Chen at the Institute of Coal Chemistry, Chinese Academy of Sciences. Her research involves the design and synthesis of conductive inks for flexible printed electronics applications.

Chengmeng Chen received his PhD in materials science in 2012 from the Institute of Coal Chemistry, Chinese Academy of Sciences. Currently, he is a professor and Vice Director of the Key Laboratory of Carbon Materials, Institute of Coal Chemistry, Chinese Academy of Sciences. Dr. Chen is committed to the research and development of advanced carbon materials and energy storage devices.

Supporting Information

40843_2019_1210_MOESM1_ESM.pdf

One-Pot Ball-Milling Preparation of Graphene/Carbon Black Aqueous Inks for Highly Conductive and Flexible Printed Electronics

Rights and permissions

About this article

Cite this article

Yang, X., Li, XM., Kong, QQ. et al. One-pot ball-milling preparation of graphene/carbon black aqueous inks for highly conductive and flexible printed electronics. Sci. China Mater. 63, 392–402 (2020). https://doi.org/10.1007/s40843-019-1210-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40843-019-1210-3