Abstract

Over the past several decades, great endeavors have been devoted to superhard materials research, among which two topics are of central focus. One is to understand hardness microscopically and reveal the controlling factors for superhardness, which can be used to guide the design of novel superhard crystals; the other is to synthesize superhard materials with enhanced comprehensive performance (i.e., hardness, fracture toughness, and thermal stability), with the ambition to synthesize materials harder than natural diamond. We proposed a microscopic understanding of the indentation hardness as the combined resistance of chemical bonds in a material to indentation, and established a microscopic hardness model for covalent and polar covalent crystals, which was further generalized to polycrystalline materials. Guided by the polycrystalline hardness model, we successfully synthesized nanotwinned cubic boron nitride and diamond bulks under high pressure and high temperature. These materials exhibit simultaneous improvement of hardness, fracture toughness, and thermal stability, designating a new direction for superhard materials research.

摘要

半个世纪以来, 超硬材料研究领域一直存在两个重要难题亟待解决: (1) 硬度的微观理论或超硬材料的设计原理; (2) 合成出综合性能(硬度、 韧性和热稳定性)更加优异的新型超硬材料, 尤其是实现人工材料比天然金刚石更硬这一梦想. 在过去的十多年里, 我们提出了一个基本假设—微观上硬度等于晶体单位面积中化学键对压入的综合阻抗, 由此建立了共价和极性共价晶体硬度的微观模型, 实现了晶体硬度的定量预测. 随后, 我们将晶体硬度的微观模型推广至多晶固体, 建立了多晶共价材料硬度的理论模型. 最近, 以多晶硬度模型为指导, 我们在高温高压条件下分别合成出纳米孪晶结构的立方氮化硼和金刚石块材. 与单晶材料相比, 纳米孪晶立方氮化硼和金刚石的硬度、 韧性和热稳定性均得到明显改善, 为发展高性能超硬材料探索出一条崭新的途径.

Similar content being viewed by others

References

Haines J, Leger JM, Bocquillon G. Synthesis and design of super-hard materials. Annu Rev Mater Res, 2001, 31: 1–23

Man-made diamonds. Chem Eng News, 1955, 33: 718

Wentorf RH. Cubic form of boron nitride. J Chem Phys, 1957, 26: 956–956

Gilman JJ, Cumberland RW, Kaner RB. Design of hard crystals. Int J Refract Met Hard Mater, 2006, 24: 1–5

Ivanovskii AL. The search for novel superhard and incompressible materials on the basis of higher borides of s, p, d metals. J Superhard Mater, 2011, 33: 73–87

Riedel R. Novel ultrahard materials. Adv Mater, 1994, 6: 549–560

Veprek S. Recent search for new superhard materials: go nano! J Vac Sci Technol A, 2013, 31: 050822

Kaner RB, Gilman JJ, Tolbert SH. Designing superhard materials. Science, 2005, 308: 1268–1269

Veprek S. The search for novel, superhard materials. J Vac Sci Technol A, 1999, 17: 2401–2420

Brazhkin VV, Lyapin AG, Hemley RJ. et al. Harder than diamond: dreams and reality. Philos Mag A, 2002, 82: 231–253

Meyer E. Analysis of hardness examination and hardness. Zt Vereins Deutscher Ingenieure, 1908, 52: 645–654

Gilman JJ. The Science of Hardness Testing and Its Research Applications. Metals Park: American Society for Metals, 1973

Liu AY, Cohen ML. Prediction of new low compressibility solids. Science, 1989, 245: 841–842

Teter DM. Computational alchemy: the search for new superhard materials. MRS Bull, 1998, 23: 22–27

Chen XQ, Niu H, Li D, et al. Modeling hardness of polycrystalline materials and bulk metallic glasses. Intermetallics, 2011, 19: 1275–1281

Gao FM, He JL, Wu ED, et al. Hardness of covalent crystals. Phys Rev Lett, 2003, 91: 015502

He JL, Wu ED, Wang HT, et al. Ionicities of boron-boron bonds in B12 icosahedra. Phys Rev Lett, 2005, 94: 015504

Guo X, Li L, Liu Z, et al. Hardness of covalent compounds: roles of metallic component and d valence electrons. J Appl Phys, 2008, 104: 023503

Tian Y, Xu B, Zhao Z, et al. Microscopic theory of hardness and design of novel superhard crystals. Int J Refract Met Hard Mater, 2012, 33: 93–106

Simunek A, Vackar J. Hardness of covalent and ionic crystals: first-principle calculations. Phys Rev Lett, 2006, 96: 085501

Li KY, Wang XT, Zhang FF, et al. Electronegativity identification of novel superhard materials. Phys Rev Lett, 2008, 100: 235504

Zhao Y, He DW, Daemen LL, et al. Superhard B-C-N materials synthesized in nanostructured bulks. J Mater Res, 2002, 17: 3139–3145

Solozhenko VL, Gregoryanz E. Synthesis of superhard materials. Mater Today, 2005, 8: 44–51

Solozhenko VL, Andrault D, Fiquet G, et al. Synthesis of superhard cubic BC2N. Appl Phys Lett, 2001, 78: 1385–1387

Solozhenko VL, Kurakevych OO, Andrault D, et al. Ultimate metastable solubility of boron in diamond: synthesis of superhard diamondlike BC5. Phys Rev Lett, 2009, 102: 015506

Solozhenko VL, Kurakevych OO, Oganov AR, et al. On the hardness of a new boron phase, orthorhombic γ-B28. J Superhard Mater, 2008, 30: 428–429

He DW, Zhao YS, Daemen L, et al. Boron suboxide: as hard as cubic boron nitride. Appl Phys Lett, 2002, 81: 643–645

Levine JB, Tolbert SH, Kaner RB, et al. Advancements in the search for superhard ultra-incompressible metal borides. Adv Funct Mater, 2009, 19: 3519–3533

Gu Q, Krauss G, Steurer W, et al. Transition metal borides: superhard versus ultra-incompressihle. Adv Mater, 2008, 20: 3620–3626

Chung HY, Weinberger MB, Levine JB, et al. Synthesis of ultra-incompressible superhard rhenium diboride at ambient pressure. Science, 2007, 316: 436–439

Crowhurst JC, Goncharov AF, Sadigh B, et al. Synthesis and characterization of the nitrides of platinum and iridium. Science, 2006, 311: 1275–1278

Cumberland RW, Weinberger MB, Gilman JJ, et al. Osmium diboride, an ultra-incompressible, hard material. J Am Chem Soc, 2005, 127: 7264–7265

Ono S, Kikegawa T, Ohishi Y, et al. A high-pressure and high-temperature synthesis of platinum carbide. Solid State Commun, 2005, 133: 55–59

Qin J, He D, Wang J, et al. Is rhenium diboride a superhard material? Adv Mater, 2008, 20: 4780–4783

Young AF, Sanloup C, Gregoryanz E, et al. Synthesis of novel transition metal nitrides IrN2 and OsN2. Phys Rev Lett, 2006, 96: 155501

Gou H, Dubrovinskaia N, Bykova E, et al. Discovery of a superhard iron tetraboride superconductor. Phys Rev Lett, 2013, 111: 157002

Dubrovinskaia N, Dubrovinsky L, Solozhenko VL, et al. Comment on “Synthesis of ultra-incompressible superhard rhenium diboride at ambient pressure”. Science, 2007, 318: 1550–1550

Li B, Sun H, Chen C, et al. First-principles calculation of the indentation strength of FeB4. Phys Rev B, 2014, 90: 014106

Zhang M, Lu M, Du Y, et al. Hardness of FeB4: density functional theory investigation. J Chem Phys, 2014, 140: 174505

Irifune T, Kurio A, Sakamoto S, et al. Ultrahard polycrystalline diamond from graphite. Nature, 2003, 421: 599–600

Dubrovinskaia N, Solozhenko VL, Miyajima N, et al. Superhard nanocomposite of dense polymorphs of boron nitride: noncarbon material has reached diamond hardness. Appl Phys Lett, 2007, 90: 101912

Solozhenko VL, Kurakevych OO, Le Godec Y, et al. Creation of nanostuctures by extreme conditions: high-pressure synthesis of ultrahard nanocrystalline cubic boron nitride. Adv Mater, 2012, 24: 1540–1544

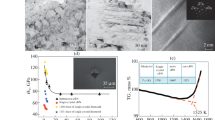

Tian Y, Xu B, Yu D, et al. Ultrahard nanotwinned cubic boron nitride. Nature, 2013, 493: 385–388

Huang Q, Yu D, Xu B, et al. Nanotwinned diamond with unprecedented hardness and stability. Nature, 2014, 510: 250–253

Pugh SF. Relations between the elastic moduli and the plastic properties of polycrystalline pure metals. Philos Mag, 1954, 45: 823–843

Chen XQ, Niu H, Franchini C, et al. Hardness of T-carbon: density functional theory calculations. Phys Rev B, 2011, 84: 121405

Nix WD, Gao H. Indentation size effects in crystalline materials: a law for strain gradient plasticity. J Mech Phys Solids, 1998, 46: 411–425

Gilman JJ. Flow of covalent solids at low-temperatures. J Appl Phys, 1975, 46: 5110–5113

Phillips JC. Ionicity of chemical bond in crystals. Rev Mod Phys, 1970, 42: 317–356

Siethoff H. Homopolar band gap and thermal activation parameters of plasticity of diamond and zinc-blende semiconductors. J Appl Phys, 2000, 87: 3301–3305

Pauling L. The Nature of the Chemical Bond and the Structure of Molecules and Crystals: an Introduction to Modern Structural Chemistry. New York: Cornell University Press, 1960

Liu HY, Li QA, Zhu L, et al. Superhard polymorphs of diamond-like BC7. Solid State Commun, 2011, 151: 716–719

Liu HY, Li QA, Zhu L, et al. Superhard and superconductive polymorphs of diamond-like BC3. Phys Lett A, 2011, 375: 771–774

Li Q, Chen WJ, Xia Y, et al. Superhard phases of B2O: an isoelectronic compound of diamond. Diamond Relat Mater, 2011, 20: 501–504

Li QA, Wang H, Tian YJ, et al. Superhard and superconducting structures of BC5. J Appl Phys, 2010, 108: 023507

Fan XF, Wu HY, Shen ZX, et al. A first-principle study on the structure, stability and hardness of cubic BC2N. Diamond Relat Mater, 2009, 18: 1278–1282

Guo X, Liu Z, Luo X, et al. Theoretical hardness of the cubic BC2N. Diamond Relat Mater, 2007, 16: 526–530

Li Y, Li Q, Ma Y, et al. B2CO: a potential superhard material in the B-C-O system. Europhys Lett, 2011, 95: 66006

Li DX, Yu DL, He JL, et al. First-principle calculation on structures and properties of diamond-like B3C10N3 compound. J Alloys Compd, 2009, 481: 855–857

Zhao Z, Cui L, Wang LM, et al. Bulk Re2C: crystal structure, hardness, and ultra-incompressibility. Cryst Growth Des, 2010, 10: 5024–5026

Wang ZH, Kuang XY, Zhong MM, et al. Pressure-induced structural transition of OsN2 and effect of metallic bonding on its hardness. Europhys Lett, 2011, 95: 66005

Shao X. Prediction of a low-dense BC2N phase. Chin Phys Lett, 2011, 28: 057101

Wang H, Li Q, Wang H, et al. Design of superhard ternary compounds under high pressure: SiC2N4 and Si2CN4. J Phys Chem C, 2010, 114: 8609–8613

Hu M, Zhao Z, Tian F, et al. Compressed carbon nanotubes: a family of new multifunctional carbon allotropes. Sci Rep, 2013, 3: 1331

Zhao Z, Tian F, Dong X, et al. Tetragonal allotrope of group 14 elements. J Am Chem Soc, 2012, 134: 12362–12365

Zhao Z, Xu B, Zhou XF, et al. Novel superhard carbon: C-centered orthorhombic C8. Phys Rev Lett, 2011, 107: 215502

Xiong M, Fan CZ, Zhao ZS, et al. Novel three-dimensional boron nitride allotropes from compressed nanotube bundles. J Mater Chem C, 2014, 2: 7022–7028

Amsler M, Flores-Livas J, Lehtovaara L, et al. Crystal structure of cold compressed graphite. Phys Rev Lett, 2012, 108: 065501

Baburin IA, Proserpio DM, Saleev VA, et al. From zeolite nets to sp3 carbon allotropes: a topology-based multiscale theoretical study. Phys Chem Chem Phys, 2015, 17: 1332–1338

Bu H, Zhao M, Dong W, et al. A metallic carbon allotrope with superhardness: a first-principles prediction. J Mater Chem C, 2014, 2: 2751–2757

Zhang M, Liu H, Du Y, et al. Orthorhombic C32: a novel superhard sp3 carbon allotrope. Phys Chem Chem Phys, 2013, 15: 14120–14125

Hu M, Huang Q, Zhao Z, et al. Superhard and high-strength yne-diamond semimetals. Diamond Relat Mater, 2014, 46: 15–20

Xu B, Tian YJ. Microscopic models of materials mechanical properties. Prog Phys, 2014, 34: 191–201

Gilman JJ. Chemistry and Physics of Mechanical Hardness. Hoboken: John Wiley & Sons, 2009

Tse JS. Intrinsic hardness of crystalline solids. J Superhard Mater, 2010, 32: 177–191

Chaudhri MM, Lim YY. Harder than diamond? Just fiction. Nat Mater, 2005, 4: 4

Zhang X, Wang Y, Lv J, et al. First-principles structural design of superhard materials. J Chem Phys, 2013, 138: 114101

Hall EO. The deformation and ageing of mild steel: III. discussion of results. Proc Phys Soc London B, 1951, 64: 747–753

Petch NJ. The cleavage strength of polycrystals. J Iron Steel Ins, 1953, 174: 25–28

Tse JS, Klug DD, Gao F. Hardness of nanocrystalline diamonds. Phys Rev B, 2006, 73: 140102

Sumiya H, Irifune T. Hardness and deformation microstructures of nano-polycrystalline diamonds synthesized from various carbons under high pressure and high temperature. J Mater Res, 2007, 22: 2345–2351

Lu L, Chen X, Huang X, et al. Revealing the maximum strength in nanotwinned copper. Science, 2009, 323: 607–610

Lu L, Shen Y, Chen X, et al. Ultrahigh strength and high electrical conductivity in copper. Science, 2004, 304: 422–426

Sumiya H, Uesaka S, Satoh S, et al. Mechanical properties of high purity polycrystalline cBN synthesized by direct conversion sintering method. J Mater Sci, 2000, 35: 1181–1186

Yan CS, Mao HK, Li W, et al. Ultrahard diamond single crystals from chemical vapor deposition. Phys Status Solidi A, 2004, 201: R25–R27

Lammer A. Mechanical properties of polycrystalline diamonds. Mater Sci Technol, 1988, 4: 949–955

Sussmann RS, Pickles CSJ, Brandon JR, et al. CVD diamond windows for infrared synchrotron applications. Il Nuovo Cimento D, 1998, 20: 503–525

Dubrovinskaia N, Dub S, Dubrovinsky L, et al. Superior wear resistance of aggregated diamond nanorods. Nano Lett, 2006, 6: 824–826

Lu K, Lu L, Suresh S, et al. Strengthening materials by engineering coherent internal boundaries at the nanoscale. Science, 2009, 324: 349–352

Brazhkin V, Dubrovinskaia N, Nicol M, et al. What does “harder than diamond” mean? Nat Mater, 2004, 3: 576–577

Chung HY, Weinberger MB, Levine JB, et al. Response to comment on “Synthesis of ultra-incompressible superhard rhenium diboride at ambient pressure”. Science, 2007, 318:1550

Brookes CA, Green P. Deformation of magnesium-oxide crystals by softer indenters and sliders. Nature Phys Sci, 1973, 246: 119–122

Brookes CA, Shaw MP. Cumulative deformation of magnesium-oxide crystals by softer sliders. Nature, 1976, 263: 760–762

Brookes EJ, Comins JD, Daniel RD, et al. A study of plastic deformation profiles of impressions in diamond. Diamond Relat Mater, 2000, 9: 1115–1119

Tian Y, Xu B, Yu D, et al. Controversy about ultrahard nanotwinned cBN. Nature, 2013, 502: E1–E2

Xu B, Tian YJ. Ultrahardness: measurement and enhancement. J Phys Chem C, In press

Luo X, Liu Z, Xu B, et al. Compressive strength of diamond from first-principles calculation. J Phys Chem C, 2010, 114: 17851–17853

Roundy D, Cohen M. Ideal strength of diamond, Si, and Ge. Phys Rev B, 2001, 64: 212103

Zhang R, Veprek S, Argon A, et al. Anisotropic ideal strengths and chemical bonding of wurtzite BN in comparison to zincblende BN. Phys Rev B, 2008, 77: 172103

Zhang RF, Sheng SH, Veprek S, et al. First principles studies of ideal strength and bonding nature of AlN polymorphs in comparison to TiN. Appl Phys Lett, 2007, 91: 031906

Umeno Y, Shiihara Y, Yoshikawa N, et al. Ideal shear strength under compression and tension in C, Si, Ge, and cubic SiC: an ab initio density functional theory study. J Phys Condens Matter, 2011, 23: 385401

Zhang RF, Legut D, Wen XD, et al. Bond deformation paths and electronic instabilities of ultraincompressible transition metal diborides: case study of OsB2 and IrB2. Phys Rev B, 2014, 90: 094115

Yip S. Nanocrystals: the strongest size. Nature, 1998, 391: 532–533

Li X, Wei Y, Lu L, et al. Dislocation nucleation governed softening and maximum strength in nano-twinned metals. Nature, 2010, 464: 877–880

Jiang K, Li Q, Fan S, et al. Nanotechnology: spinning continuous carbon nanotube yarns. Nature, 2002, 419: 801

Fan S, Chapline MG, Franklin NR, et al. Self-oriented regular arrays of carbon nanotubes and their field emission properties. Science, 1999, 283: 512–514

Wollmershauser JA, Feigelson BN, Gorzkowski EP, et al. An extended hardness limit in bulk nanoceramics. Acta Mater, 2014, 69: 9–16

Author information

Authors and Affiliations

Corresponding author

Additional information

Bo Xu is a professor of College of Materials Science and Engineering, Yanshan University. He received his PhD from University of Nebraska-Lincoln (2002). After postdoctoral work at University of Maryland, College Park, he joined the State Key Laboratory of Metastable Materials Science and Technology, Yanshan University in 2006. His research interests include superhard materials and thermoelectric materials.

Yongjun Tian is a professor of College of Materials Science and Engineering, Yanshan University. He received his PhD from Institute of Physics, Chinese Academy of Sciences, in 1994, and worked as a postdoctoral fellow in Universität Jena supported by the Humboldt Research Fellowships from 1996 to 1998. His research interests include design and synthesis of novel metastable materials.

Rights and permissions

About this article

Cite this article

Xu, B., Tian, Y. Superhard materials: recent research progress and prospects. Sci. China Mater. 58, 132–142 (2015). https://doi.org/10.1007/s40843-015-0026-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40843-015-0026-5