Abstract

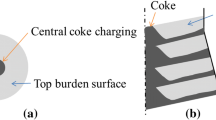

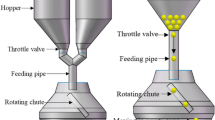

Formation of a good central chimney is integral to stable blast furnace operations, for which large sized coke, also known as centre coke, is charged in the centre of blast furnace. Internal visualization of the blast furnace has revealed that the above burden probes inside can alter the course of falling centre coke. This disturbs the central chimney shape and affects the gas flow inside, causing abnormalities. Above burden probes provide useful information regarding the top gas radial temperature profile and composition. They practically dictate furnace operational philosophies, hence their presence inside the furnace is non-questionable. The influence of their positions as well as other operating parameters like chute angle and charging time of centre coke on final heap formation is studied in detail using discrete element method (DEM) simulations. Rotating chute and above burden probe geometries are incorporated in the simulations and flow of model centre coke (derived from careful experimentation) is simulated. Material flow and heap formation is found to be better at steeper chute inclination angles at the cost of some scattering due to stiffeners located at chute bottom. Above burden probes in their original positions disrupt heap formation drastically, however moving them slightly outside enhances proper heap formation. Optimum ranges for chute angle and above burden probe repositioning are determined, and the effect of implementing these changes in blast furnace are discussed as well.

Graphical Abstract

Similar content being viewed by others

References

Narita K, Si Inaba, Shimizu M, Yamaguchi A, Kobayashi I, Ki Okimoto (1981) Burden and gas distribution considering blast furnace aerodynamics. Trans Iron Steel Inst Jpn 21(6):405–413. https://doi.org/10.2355/isijinternational1966.21.405

Takahashi H, Kawai H, Kobayashi M, Fukui T (2005) Two dimensional cold model study on unstable solid descending motion and control in blast furnace operation with low reducing agent rate. ISIJ Int 45(10):1386–1395. https://doi.org/10.2355/isijinternational.45.1386

Yu X, Shen Y (2020) Model study of central coke charging on ironmaking blast furnace performance: Effects of charing pattern and nut coke. Powder Technol 361:124–135. https://doi.org/10.1016/j.powtec.2019.10.012

Yu X, Shen Y (2019) Model study of blast furnace operation with central coke charging. Metall Mater Trans B 50:2238–2250. https://doi.org/10.1007/s11663-019-01657-2

Xu H, Wang Y, Li C, Guo H, Yan B (2023) Research on the factors affecting the formation of ore-free zone at blast furnace throat based on DEM. Processes 11(3):967. https://doi.org/10.3390/pr11030967

Kou M, Zeng W, Zhang Z, She X, Zhang T, Zhao B et al (2022) Central coke charging and its effect on coke collapse at the throat of blast furnace by DEM simulation. Powder Technol 408:117784. https://doi.org/10.1016/j.powtec.2022.117784

Chakrabarty A, Basu S, Nag S, Ghosh U, Patra M (2021) Model study of centre coke charging in blast furnace through DEM simulations. ISIJ Int 61(3):782–791. https://doi.org/10.2355/isijinternational.ISIJINT-2020-498

Primetals Technologies (2023) Above Burden Probe - Temperature and Gas Monitoring. Accessed on June 30th. https://www.primetals.com/fileadmin/user_upload/content/01_portfolio/1_ironmaking/blast-furnace/ABOVE_BURDEN_PROBE_-_TEMPERATURE_AND_GAS_MONITORING.pdf

Ueda S, Natsui S, Nogami H, Yagi J, Ariyama T (2010) Recent progress and future perspective on mathematical modeling of blast furnace. ISIJ Int 50(7):914–923. https://doi.org/10.2355/isijinternational.50.914

Ariyama T, Natsui S, Kon T, Ueda S, Kikuchi S, Nogami H (2014) Recent progress on advanced blast furnace mathematical models based on discrete method. ISIJ Int 54(7):1457–1471. https://doi.org/10.2355/isijinternational.54.1457

Abhale PB, Viswanathan NN, Saxén H (2020) Numerical modelling of blast furnace - evolution and recent trends. Miner Process Extr Metall 129(2):166–183. https://doi.org/10.1080/25726641.2020.1733357

Chen J, Zuo H, Xue Q, Wang J (2022) A review of burden distribution models of blast furnace. Powder Technol 398:117055. https://doi.org/10.1016/j.powtec.2021.117055

Roeplal R, Pang Y, Adema A, van der Stel J, Schott D (2023) Modelling of phenomena affecting blast furnace burden permeability using the Discrete Element Method (DEM) - a review. Powder Technol 415:118161. https://doi.org/10.1016/j.powtec.2022.118161

Cundall PA, Strack ODL (1979) A discrete numerical model for granular assemblies. Géotechnique 29(1):47–65. https://doi.org/10.1680/geot.1979.29.1.47

Altair EDEM (2023) Introduction to Altair EDEM and physics models. Accessed on February 8th. https://www.altair.com/resource/introduction-to-altair-edem-and-physics-models

Li C, Honeyands T, O’Dea D, Moreno-Atanasio R (2017) The angle of repose and size segregation of iron ore granules: DEM analysis and experimental investigation. Powder Technol 320:257–272. https://doi.org/10.1016/j.powtec.2017.07.045

Chibwe D (2019) Optimised burden delivery for blast operations. University of Newcastle, Australia

Liu S, Zhou Z, Dong K, Yu A, Pinson D, Tsalapatis J (2015) Numerical investigation of burden distribution in a blast furnace. Steel Res Int 86(6):651–661. https://doi.org/10.1002/srin.201400360

Wei H, Nie H, Li Y, Saxén H, He Z, Yu Y (2020) Measurement and simulation validation of DEM parameters of pellet, sinter and coke particles. Powder Technol 364:593–603. https://doi.org/10.1016/j.powtec.2020.01.044

Yu Y, Saxen H (2012) Effect of DEM parameters on the simulated inter-particle percolation of pellets into coke during burden descent in the blast furnace. ISIJ Int 52(5):788–796. https://doi.org/10.1016/isijinternational.52.788

Barrios GKP, de Carvalho RM, Kwade A, Tavares LM (2013) Contact parameter estimation for DEM simulation of iron ore pellet handling. Powder Technol 248:84–93. https://doi.org/10.1016/j.powtec.2013.01.063

Degrassi G, Parussini L, Boscolo M, Petronelli N, Dimastromatteo V (2021) Discrete element simulation of the charge in the hopper of a blast furnace, calibrating the parameters through an optimization algorithm. SN App Sci 3:242. https://doi.org/10.1007/s42452-021-04254-8

Acknowledgements

The authors would like to thank all people involved during installation of the thermal-sensor based camera from operations, mechanical maintenance and electrical maintenance teams as well as design and IT teams of Tata Steel. Their efforts led to successful implementation of the same and provided us with eye-opening insights that would otherwise be very difficult to visualize in a running furnace.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

The contributing editor for this article was Sharif Jahanshahi.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chakrabarty, A., Ohri, R., Chaudhari, U. et al. Influence of Above Burden Probes in Blast Furnace on Centre Coke Charging and Subsequent Operational Stability. J. Sustain. Metall. 9, 1790–1802 (2023). https://doi.org/10.1007/s40831-023-00765-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40831-023-00765-3