Abstract

This research focused on investigating the properties and phase transition of ilmenite ore with various carbon reductants by performing a carbothermal reduction, followed by a hydrogen reduction (Ar:H2) at 900–1000 °C to extract rutile from the ore. To comprehend the impact of the carbon structure and characteristics on the reduction performance and incorporate a thermodynamic assessment during reduction reactions, two distinct carbon reductants: graphite (GI) and renewable carbon from palm char (PI), were selected. The phase transitions and reduced samples were examined using both qualitative and quantitative X-ray diffraction. The results revealed that ilmenite ore transformed into pseudobrookite ferrous (FeTi2O5), titanium trioxide (Ti3O5), rutile (TiO2), and iron (Fe) after carbothermal reduction at 1550 °C where brookite (TiO2) and anatase (TiO2) peaks were diminished. As the temperature rose during the secondary reduction by hydrogen, the reduction reaction sequenced as follows: FeTi2O5 → Ti3O5 → Ti2O3 → TiO2 and Fe. Due to the carbon structure and superior characteristics, the reduced PI demonstrated a greater degree of TiO2 reduction (81.8%) than the reduced GI (74.8%) at the highest reduction temperature of 1000 °C. In the early and middle stages of the reaction at high temperatures, the carbothermal reduction of ilmenite ore with solid carbon and CO participated and produced rutile, iron, and Ti3O5, whereas, in the latter stages, rutile, iron, and Ti2O3 are mostly formed when reduced by hydrogen. In conclusion, employing palm char with hydrogen atmosphere to extract pure rutile from ilmenite ore might be accomplished by using these proposed methods.

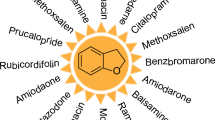

Graphical Abstract

Similar content being viewed by others

References

Mohammed AI, Yunos NFM, Idris MA et al (2022) Mineralogical characterizations of Langkawi ilmenite ore for carbothermal reduction. Int J Nanoelectron Mater 15:1–8

Saidin HS, Salim SAS, Baharun N et al (2014) An assessment of the carbothermal reduction of Malaysian ilmenite by statistical design. Adv Mater Res. https://doi.org/10.4028/www.scientific.net/AMR.858.221

Schlender P, Adam AEW (2017) Combined carboreduction-iodination reaction of TiO2 and FeTiO3 as the basic step toward a shortened titanium production process. Ind Eng Chem Res. https://doi.org/10.1021/acs.iecr.7b01170

Nakamura K, Iida T, Nakamura N, Araike T (2017) Titanium sponge production method by Kroll process at OTC. Mater Trans. https://doi.org/10.2320/matertrans.MK201634

Ono K, Suzuki RO (2002) A new concept for producing Ti sponge: calciothermic reduction. JOM. https://doi.org/10.1007/BF02701078

Wang Y, Yuan Z, Matsuura H, Tsukihashi F (2009) Reduction extraction kinetics of titania and iron from an llmenite by H2–Ar gas mixtures. ISIJ Int. https://doi.org/10.2355/isijinternational.49.164

Dewan MAR, Zhang GQ, Ostrovski O (2011) Carbothermal reduction of ilmenite concentrates and synthetic rutile in different gas atmospheres. Trans Inst Min Metall Sect C Miner Process Extr Metall. https://doi.org/10.1179/1743285511Y.0000000001

Spencer W, Ibana D, Singh P, Nikoloski AN (2022) Effect of ilmenite properties on synthetic rutile quality. Miner Eng. https://doi.org/10.1016/j.mineng.2021.107365

Lamandasa CI, Setiawan A, Harjanto S, Rhamdhani MA (2021) Effect of adding biomass from palm kernel shell on phase transformation and microstructure during carbothermic reduction of ilmenite. Int J Technol. https://doi.org/10.14716/IJTECH.V12I6.5232

Bhalla A, Kucukkargoz CS, Eric RH (2017) Solid-state reduction of an ilmenite concentrate with carbon. J South African Inst Min Metall. https://doi.org/10.17159/2411-9717/2017/v117n5a2

Man Y, Feng JX, Li FJ et al (2014) Influence of temperature and time on reduction behavior in iron ore-coal composite pellets. Powder Technol. https://doi.org/10.1016/j.powtec.2014.02.039

Galgali RK, Ray HS, Chakrabarti AK (1998) A study on carbothermic reduction of ilmenite ore in a plasma reactor. Metall Mater Trans B Process Metall Mater Process Sci. https://doi.org/10.1007/s11663-998-0039-5

Gou HP, Zhang GH, Chou KC (2014) Phase evolution during the carbothermic reduction process of ilmenite concentrate. Metall Mater Trans B Process Metall Mater Process Sci. https://doi.org/10.1007/s11663-014-0175-z

Tripathy M, Ranganathan S, Mehrotra SP (2012) Investigations on reduction of ilmenite ore with different sources of carbon. Trans Inst Min Metall Sect C Miner Process Extr Metall. https://doi.org/10.1179/1743285512Y.0000000007

Ming WY, Fu YZ, Cheng GZ et al (2008) Reduction mechanism of natural ilmenite with graphite. Trans Nonferrous Met Soc China. https://doi.org/10.1016/S1003-6326(08)60166-1

Sanada M, Abe K, Kurniawan A et al (2020) Low-Temperature synthesis of TiC from carbon-infiltrated, nano-porous TiO2. Metall Mater Trans B. https://doi.org/10.1007/s11663-020-01875-z

Setiawan A, Shaw M, Torpy A et al (2020) Solar carbothermic reduction of ilmenite using palm kernel shell biomass. JOM. https://doi.org/10.1007/s11837-020-04297-z

Setiawan A, Rhamdhani MA, Pownceby MI et al (2021) Kinetics and mechanisms of carbothermic reduction of weathered ilmenite using palm kernel shell biomass. J Sustain Metall. https://doi.org/10.1007/s40831-021-00457-w

Mohammed AI, Yunos NFM, Idris MA et al (2022) Phase transformations of Langkawi ilmenite ore during carbothermal reduction using palm char as renewable reductant. Chem Eng Res Des. https://doi.org/10.1016/j.cherd.2021.12.048

Yunos NFM, Chong JH, Mohamed AI, Idris MA (2020) Phase evolution during carbothermal reduction of langkawi ilmenite ore at different reaction times. Mater Sci Forum. https://doi.org/10.4028/www.scientific.net/MSF.1010.391

Hasniyati MR, Zuhailawati H, Ramakrishnan S, Hamid SARSA (2014) Mechanism and optimization of titanium carbide-reinforced iron composite formation through carbothermal reduction of hematite and anatase. J Alloys Compd. https://doi.org/10.1016/j.jallcom.2013.10.245

Zhao Y, Shadman F (1991) Reduction of ilmenite with hydrogen. Ind Eng Chem Res. https://doi.org/10.1021/ie00057a005

Dewan MAR, Zhang G, Ostrovski O (2009) Carbothermal reduction of titania in different gas atmospheres. Metall Mater Trans B. https://doi.org/10.1007/s11663-008-9205-z

Chen G, Ling Y, Li Q et al (2020) Highly efficient oxidation of Panzhihua titanium slag for manufacturing welding grade rutile titanium dioxide. J Mater Res Technol. https://doi.org/10.1016/j.jmrt.2020.05.044

Yu H, Li C, Wei K et al (2022) Effect of titanium suboxides on the reaction mechanism of hydrogen-reduced ilmenite. Int J Hydrogen Energy. https://doi.org/10.1016/j.ijhydene.2022.10.071

Sun K, Akiyama T, Takahashi R, Yagi J (1995) Hydrogen reduction of natural ilmenite in a fluidized bed. ISIJ Int. https://doi.org/10.2355/isijinternational.35.360

Gou HP, Zhang GH, Chou KC (2015) Influence of pre-oxidation on carbothermic reduction process of ilmenite concentrate. ISIJ Int. https://doi.org/10.2355/isijinternational.55.928

Si XG, Lu XG, Li CW et al (2012) Phase transformation and reduction kinetics during the hydrogen reduction of ilmenite concentrate. Int J Miner Metall Mater. https://doi.org/10.1007/s12613-012-0568-4

Qin J, Wang Y, You Z et al (2020) Carbonization and nitridation of vanadium-bearing titanomagnetite during carbothermal reduction with coal. J Mater Res Technol. https://doi.org/10.1016/j.jmrt.2020.02.053

Najmi NH, Yunos NFM, Othman NK, Idris MA (2019) The correlation between structural and reduction kinetics of carbon from agricultural waste with hematite. J Mater Res Technol. https://doi.org/10.1016/j.jmrt.2018.11.014

Yunos M, Ismail AN, Munusamy SRR et al (2021) Reaction kinetics of palm char and coke with iron oxides in EAF steelmaking slag. J Sustain Metall 7:412–426. https://doi.org/10.1007/s40831-021-00342-6

Chen G, Song Z, Chen J et al (2013) Evaluation of the reducing product of carbonthermal reduction of ilmenite ores. J Alloys Compd 577:610

Hellenbrandt M (2004) The inorganic crystal structure database (ICSD)—present and future. Crystallogr Rev 10:17–22. https://doi.org/10.1080/08893110410001664882

Suryanarayana C, Norton MG (1998) Precise lattice parameter measurements. X-Ray Diffr. https://doi.org/10.1007/978-1-4899-0148-4_6.pdf

Zhao P, Lu L, Liu X et al (2018) Error analysis and correction for quantitative phase analysis based on rietveld-internal standard method: whether the minor phases can be ignored? Crystals. https://doi.org/10.3390/cryst8030110

Altomare A, Capitelli F, Corriero N et al (2018) The rietveld refinement in the expo software: a powerful tool at the end of the elaborate crystal structure solution pathway. Crystals. https://doi.org/10.3390/cryst8050203

Kniess CT, Cardoso de Lima J, Prates PB (2005) The quantification of crystalline phases in materials: applications of Rietveld method. In: Sinter—Methods Prod. http://surl.li/jsfbq

Singh RP, Singh M, Verma G et al (2017) Structural analysis of silver doped hydroxyapatite nanopowders by Rietveld refinement. Trans Indian Inst Met. https://doi.org/10.1007/s12666-016-1019-0

Speakman SA (2010) Fundamentals of Rietveld refinement II. Refinement of a single phase the Rietveld method. Massachusets Inst Technol. http://surl.li/jsfco

Sharifah ASS, Saidin HS, Baharun N et al (2014) Microstructural study of reduced Malaysian ilmenite by carbothermal reduction and nitridation in nitrogen atmosphere. Adv Mater Res. https://doi.org/10.4028/www.scientific.net/AMR.858.265

TC, de Lima JC, BP (2012) The quantification of crystalline phases in materials: Applications of Rietveld method. In: Sintering—Methods and Products. http://surl.li/jsfdt

Sahajwalla V, Zaharia M, Mansuri I et al (2013) The power of steelmaking—harnessing high temperature reactions to transform waste into raw material resources. Iron Steel Technol 10:68–83

Kucukkaragoz CS, Eric RH (2006) Solid state reduction of a natural ilmenite. Minerals Eng. https://doi.org/10.1016/j.mineng.2005.09.015

Barnakov CN, Khokhlova GP, Malysheva VY et al (2015) X-ray diffraction analysis of the crystal structures of different graphites. Solid Fuel Chem. https://doi.org/10.3103/S0361521915010036

Franklin RE (1951) The structure of graphitic carbons. Acta Crystallogr. https://doi.org/10.1107/s0365110x51000842

Kurosaki F, Ishimaru K, Hata T et al (2003) Microstructure of wood charcoal prepared by flash heating. Carbon. https://doi.org/10.1016/S0008-6223(03)00434-2

Yunos NFM, Zaharia M, Idris MA et al (2012) Recycling agricultural waste from palm shells during electric arc furnace steelmaking. Energy Fuels. https://doi.org/10.1021/ef201184h

Mohd Yunos NF, Zaharia M, Ahmad KR et al (2011) Structural transformation of agricultural waste/coke blends and their implications during high temperature processes. ISIJ Int. https://doi.org/10.2355/isijinternational.51.1185

Lahijani P, Zainal ZA, Mohamed AR, Mohammadi M (2013) CO2 gasification reactivity of biomass char: catalytic influence of alkali, alkaline earth and transition metal salts. Bioresour Technol. https://doi.org/10.1016/j.biortech.2013.06.059

Takagi H, Maruyama K, Yoshizawa N et al (2004) XRD analysis of carbon stacking structure in coal during heat treatment. Fuel. https://doi.org/10.1016/j.fuel.2004.06.019

Subasinghe HCS, Ratnayake AS (2021) Processing of ilmenite into synthetic rutile using ball milling induced sulphurisation and carbothermic reduction. Miner Eng. https://doi.org/10.1016/j.mineng.2021.107197

Allen NS, Mahdjoub N, Vishnyakov V et al (2018) The effect of crystalline phase (anatase, brookite and rutile) and size on the photocatalytic activity of calcined polymorphic titanium dioxide (TiO2). Polym Degrad Stab. https://doi.org/10.1016/j.polymdegradstab.2018.02.008

Hanaor DAH, Sorrell CC (2011) Review of the anatase to rutile phase transformation. J Mater Sci. https://doi.org/10.1007/s10853-010-5113-0

Yang F, Hlavacek V (2000) Effective extraction of titanium from rutile by a low-temperature chloride process. AIChE J. https://doi.org/10.1002/aic.690460213

Li JG, Ishigaki T (2004) Brookite → rutile phase transformation of TiO2 studied with monodispersed particles. Acta Mater. https://doi.org/10.1016/j.actamat.2004.07.020

Terry BS, Chinyamakobvu O (1991) Carbothermic reduction of ilmenite and rutile as means of production of iron based Ti(O, C) metal matrix composites. Mater Sci Technol. https://doi.org/10.1179/mst.1991.7.9.842

Gupta SK, Rajakumar V, Grieveson P (1989) The influence of weathering on the reduction of llmenite with carbon. Metall Trans B. https://doi.org/10.1007/BF02655932

Gou H-P, Zhang G-H, Kuo-Chih C (2017) Preparation of titanium carbide powder from ilmenite concentrate. Chem Ind Chem Eng Q. https://doi.org/10.2298/ciceq150521007g

Welham NJ, Williams JS (1999) Carbothermic reduction of llmenite (FeTiO3) and rutile (TiO2). Metall Mater Trans B. https://doi.org/10.1007/s11663-999-0113-7

Dewan MAR, Zhang G, Ostrovski O (2010) Carbothermal reduction of a primary ilmenite concentrate in different gas atmospheres. Metall Mater Trans B. https://doi.org/10.1007/s11663-009-9308-1

Zhang H, Banfield JF (2000) Understanding polymorphic phase transformation behavior during growth of nanocrystalline aggregates: Insights from TiO2. J Phys Chem B. https://doi.org/10.1021/jp000499j

Xing X, Du Y, Zheng J et al (2020) Experimental study on strengthening carbothermic reduction of vanadium-titanium-magnetite by adding CaF2. Minerals. https://doi.org/10.3390/min10030219

Nur NF, Najmi NH, Munusamy SRR, Idris MA (2019) Effect of high temperature on reduction-controlling reaction rate of agricultural waste chars and coke with steelmaking slag. J Therm Anal Calorim. https://doi.org/10.1007/s10973-019-08221-9

Sekiya T, Yagisawa T, Kamiya N et al (2004) Defects in anatase TiO2 single crystal controlled by heat treatments. J Phys Soc Japan. https://doi.org/10.1143/JPSJ.73.703

He C, Zheng C, Dai W et al (2021) Purification and phase evolution mechanism of titanium oxycarbide (Ticxoy) produced by the thermal reduction of ilmenite. Minerals. https://doi.org/10.3390/min11020104

Zhang R, Hou Y, Fan G et al (2022) Gas-based reduction and carbonization of titanium minerals in titanium-bearing blast furnace slag: a combined thermodynamic, experimental and DFT study. Int J Hydrogen Energy. https://doi.org/10.1016/j.ijhydene.2021.12.119

T Mojisola, MM Ramakokovhu, PA Olubambi WRM, RM Manamela and AM (2019) Reduction sequence and mechanism of carbothermic reduction of low grade titanium ore: a case study on South African ilmenite. In: The Eleventh International Heavy Mineral Conference—SAIMM. pp. 41–51. http://surl.li/jsffm

Acknowledgements

The authors gratefully acknowledge the financial support from the Fundamental Research Grant Scheme (FRGS) under Grant Number of FRGS/1/2020/TK0/UNIMAP/02/30 from the Ministry of Higher Education and sponsored by UNESCO/Japan Young Researchers’ Fellowship Programme-Cycle 2019. We also thank the Research Management and Innovation Center (RMIC), Faculty of Mechanical Engineering Technology and Faculty of Chemical Engineering Technology, Universiti Malaysia Perlis, (UniMAP) for the facilities provided.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

The contributing editor for this article was Il Sohn.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yunos, N.F.M., Idris, M.A., Nasrun, N.A. et al. Structural Characterizations and Phase Transition on the Reducibility of Ilmenite Ore with Different Carbon Reductants by Carbothermal Reduction Under Hydrogen Atmosphere. J. Sustain. Metall. 9, 1716–1731 (2023). https://doi.org/10.1007/s40831-023-00760-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40831-023-00760-8