Abstract

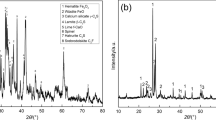

Removal of oxides on the surface of flat steels with hydrochloric acid before galvanising is a common process in steel manufacturing. During this process, a significant amount of iron ions accumulates in the spent acid solution. Recovery of metals and acids from pickling solutions is essential for environmental protection and the economy. Therefore, different techniques are developed for acid and metal recovery from spent pickling solutions. Spray roasting is one of the most widely used techniques for the recovery of HCl from pickling solutions. In this process, while HCl is recovered by evaporation, iron is obtained as iron oxide (FexOy) granules. In this study, the production of iron boride (Fe2B) from high purity iron oxide produced as pickling waste was investigated. Single-phase nanocrystalline Fe2B production by a one-step carbothermic reduction process using waste FexOy and diboron trioxide (B2O3) has been carried out for the first time. The effect of temperature (1273–1473 K) and time (30–270 min) on Fe2B production at constant stoichiometric weight ratios of FexOy/B2O3/C = 3.47/1.56/1.53 was investigated. The produced particles were characterized using X-ray diffraction (XRD), scanning electron microscopy (SEM), and a vibrating sample magnetometer (VSM). XRD results showed that synthesis temperature and duration primarily control Fe2B formation. Fe2B particles with a crystalline size of 39 nm were successfully produced at 1473 K and 270 min. The saturation magnetization, permanent magnetization, and coercivity values of the produced nanocrystalline alloy were determined as 137 emu/g, 22.51 Oe, and 0.812 emu/g, respectively.

Graphical Abstract

Similar content being viewed by others

References

Zheng GH, Kozinski JA (1996) Solid waste remediation in the metallurgical industry: application and environmental impact. Environ Prog 15:283–292. https://doi.org/10.1002/ep.670150419

Iluţiu-Varvara DA, Aciu C (2022) Metallurgical wastes as resources for sustainability of the steel industry. Sustain 14(9):5488–5513. https://doi.org/10.3390/su14095488

Jursová S (2010) Metallurgical waste and possibilities of its processing. Met 2010 - 19th Int Conf Metall Mater Conf Proc, 115–120, Rožnov pod Radhoštěm, Česká Republika

Matinde E, Simate GS, Ndlovu S (2018) Mining and metallurgical wastes: a review of recycling and re-use practices. J South African Inst Min Metall 118:825–844. https://doi.org/10.17159/2411-9717/2018/v118n8a5

Kuklık V, Kudlacek J (2016) Hot-dip galvanizing of steel structures. Elsevier, Amsterdam

Regel-Rosocka M (2010) A review on methods of regeneration of spent pickling solutions from steel processing. J Hazard Mater 177:57–69. https://doi.org/10.1016/j.jhazmat.2009.12.043

Lorenz M, Seitfudem G, Randazzo S et al (2023) Combining membrane and zero brine technologies in waste acid treatment for a circular economy in the hot-dip galvanizing industry: a life cycle perspective. J Sustain Metall. https://doi.org/10.1007/s40831-023-00668-3

Schiemann M, Wirtz S, Scherer V, Bärhold F (2012) Spray roasting of iron chloride FeCl2: laboratory scale experiments and a model for numerical simulation. Powder Technol 228:301–308. https://doi.org/10.1016/j.powtec.2012.05.037

Harris LJF (1994) Introduction to spray roasting process for hydrochloric acid regeneration and its application to mineral processing. Hydrometall 94:923–937. https://doi.org/10.1007/978-94-011-1214-7_62

Regel-Rosocka M, Cieszynska A, Wisniewski M (2007) Methods of regeneration of spent pickling solutions from steel treatment plants. Polish J Chem Technol 9:42–45. https://doi.org/10.2478/v10026-007-0023-x

Gueccia R, Winter D, Randazzo S et al (2021) An integrated approach for the HCl and metals recovery from waste pickling solutions: pilot plant and design operations. Chem Eng Res Des 168:383–396. https://doi.org/10.1016/j.cherd.2021.02.016

Ozdemir I, Ogawa K, Sato K (2014) Iron boron based powders sprayed by high velocity spray processes. Surf Coatings Technol 240:373–379. https://doi.org/10.1016/j.surfcoat.2013.12.056

Oğuz A (2016) Fluidized bed design suitable for reduction with hydrogen and metallic iron production from steel pickling waste. MD Thesis, Istanbul Technical University, Istanbul

Zhao Q, Li W, Liu C et al (2022) Preparation of anode material of lithium–ion battery by spent pickling liquor. J Sustain Metall 9:148–159. https://doi.org/10.1007/s40831-022-00638-1

Abenojar J, Velasco F, Mota JM, Martínez MA (2004) Preparation of Fe/B powders by mechanical alloying. J Solid State Chem 177:382–388. https://doi.org/10.1016/j.jssc.2003.01.001

Wang D, Ma L, Li L et al (2018) Characterization of polycrystalline Fe2B compound with high saturation magnetization. J Supercond Nov Magn 31:431–435. https://doi.org/10.1007/s10948-017-4233-z

Wei Y, Liu Z, Ran S et al (2017) Synthesis and properties of Fe–B powders by molten salt method. J Mater Res 32:883–889. https://doi.org/10.1557/jmr.2017.38

Kartal L, Daryal MB, Timur S (2020) A new approach for Cu and Fe/FexB production from chalcopyrite by molten salt electrolysis. J Sustain Metall 6:751–760. https://doi.org/10.1007/s40831-020-00312-4

Kartal L (2022) Single Fe2B phase particle production by calciothermic reduction in molten salt. Hittite J Sci Eng 9:145–150. https://doi.org/10.17350/HJSE19030000

Sireli GK (2016) Molten salt baths: electrochemical boriding. In: Colás R, Totten GE (eds) Encyclopedia of iron, steel, and their alloys, 1st edn. Taylor and Francis, Wales, pp 2284–2300

Simsek T, Baris M, Kalkan B (2017) Mechanochemical processing and microstructural characterization of pure Fe2B nanocrystals. Adv Powder Technol 28:3056–3062. https://doi.org/10.1016/j.apt.2017.09.017

Mertdinç S, Ağaoğulları D, Öveçoğlu ML (2018) Mechanochemically synthesized Fe2B nanoparticles embedded in SiO2 nanospheres. Ceram Int 44:14834–14843. https://doi.org/10.1016/j.ceramint.2018.05.116

Mohammadi M, Ghasemi A, Tavoosi M (2016) Mechanochemical synthesis of nanocrystalline Fe and Fe–B magnetic alloys. J Magn Magn Mater 419:189–197. https://doi.org/10.1016/j.jmmm.2016.06.037

Yücel O, Cinar F, Addemir O, Tekin A (1996) The preparation of ferroboron and ferrovanadium by Aluminothermic reduction. High Temp Mater Process 15:103–109. https://doi.org/10.1515/HTMP.1996.15.1-2.103

Verma PC, Mishra SK (2019) Synthesis of iron boride powder by carbothermic reduction method. Mater Today Proc 28:902–906. https://doi.org/10.1016/j.matpr.2019.12.321

Barış M, Şimşek T, Taşkaya H (2018) Synthesis of Fe–Fe2B catalysts via solvothermal route for hydrogen generation by hydrolysis of NaBH4. J Boron 3:51–62. https://doi.org/10.30728/boron.348291

Cheng Y, Choi S, Watanabe T (2013) Effect of nucleation temperature and heat transfer on synthesis of Ti and Fe boride nanoparticles in RF thermal plasmas. Powder Technol 246:210–217. https://doi.org/10.1016/j.powtec.2013.05.028

Zakharov G, Aslamazashvili Z, Chikhradze M et al (2021) production of ferroboron from wastes by shs-metallurgy and influence of ligatures on the structure/properties of cast iron. IOP Conf Ser Earth Environ Sci. https://doi.org/10.1088/1755-1315/906/1/012008

Şimşek T, Avar B, Şimşek T et al (2021) A single step synthesis by mechanical alloying and characterization of nanostructured Fe2B of high magnetic moment. Ceram Int 47:26119–26124. https://doi.org/10.1016/j.ceramint.2021.06.018

Ross JRH (2019) Catalyst Characterization. In: Ross JRH (ed) Contemporary catalysis fundamentals and current applications. Elsevier, Amsterdam, pp 121–132

Yucel O, Addemir O, Tekin A (1992) the optimization of parameters for the carbothermic production of ferroboron. Infacon 6(1):285–289

Arslan M, Ok AC, Kartal Sireli G, Timur S (2022) Investigation on structural and tribological properties of borided gear steel after phase homogenization. Surf Coatings Technol 429:1–14. https://doi.org/10.1016/j.surfcoat.2021.127967

Kartal G, Eryilmaz OL, Krumdick G et al (2011) Kinetics of electrochemical boriding of low carbon steel. Appl Surf Sci 257:6928–6934. https://doi.org/10.1016/j.apsusc.2011.03.034

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author declares no conflict of interest.

Additional information

The contributing editor for this article was Yongxiang Yang.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kartal, L. Singe Phase Iron Boride (Fe2B) Particle Production from Pickling Wastes by One Step Carbothermic Reduction. J. Sustain. Metall. 9, 1660–1669 (2023). https://doi.org/10.1007/s40831-023-00755-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40831-023-00755-5