Abstract

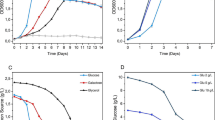

Due to the existence of large auxiliary material consumption, huge wastewater discharge, and high production cost in present tungsten extractive metallurgy practice, a novel technology featuring sulfuric acid conversion-ammonium salts leaching was proposed. Based on the complete conversion of tungsten minerals in sulfuric acid solution, this paper studied the leaching of WO3 from sulfuric acid converted product of scheelite in NH3·H2O–(NH4)2C2O4 solution. The effect of leaching conditions on WO3 leaching efficiency and solid phase transformation was systemically investigated. The WO3 leaching efficiency was > 98% under optimized conditions of 1 mol/L (NH4)2C2O4, 3 mol/L NH3·H2O, 350 rpm, 5 min, and 25 °C. The formed flaky CaC2O4·H2O densely covered on the surface of banding or rodlike shaped CaSO4, which prevented the further transformation of CaSO4. The morphology of leaching residue was more irregular for converted product of scheelite concentrate than that for synthetic scheelite. Minor secondary reaction between CaSO4 and (NH4)2WO4 might occur with increased (NH4)2WO4 concentration, which could be restrained by the existence of (NH4)2C2O4 in solution due to the larger Ksp value of CaC2O4·H2O than CaWO4. The leaching process could be explained by acid–base neutralization of H2WO4 and phase transformation of CaSO4 in NH3·H2O–(NH4)2C2O4 solution.

Graphical Abstract

Similar content being viewed by others

References

Lassner E, Schubert WD, Lüderitz E et al (2012) Tungsten, tungsten alloys, and tungsten compounds. In: Ullmann’s encyclopedia of industrial chemistry, vol 37. Wiley-VCH Verlag Gmb H & Co. KGa A, Weinheim, pp 498–536

Shen L, Li X, Lindberg D, Taskinen P (2019) Tungsten extractive metallurgy: a review of processes and their challenges for sustainability. Miner Eng 142:105934

Gunn G (2014) Critical metals handbook, chapter 16, tungsten. British Geological Survey/American Geophysical Union/Wiley, Keyworth, Nottingham, UK, pp 385–413

Liu LX (2012) China’s tungsten resources and mining status. China Tungsten Ind 27:4–8

BGS (2012) Risk list 2012. British Geological Survey, Keyworth

Choi W, Park C, Song Y et al (2020) Sequential scheelite mineralization of quartz-scheelite veins at the Sangdong W-deposit: microtextural and geochemical approach. Minerals 10:1–25

Malyshev VV, Kushchevska NF (2019) Production of tungsten and tungsten carbide powders. Powder Metall Met Ceram 58:237–242

Polini R, Marcucci A, D’Ottavi C et al (2021) Toward greener synthesis of WC powders for cemented tungsten carbides manufacturing. ACS Sustain Chem Eng 9:8458–8466

Barth VD, Mcintire HO (1965) Tungsten powder metallurgy. NASA Press, Washington, DC

Li HG, Liu MS, Sun PM et al (1995) Caustic decomposition of scheelite and scheelite-wolframite concentrates through mechanical activation. J Cent South Univ Technol 2:16–20

Zhao ZW, Liang Y, Liu XH et al (2011) Sodium hydroxide digestion of scheelite by reactive extrusion. Int J Refract Met Hard Mater 29:739–742

Ren HC, Li JT, Tang ZY et al (2020) Sustainable and efficient extracting of tin and tungsten from wolframite–scheelite mixed ore with high tin content. J Clean Prod 269:122282

Chen YL, Huo GS, Guo XY et al (2022) Sustainable extraction of tungsten from the acid digestion product of tungsten concentrate by leaching-solvent extraction together with raffinate recycling. J Clean Prod 375:133924

Kim TK, Towanda PA (1979) Process for extracting tungsten from alkali metal tungstate solutions. US Patent 4175109

Kholmogorov AG, Kononova ON, Kachin SV (1999) Ion exchange hydrometallurgy of tungsten using anion exchangers with long-chained cross-linking agents. Hydrometallurgy 53:177–187

Zhao ZW, Li JT, Wang SB et al (2011) Extracting tungsten from scheelite concentrate with caustic soda by autoclaving process. Hydrometallurgy 108:152–156

Yang L, Zhang XY, Cao CF et al (2022) A new process for the efficient decomposition of low-grade scheelite based on the formation of insoluble calcium fluorophosphate. Miner Eng 177:107372

Gong DD, Zhang Y, Wan LS et al (2022) Efficient extraction of tungsten from scheelite with phosphate and fluoride. Process Saf Environ Prot 159:708–715

Davey TR (1990) Method of extracting tungsten values from tungsten containing ores. US Patent 4910000

Martins JI (2003) Leaching of synthetic scheelite by nitric acid without the formation of tungstic acid. Ind Eng Chem Res 42:5031–5036

Martins JI, Moreira A, Costa SC (2003) Leaching of synthetic scheelite by hydrochloric acid without the formation of tungstic acid. Hydrometallurgy 70:131–141

Chen Y, Huo G, Guo X et al (2023) Leaching behavior and mechanism of scheelite and wolframite in treating a mixed scheelite-wolframite concentrate by hydrochloric acid. J Sustain Metall. https://doi.org/10.1007/s40831-023-00696-z

Kalpakli AO, Ilhan S, Kahruman C et al (2012) Dissolution behavior of calcium tungstate in oxalic acid solutions. Hydrometallurgy 121:7–15

Potashnikov YM, Gamol’skii AM, Mokhosoev MV et al (1970) Kinetics of the dissolution of calcium tungstate in oxalate acid solution. Zh Neorg Khim 15:502–508

Liu QS, Tu T, Guo H, Cheng HJ, Wang XZ (2021) Complexation extraction of scheelite and transformation behavior of tungsten-containing phase using H2SO4 solution with H2C2O4 as complexing agent. Trans Nonferrous Met Soc China 31:3150–3161

Li J, Zhao Z (2016) Kinetics of scheelite concentrate digestion with sulfuric acid in the presence of phosphoric acid. Hydrometallurgy 163:55–60

Zhang WJ (2016) Study on new technology of efficient utilization of low grade complex tungsten ore. Central South University, Hunan

Zhao ZW, Li JT (2014) Method for extracting tungsten from scheelite. US Patent 8771617

Zhao ZW, Chen XY, Liu XH et al (2017) The challenge and development for the tungsten extraction technique under the new situation. Conserv Util Miner Resour 1:98–102

Liu X, Zhai J, Chen X et al (2022) Recovery of tungsten in the process of preparation of calcium sulfate whiskers from scheelite decomposed residue. ACS Sustain Chem Eng 10:13194–13204

Yin CS, Ji L, Chen XY et al (2020) Efficient leaching of scheelite in sulfuric acid and hydrogen peroxide solution. Hydrometallurgy 192:105292

Zhang WJ, Chen YQ, Che JY et al (2022) Green leaching of tungsten from synthetic scheelite with sulfuric acid hydrogen peroxide solution to prepare tungstic acid. Sep Purif Technol 241:116752

Li XB, Shen LT, Zhou QS et al (2017) Scheelite conversion in sulfuric acid together with tungsten extraction by ammonium carbonate solution. Hydrometallurgy 171:106–115

Shen LT, Li XB, Zhou QS et al (2018) Wolframite conversion in treating a mixed wolframite–scheelite concentrate by sulfuric acid. JOM 70:161–167

Shen LT, Li XB, Zhou QS et al (2018) Kinetics of scheelite conversion in sulfuric acid. JOM 70:2499–2504

Shen LT, Li XB, Zhou QS et al (2018) Sustainable and efficient leaching of tungsten in ammoniacal ammonium carbonate solution from the sulfuric acid converted product of scheelite. J Clean Prod 197:690–698

Speight JG (2005) Lange’s handbook of chemistry, 16th edn. McGraw-Hill, New York

Van Put JW, De Koning PM (1992) Kinetics of and an adsorption model for the dissolution of synthetic WO3 in aqueous ammonia. Hydrometallurgy 28:353–366

Van Put JW, Van Den Berg J (1988/1989) Crystallization of ammonium paratungstate. Delft Prog Rep 13:39–48

Acknowledgements

This work is financially supported by the Grant of National Natural Science Foundation of China (No. 52304374) and Starting-up Funding in Central South University (No. 220208).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing Interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

The contributing editor for this article was Nikhil Dhawan.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, L., Shen, L., Zhou, Q. et al. Leaching of WO3 from Sulfuric Acid Converted Product of Scheelite in NH3·H2O–(NH4)2C2O4 Solution. J. Sustain. Metall. 9, 1589–1600 (2023). https://doi.org/10.1007/s40831-023-00750-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40831-023-00750-w