Abstract

Ti6Al4V alloy is a widely used titanium alloy. During the vacuum smelting of Ti6Al4V alloys, the Al is highly volatile, which leads to the difficulties in the control of alloy composition. Thus, studying the compositional volatile mechanism of the alloy is of significance. In this work, the infinite dilution coefficients of Ti6Al4V are calculated by the α-function method. The activity coefficient is predicted by the molecular interaction volume model. The Langmuir formula is modified to predict the alloying of Ti6Al4V. When the average temperature of the bath is 2050 K, the content of V in Ti6Al4V is 4%, and the proportion of Al in the alloy is \({\text{y}} \, = \text{ } \, \text{0.0067}{\text{x}}^{3}\text{+0.129}{\text{x}}^{2}\text{+0.1627x+2.763}\), where \(x\) is the percentage of Al required in the alloy. The experimental results show that the predicted value is in good agreement with the experimental value.

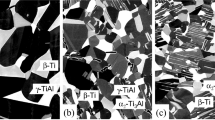

Graphical Abstract

Similar content being viewed by others

References

Liu Y, Zhou-De QU, Wang BX (2005) Research development and application of Ti6A14V alloy. Ordnance Mater Sci Eng 28:47–40

Froes FH, Friedrich H, Kiese J, Bergoint D (2004) Titanium in the family automobile: the cost challenge. JOM 56:40–44. https://doi.org/10.1007/s11837-004-0144-0

Harker HR (1990) Experience with large scale electron beam cold hearth melting (EBCHM). Vacuum 41:2154–2156. https://doi.org/10.1016/0042-207X(90)94211-8

Wood JR (2002) Producing Ti-6Al-4V plate from single-melt EBCHM ingot. JOM 54:56–58. https://doi.org/10.1007/BF02701077

Bomberger HB, Froes FH (1984) The melting of titanium. JOM 36:39–47. https://doi.org/10.1007/BF03339212

Xie Y, Jinhui XI, Henglei QU, Deng C (2010) Comparison of VAR controlling styles during remelting large-sized TC4 ingots. Hot Working Technol 39:60–62

Yang HW, Zhang C, Yang B et al (2015) Vapor–liquid phase diagrams of Pb–Sn and Pb–Ag alloys in vacuum distillation. Vacuum 119:179–184. https://doi.org/10.1016/J.VACUUM.2015.05.017

Yuehou Y, Changzai Z (2015) Modification of langmuir formular on vacuum evaporation rate of metal and measured results of Dy, Tb and Al. Chinese J Vacuum Sci Technol 35:386–390

Yongwei Zhang (2018) Study of volatilization mechanism and dosing parameters of TC4 group elements. MD Thesis, Kunming University of science and Technology

Jiang G, Liu Y, Li Y et al (2007) Improvement of calculation method for the activity coefficient of multi-component alloys. Acta Metall Sin 43:503–508

Wang S, Xu B, Li Y et al (2022) The investigation of removal and occurrence state of impurity elements during crude tin vacuum distillation. J Sustain Metall 8:700–714. https://doi.org/10.1007/S40831-022-00506-Y/TABLES/10

Wang S, Tao DP, Yang HW (2008) Verification of thermodynamic consistency of component activity data of binary liquid alloys. J Kunming Univ Sci Technol (Science and Technology) 33:15–19

Wei S (1964) Application of activity in metallurgical physical chemistry. China Industrial Press, Beijing

Odusote YA, Jabar JM, Bolarinwa HS, Akinbisehin AB (2019) Application of molecular interaction volume model in separation of Ti-Al alloys in vacuum distillation. Vacuum 169:108885. https://doi.org/10.1016/j.vacuum.2019.108885

Zhu Y, Yang YQ, Ma ZJ, Chen Y (2002) Calculation of activity cofficients for components in ternary alloys and intermetallics. J Northwest Inst Textile Sci Technol 16(2):124–128

Gokcen NA (1986) Statistical thermodynamics of alloys. Statistical thermodynamics of alloys. Springer, Boston

You X, Shi S, Tan Y et al (2019) The evaporation behavior of alloy elements during electron beam smelting of Inconel 718 alloy. Vacuum 169:108920. https://doi.org/10.1016/J.VACUUM.2019.108920

Xueyong D, Peng F, Qiyong H (1994) Models of activity and activity interaction parameter in ternary metallic melt. Acta Metall Sin 30:49–60

Wang D, Dai Y (1996) The correlations of activity coefficients to Miedema’s heat of formation in multicomponent liquid alloys. J Kunming Univ Sci Technol 21:75–79

Wang S (2008) Verification of thermodynamic consistency of component activity data of binary liquid alloys. MD Thesis, Kunming University of science and Technology

Kim H, Boysen DA, Bradwell DJ et al (2012) Thermodynamic properties of calcium-bismuth alloys determined by emf measurements. Electrochim Acta 60:154–162. https://doi.org/10.1016/j.electacta.2011.11.023

Poizeau S, Sadoway DR (2013) Application of the molecular interaction volume model (MIVM) to calcium-based liquid alloys of systems forming high-melting intermetallics. J Am Chem Soc 135:8260–8265. https://doi.org/10.1021/ja4013886

Dai H, Tao DP (2019) Application of the modified molecular interaction volume model (M-MIVM) to vapor-liquid phase equilibrium of binary alloys in vacuum distillation. Vacuum 163:342–351. https://doi.org/10.1016/J.VACUUM.2019.02.041

Song B et al (2016) Study on azeotropic point of Pb–Sb alloys by ab-initio molecular dynamic simulation and vacuum distillation. Vacuum 125:209–214

Zhao W, Xu B, Yang B, Yang H (2021) Study on evaporation kinetics of Zn in Bi–Zn and Bi–Sn–Zn systems under vacuum condition. J Sustain Metall 7:995–1003. https://doi.org/10.1007/S40831-021-00386-8/FIGURES/9

Dai Y, Yang B (2000) Vacuum metallurgy of nonferrous metal materials. Metallurgical Industry press, Beijing

Maeda M, Kiwake T, Shibuya K, Ikeda T (1997) Activity of aluminum in molten Ti–Al alloys. Mater Sci Eng, A 240:276–280. https://doi.org/10.1016/S0921-5093(97)00593-5

Shuai X, Song B, Jiang W, Yang B (2015) Modeling and calculation of activities of constituent elements in binary alloys. Chinese J Vacuum Sci Technol 35:919–925. https://doi.org/10.13922/j.cnki.cjovst.2015.08.02

Hultgren H, Desai P, Hawkins D et al (1973) Selected values of the thermodynamic properties of binary alloys. ASM, Metals Park, OH

Acknowledgements

This work has been funded by the National Natural Science Foundation of China (51874156, 52064029, 21968013, 51674129).

Author information

Authors and Affiliations

Corresponding author

Additional information

The contributing editor for this article was M. Akbar Rhamdhani.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Deng, J., Zhang, Y., Jiang, W. et al. Volatilization Mechanism of Group Elements in Ti6Al4V During Electron Beam Cold Hearth Melting. J. Sustain. Metall. 9, 1477–1486 (2023). https://doi.org/10.1007/s40831-023-00740-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40831-023-00740-y