Abstract

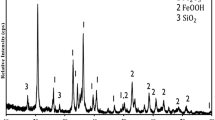

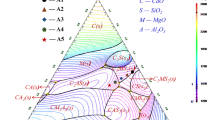

In this study, binary f-CaO in steel slag was simulated and prepared. By synthesizing different proportions of binary f-CaO, the influence of carbonization on the binary f-CaO, its carbonization performance, and hydration activity were investigated. When the iron content increased, the hydration activity of binary f-CaO decreased, and the hydration rate of the CaO·0.3FeO sample (77.01%) was the lowest. The main products of binary f-CaO carbonization are cubic calcite and rod-shaped aragonite. With the progress of carbonization, the carbonization degree of binary f-CaO increased and then decreased with the increase in iron content. Among them, the carbonization rate of CaO·0.1FeO was the highest (96.91%). The carbonization can effectively react Ca2Fe2O5 in binary f-CaO to improve its carbonization degree. Finally, compared with hydration, the ability of carbonization to remove CaO was improved by 18.01%.

Graphical Abstract

Similar content being viewed by others

References

Han F, Zhang Z, Wang D (2015) Hydration heat evolution and kinetics of blended cement containing steel slag at different temperatures. Thermochim Acta 605:43–51

Shi C (2004) Steel slag—its production, processing, characteristics, and cementitious properties. J Mater Civ Eng 16:230–236

World Steel Association (2022) World steel in figures 2022 now available. Brussels, Belgium. https://worldsteel.org/media-centre/press-releases/2022/world-steel-in-figures-2022-now-available/

Zhao J, Yan P, Wang D (2017) Research on mineral characteristics of converter steel slag and its comprehensive utilization of internal and external recycle. J Clean Prod 156:50–61

Zhou X, Xiang X, Li C (2014) Ecological security analysis and advances in innocent treatment of steel slag. Multipurp Util Miner Res 3:8–11

Song Q, Guo M, Wang L, Ling T (2021) Use of steel slag as sustainable construction materials: a review of accelerated carbonation treatment. Resour Conserv Recycl 173:105740

Luo Y, He D (2021) Research status and future challenge for CO2 sequestration by mineral carbonation strategy using iron and steel slag. Environ Sci Pollut Res 28:49383–49409

Bonenfant D, Kharoune L, Sauve S (2008) CO2 sequestration potential of steel slags at ambient pressure and temperature. Ind Eng Chem Res 47:7610–7616

Guo J, Bao Y, Min W (2018) Steel slag in China: treatment, recycling, and management. Waste Manage 78:318–330

Gao T, Dai T, Shen L (2021) Benefits of using steel slag in cement clinker production for environmental conservation and economic revenue generation. J Clean Prod 282:124538

López MM, Pineda Y, Gutiérrez O (2015) Evaluation of durability and mechanical properties of the cement mortar added with slag blast furnace. Procedia Mater Sci 9:367–376

Xiang XD, Xi JC, Li CH (2016) Preparation and application of the cement-free steel slag cementitious material. Constr Build Mater 114:874–879

Wang Y, Suraneni P (2019) Experimental methods to determine the feasibility of steel slags as supplementary cementitious materials. Constr Build Mater 204:458–467

Mo L, Yang S, Huang B (2020) Preparation, microstructure and property of carbonated artificial steel slag aggregate used in concrete. Cement Concr Compos 113:103715

Ghouleh Z, Guthrie RIL, Shao Y (2017) Production of carbonate aggregates using steel slag and carbon dioxide for carbon-negative concrete. J CO2 Util 18:125–138

Dong Q, Wang G, Chen X (2020) Recycling of steel slag aggregate in portland cement concrete: an overview. J Clean Prod 282:124447

Jiang Y, Ling TC, Shi C, Pan SY (2018) Characteristics of steel slags and their use in cement and concrete—a review. Res Conserv Recycl 136:187–197

Wang G, Wang Y, Gao Z (2010) Use of steel slag as a granular material: Volume expansion prediction and usability criteria. J Hazard Mater 184:555–560

George W (2010) Determination of the expansion force of coarse steel slag aggregate—sciencedirect. Constr Build Mater 24:1961–1966

Waligora J, Bulteel D, Degrugilliers P (2010) Chemical and mineralogical characterizations of LD converter steel slags: a multi-analytical techniques approach. Mater Charact 61:39–48

Shen DH, Wu CM, Du JC (2009) Laboratory investigation of basic oxygen furnace slag for substitution of aggregate in porous asphalt mixture. Constr Build Mater 23:453–461

Yildirim IZ, Prezzi M (2011) Chemical, mineralogical, and morphological properties of steel slag. Adv Civil Eng 2011:88–100

Shen H, Forssberg E, Nordstrm U (2004) Physicochemical and mineralogical properties of stainless steel slags oriented to metal recovery—sciencedirect. Resour Conserv Recycl 40:245–271

Setién J, Hernández D, González JJ (2009) Characterization of ladle furnace basic slag for use as a construction material. Constr Build Mater 23:1788–1794

Mo L, Feng Z, Min D (2017) Accelerated carbonation and performance of concrete made with steel slag as binding materials and aggregates. Cement Concr Compos 83:138–145

Salman M, Cizer Pontikes Y (2015) Cementitious binders from activated stainless steel refining slag and the effect of alkali solutions. J Hazard Mater 286:211–219

Kriskova L, Pontikes Y, Cizer Ö (2012) Effect of mechanical activation on the hydraulic properties of stainless steel slags. Cem Concr Res 42:778–788

Wu Z-H, Zou Z-S, Wang C-Z (2005) Application of converter slags in agriculture. Multipurp Util Miner Res 6:25–28

Jia R, Liu J (2017) A study of factors that influence the hydration activity of mono-component CaO and bi-component CaO/Ca2Fe2O5 systems. Cem Concr Res 91:123–132

Shi H, Zhao Y, Li W (2002) Effects of temperature on the hydration characteristics of free lime. Cem Concr Res 32:789–793

Lu TH, Chen YL, Shih PH (2018) Use of basic oxygen furnace slag fines in the production of cementitious mortars and the effects on mortar expansion. Constr Build Mater 167:768–774

Wang Q, Wang D, Zhuang S (2017) The soundness of steel slag with different free CaO and MgO contents. Constr Build Mater 151:138–146

Jia R, Liu J (2016) Simulated experiment study of factors influencing the hydration activity of f-CaO in basic oxygen furnace slag. Adv Mater Sci Eng 2016:15

Ji X, Hou J, Liu Y (2019) Effect of CaO-FeO-MnO system solid solution on the hydration activity of tri-component f-CaO in steel slag. Constr Build Mater 225:476–484

Hou XK, Xu DL, Xue B (2012) Study on volume stability problems of cement caused by steel slag. J Build Mater 15:588–595

Mingshu T, Meixi Y, Sufen H, Xing S (1979) The crystalline state of MgO, FeO and MnO in steel slag and the soundness of steel slag cement (in Chinese). J Chin Ceram Soc 7:35–46

Liu P, Mo L, Zhang Z (2023) Effects of carbonation degree on the hydration reactivity of steel slag in cement-based materials. Constr Build Mater 370:130653

Mohamed A-M, El-Gamal M, Hameedi S (2022) Sustainable utilization of carbon dioxide in waste management. Elsevier, pp 327–372

Chen Z, Li R, Zheng X (2021) Carbon sequestration of steel slag and carbonation for activating RO phase. Cem Concr Res 139:106271

Yang T, Gao X, Zhang Q et al (2023) Accelerated carbonation of one-part sodium carbonate-activated slag cements modified by calcined dolomite. Constr Build Mater 375:131013

Ma Z, Liao H, Wang L, Cheng F (2021) Effects of iron/silicon/magnesium/aluminum on CaO carbonation of CO2 in steel slag-based building materials during carbonation curing. Constr Build Mater 298:123889

Funding

This work was supported by the National Natural Science Foundation of China (Grant No. 52074019, 51874013).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

The contributing editor for this article was Sharif Jahanshahi.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, Z., Chen, T. & Liu, J. Study on Carbonization Activated Binary f-CaO Phase in Steel Slag. J. Sustain. Metall. 9, 1050–1060 (2023). https://doi.org/10.1007/s40831-023-00710-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40831-023-00710-4