Abstract

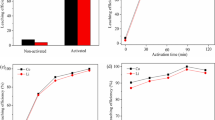

The increasing demand for cobalt within the last two decades supports the reservation and recycling of cobalt bearing spent catalyst. This paper deals with the generation of high pure Co(II) solution as a precursor liquor for the synthesis of either battery grade material or fine chemicals of cobalt. The extraction of cobalt from Co bearing spent catalyst containing about 22.3% of Co with Fe, Mn, Ni and Cu in trace amount was carried out by leaching with nitric acid. The recovery of cobalt was 99.78% at 4 h, whereas recovery of iron was 72.78% with 12.5% acid concentration at 90 °C. The first step was Fe separation through hydrothermal route giving a valuable by product as Fe2O3. To generate a high pure solution; the minor impurities like Cu(II) and Ni(II) and Mn(II) should be removed. Since Co(II), Cu(II) and Ni(II) have similar responses to the precipitating reagents the cobalt (II) needs to get converted to a different form such as Co(III) so that it can be selectively taken out leaving other elements. The Co(III) oxide is dissolved through reductive acid leaching to get Co(II) precursor solution back. The leaching efficiency of cobalt (III) obtained was 99.9% with sample to charcoal ratio (w/w) of 10:3, 2 M HNO3 at 90 °C.The Fe residue and Co(III) oxide is characterized by XRD, SEM to study the phases and structures.

Graphical Abstract

Similar content being viewed by others

Data Availability

All data generated or analyzed during this study are included in this published article and its supplementary information files.

References

Mambazhasseri AD, Minakshi M, Bahri PA, Paul S, Kumari P, Mambazhasseri AD, Manjunatha KN (2021) Rational design on materials for developing next generation lithium-ion secondary battery. Prog Solid State Chem 62:100298

Schuman SC, Shalit H (1971) Hydrodesulfurization. Catalysis Reviews 4(2):245–318

Zuzanna W, Martyna R, Ryszard C, Katarzyna S, Magdalena R (2020) Hydrometallurgical recovery of cobalt(II) from spent industrial catalysts. Catalysts 10(1):61

Uliusman Y., Ramadhan I T. and Huda M (2018) Recovery of Cobalt from leach solution of spent oil Hydrodesulphurization catalyst using a synergistic system consisting of VersaticTM 10 and Cyanex®272rd, IOP Conf. Series: Materials Science and Engineering, 334: 012049

Barik SP, Park K-H, Parhi PK, Park JT (2012) Direct leaching of molybdenum and cobalt from spent hydrodesulphurization catalyst with sulphuric acid. Hydrometallurgy 111–112:46–51

Padhan E, Sarangi K (2014) Separation of molybdenum and cobalt from spent catalyst using Cyanex 272 and Cyanex 301. Int J Miner Process 127:52–61

Park KH, Mohapatra D, WooNam C (2007) Two stage leaching of activated spent HDS catalyst and solvent extraction of aluminium using organo-phosphinic extractant, Cyanex 272. J Hazard Mater 148:287–295

Matjie RH, Scurrell MS, Bunta J (2005) The selective dissolution of alumina, cobalt and platinum from a calcined spent catalyst using different lixiviants. Miner Eng 18:801–810

Rane MV, Bafna VH, Sadanandam R, Sharma AK, Ramadevi K, Menon NK, Fonseca MF, Tangri SK, Suri AK (2005) Recovery of high purity cobalt from spent ammonia cracker catalyst. Hydrometallurgy 77:247–251

Banda R, Nguyen TH, Seong SH, Lee MS (2013) Recovery of valuable metals and regeneration of acid from the leaching solution of spent HDS catalyst by solvent xtraction. Hydrometallurgy 133:161–167

Marafi M, Stanislaus A (2011) Waste catalyst utilization: extraction of valuable metals from spent hydroprocessing catalysts by ultrasonic-assisted leaching with acids. Ind Eng Chem Res 50(16):9495–9501

Valverde Jr IM, Paulino JF, Afonso JC (2008) Hydrometallurgical route to recover molybdenum, nickel, cobalt and aluminum from spent hydrotreating catalysts in sulphuric acid medium. J Hazard Mater 160:310–317

Pathak A, Srichandana H, Dong JK (2019) Column bioleaching of metals from refinery spent catalyst by acidithiobacillus thiooxidans: effect of operational modifications on metal extraction, metal precipitation, and bacterial attachment. J Environ Manage 242:372–383

Srichandana H, Mohapatra RK, Parhi PK, Mishra S (2019) Bioleaching approach for extraction of metal values from secondary solid wastes: a critical review. Hydroemtallurgy 189:105122

Samal RR, Dash B, Sarangi CK, Sanjay K, Subbaiah T, Senanayake G, Minakshi M (2017) Influence of synthesis temperature on the growth and surface morphology of Co3O4 nanocubes for supercapacitor applications. Nanomaterials 7(356):1–13

Samal RR, Samantara AK, Mahalik S, Behera JN, Dash B, Sanjay K (2021) An anionic and cationic surfactant-assisted hydrothermal synthesis of cobalt oxide nanoparticles as the active electrode material for supercapacitors. New J Chem 45:2795–2801

Morales JAM (2017) Synthesis of hematite α-Fe2O3 nano powders by the controlled precipitation method. Ciencia En Desarrollo 8(1):99–107

Lister MW (1956) Decomposition of sodium hypochlorite: the catalyzed reaction. Can J Chem 34:479–488

Mwenesongole, E (2008) A Raman- and XRD study of the crystal chemistry of cobalt blue, Thesis, Master of Science, University of Pretoria

Ren L, Wang P, Han Y, Hu C, Wei B (2009) Synthesis of CoC2O4·2H2O nanorods and their thermal decomposition to Co3O4 nanoparticles. Chem Phys Lett 476:78–83

Ai L, Jiang H (2009) Rapid synthesis of nanocrystalline Co3O4 by a microwave-assisted combustion method. J Powder Technol 195:11–14

Salavati-Niasari M, Mir N, Davar F (2009) Synthesis and characterization of Co3O4 nanorods by thermal decomposition of cobalt oxalate. J Phys Chem Solids 70:847–852

Minakshi M, Sharma N, Ralph D, Appadoo D, Nallatham K (2011) Synthesis and characterization of Li(Co05Ni05)PO4 cathode for Li-Ion aqueous battery applications. Electrochem Solid-State Lett 14(6):A86

Minakshi M, Appadoo D (2020) Traditional salt-in-water electrolyte vs. water-in-salt electrolyte with binary metal oxide for symmetric supercapacitors: capacitive vs. faradaic. Dalton Trans 49:11743–11755

Acknowledgements

The authors are thankful to Director, CSIR-IMMT for providing all facilities to carry out the work and the constant inspiration and guidance. The authors are also thankful to MoES for facility creation which helped in characterizing the samples.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

The contributing editor for this article was Atsushi Shibayama.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Samal, R., Mahalik, S., Routroy, S. et al. High Pure Co (II) Precursor Liquor From Spent Catalyst Leach Liquor. J. Sustain. Metall. 9, 972–981 (2023). https://doi.org/10.1007/s40831-023-00693-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40831-023-00693-2