Abstract

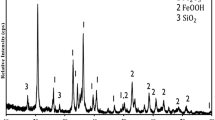

An innovative technique that provides a new way to use vanadium slag and red mud has been developed. In the proposed method, vanadium slag was used to prepare Fe–V alloys by combining the slag with iron-rich red mud. The effects of the red mud dosage, reduction temperature, and Na2CO3 addition on the carbothermal reduction of vanadium slag and iron-rich red mud were investigated. Thermodynamic analysis indicated that optimizing the reduction temperature increased the metal recovery. The roasted samples were tested with X-ray diffraction, scanning electron microscopy, and energy-dispersive X-ray spectroscopy, and the analytical results indicated that a vanadium slag:red mud mass ratio of 40:60 promoted liquid-phase formation and Fe–V alloy grain growth. V and Cr promoted the pearlite transformation and fined the lamellar spacing, imparting higher hardness and improving the electrochemical corrosion resistance of the alloy. Sodium salt addition enhanced the metal recovery by the promoting formation of aluminosilicate slag. This method enables efficient direct reduction of vanadium slag and the production of alloy materials with high added value.

Graphical Abstract

Similar content being viewed by others

References

Diao J, Liu L, Lei J, Tan WF, Li HY, Xie B (2021) Oxidation mechanism of vanadium slag with high MgO content at high temperature. Metall Mater Trans B 52:494–501

Fang HX, Li HY, Zhang T, Liu BS, Xie B (2015) Influence of CaO on existence form of vanadium-containing phase in vanadium slag. ISIJ Int 55:200–206

Semykina A, Dzhebian I, Shatokha V (2012) On the formation of vanadium ferrites in CaO–SiO2–FeO–V2O5 slags. Steel Res Int 83:1129–1134

Li KQ, Jiang Q, Gao L, Chen J, Peng JH, Koppala S, Omran M (2020) Investigations on the microwave absorption properties and thermal behavior of vanadium slag: improvement in microwave oxidation roasting for recycling vanadium and chromium. J Hazard Mater 395:122698

He A, Zeng J (2017) Direct preparation of low Ni–Cr alloy cast iron from red mud and laterite nickel ore. Mater Des 115:433–440

Zhu DQ, Chun TJ, Pan J, He Z (2012) Recovery of iron from high-iron red mud by reduction roasting with adding sodium salt. J Iron Steel Res Int 19:1–5

Guo YH, Gao JJ, Xu HJ, Zhao K, Shi XF (2013) Nuggets production by direct reduction of high iron red mud. J Iron Steel Res Int 20:24–27

Alam S, Das SK, Rao BH (2019) Strength and durability characteristic of alkali activated GGBS stabilized red mud as geo-material. Constr Build Mater 211:932–942

Chowdhury AR, Jaksik J, Hussain I, Longoria R, Faruque O, Cesano F, Scarano D, Parsons J, Uddin MJ (2019) Multicomponent nanostructured materials and interfaces for efficient piezoelectricity. Nano-Struct Nano-Objects 17:148–184

Wang S, Guo YF, Zheng FQ, Chen F, Yang LZ, Jiang T, Qiu GZ (2020) Behavior of vanadium during reduction and smelting of vanadium titanomagnetite metallized pellets. Trans Nonferrous Met Soc China 30:1687–1696

Ustinovshikov Y, Pushkarev B, Sapegina I (2005) Phase transformations in alloys of the Fe–V system. J Alloy Compd 398:133–138

Park J, Shim JH, Lee YK (2016) Room-temperature solid solution softening in Fe–V binary system. Met Mater Int 22:1–7

Wang ZH, Hui WJ, Chen Z, Zhang YJ, Zhao XL (2020) Effect of vanadium on microstructure and mechanical properties of bainitic forging steel. Mater Sci Eng A 771:138653

Liu W, Yang J, Xiao B (2009) Application of Bayer red mud for iron recovery and building material production from alumosilicate residues. J Hazard Mater 161:474–478

Li XB, Xiao W, Liu W, Liu GH, Peng ZH, Zhou QS, Qi TG (2009) Recovery of alumina and ferric oxide from Bayer red mud rich in iron by reduction sintering. Trans Nonferrous Met Soc China 19:1342–1347

Li ZF, Zhang J, Li SC, Lin CJ, Gao YF, Liu C (2020) Feasibility of preparing red mud-based cementitious materials: synergistic utilization of industrial solid waste, waste heat, and tail gas. J Clean Prod 285:124896

Wang XP, Sun TC, Kou J, Li ZC, Tian Y (2018) Feasibility of co-reduction roasting of a saprolitic laterite ore and waste red mud. Int J Miner Metall Mater 25:591–597

Li GH, Jun L, Peng ZW, Zhang YB, Rao MJ, Jiang T (2015) Effect of quaternary basicity on melting behavior and ferronickel particles growth of saprolitic laterite ores in Krupp-Renn process. ISIJ Int 55:1828–1833

Cao HT, Dong XP, Chen SQ, Dutka M, Pei YT (2017) Microstructure evolutions of graded high-vanadium tool steel composite coating in-situ fabricated via atmospheric plasma beam alloying. J Alloys Compd 720:169–181

Grudinsky P, Zinoveev D, Yurtaeva A, Kondratiev A, Dyubanov V, Petelin A (2021) Iron recovery from red mud using carbothermic roasting with addition of alkaline salts. J Sustain Metall 7:858–873

Li Y (2010) The effects of V on phase transformation of high carbon steel during continuous cooling. Acta Metall Sin 46:1501–1510

Niu G, Chen YL, Wu HB, Wang X, Zuo MF, Xu ZJ (2016) Effects of chromium, vanadium and austenite deformation on transformation behaviors of high-strength spring steels. J Iron Steel Res Int 23:1323–1332

Sourmail T, Garcia-Mateo C, Caballero FG, Cazottes S, Epicier T, Danoix F, Milbourn D (2017) The influence of vanadium on ferrite and bainite formation in a medium carbon steel. Mater Sci Eng A 48:3985–3996

Todić A, Čikara D, Pejović B, Todić T, Čamagić I, Mićić V, Yusup S (2017) The influence of the vanadium content on the toughness and hardness of wear resistant high-alloyed Cr–Mo steel. FME Trans 45:130–134

Li YJ, Dong SY, Yan SX, Liu XT, He P, Xu BS (2018) Microstructure evolution during laser cladding Fe–Cr alloy coatings on ductile cast iron. Opt Laser Technol 108:255–264

Acknowledgements

This work was financially supported by Natural Science Foundation of Henan province [Grant Number 222300420437].

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

The contributing editor for this article was Adam Clayton Powell.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, W., Wang, W. & Sun, Q. Utilization of Vanadium Slag and Iron-Rich Red Mud for the Fabrication of Fe–V Alloy: Mechanism and Performance Analysis. J. Sustain. Metall. 9, 341–349 (2023). https://doi.org/10.1007/s40831-023-00657-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40831-023-00657-6