Abstract

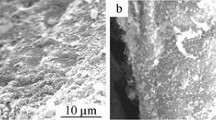

To develop a selective chlorination process for ilmenite ores with the aim of attaining a high chlorination ratio of Fe and minimal Ti loss with low activation energy, the kinetics of the selective chlorination of Fe from ilmenite ore powders using a mixture of CO and Cl2 gases in a static bed reactor was investigated. Experiments were conducted using ilmenite ore powders in the ranges of 45–75 µm and 180–212 µm at 1073–1173 K. When the chlorination reactions proceeded at 1173 K for 60 min, 94.12% of the Fe and 2.18% of the Ti were removed from the ore. After the selective chlorination reactions, TiO2 with a porous microstructure was generated owing to the selective removal of Fe from the ore. The generated pores allowed the CO–Cl2 gas mixture to easily penetrate into the reaction interface. As a result, when the unreacted shrinking-core model was utilized, the rate-controlling step was chemical reaction at the interface. In addition, the activation energy was 49.879 kJ · mol−1 for the selective chlorination of ilmenite ore powders using the CO–Cl2 gas mixture at 1073–1173 K. The results demonstrate that minimal Ti loss and a high chlorination ratio of Fe are feasible when the selective chlorination of ilmenite ore powders is performed at 1173 K using a CO–Cl2 gas mixture in a static bed reactor.

Graphical Abstract

Similar content being viewed by others

Abbreviations

- d :

-

Particle size, (μm)

- R Fe :

-

Removal ratio of Fe, (%)

- R Ti :

-

Removal ratio of Ti, (%)

- T :

-

Absolute temperature, (K)

- E a :

-

Activation energy, (kJ · mol−1)

- C i :

-

Concentration of oxide i, (wt.%)

- w o :

-

Weight of ilmenite ore powders before reactions, (g)

- m o :

-

Concentration of Fe or Ti in ilmenite ore powders before reactions, (wt.%)

- w t :

-

Weight of residues after reactions for duration of time (t), (g)

- m t :

-

Concentration of Fe or Ti in residues after reactions for duration of time (t), (wt.%)

- X :

-

Fractional conversion, (–)

- t :

-

Reaction time, (min)

- k f :

-

Rate constant of the gas-film mass transfer, (min−1)

- k d :

-

Rate constant of the diffusion through the product layer, (min−1)

- k r :

-

Rate constant of the chemical reaction, (min−1)

- k :

-

Rate constant, (min−1)

- R :

-

Universal gas constant, (J · mol−1 · K−1)

- A :

-

Frequency factor, (min−1)

References

Housley KL (2007) Black sand, the history of titanium, 1st edn. Metal Management Aerospace Inc, Hartford, CT

Sohn H, Jung J (2016) Current status of ilmenite beneficiation technology for production of TiO2. J Korean Inst Resour Recycl 25:64–74. https://doi.org/10.7844/kirr.2016.25.5.64 (in Korean)

Filippou D, Hudon G (2020) Minerals, slags, and other feedstock for the production of titanium metal. Extractive metallurgy of titanium. Elsevier Inc., Amsterdam, pp 19–45

Free ML (2020) A brief introduction to production of titanium dioxide and titanium tetrachloride. Extractive metallurgy of titanium. Elsevier Inc., Amsterdam, pp 13–18

National minerals information Center (2022) Mineral commodity summaries 2022 data release: U.S. geological survey data release. https://doi.org/10.5066/P9KKMCP4

Sohn HY, Zhou L (1999) The chlorination kinetics of bene®ciated ilmenite particles by CO-Cl2 mixtures. Chem Eng J 72:37–42. https://doi.org/10.1016/S1385-8947(98)00139-9

Jung EJ, Kim J, Lee YR (2021) A comparative study on the chloride effectiveness of synthetic rutile and natural rutile manufactured from ilmenite ore. Sci Rep 11:4045. https://doi.org/10.1038/s41598-021-83485-6

Van Deventer JSJ (1988) Kinetics of the selective chlorination of ilmenite. Thermochim Acta 124:205–215. https://doi.org/10.1016/0040-6031(88)87023-0

Lee S, Park S, Sohn H (2019) Removal of iron from ilmenite through selective chlorination using coke and Cl2 Gas. Korean J Met Mater 57:146–153. https://doi.org/10.3365/KJMM.2019.57.3.146 (in Korean)

Rhee KI, Sohn HY (1990) The selective carbochlorination of iron from titaniferous magnetite ore in a Fluidized Bed. Metall Mater Trans B 21:341–347. https://doi.org/10.1007/BF02664202

Fuwa A, Kimura E, Fukushima S (1978) Kinetics of iron chlorination of roasted ilmenite ore, Fe2TiO5 in a fluidized-bed reactor. Metall Mater Trans B 9:643–652. https://doi.org/10.1007/BF03257213

Rhee KI, Sohn HY (1990) The selective chlorination of iron from ilmenite ore by CO-Cl2 mixtures: Part I. intrinsic kinetics. Metall Mater Trans B 21:321–330. https://doi.org/10.1007/BF02664200

Lakshmanan CM, Hoelscher HE, Chennakesavan B (1965) The kinetics of ilmenite beneficiation in a fluidised chlorinator. Chem Eng Sci 20:1107–1113. https://doi.org/10.1016/0009-2509(65)80114-2

Doraiswamy LK, Bijawat HC, Kunte MV (1959) Chlorination of ilmenite in a fluidized bed. Chem Eng Prog 55:80–88

Fouga GG, Pasquevich DM, Bohé AE (2007) The kinetics and mechanism of selective iron chlorination of an ilmenite ore. Trans Inst Min Metall C 116:230–238. https://doi.org/10.1179/174328507X163779

Kang J, Okabe TH (2013) Upgrading titanium ore through selective chlorination using calcium chloride. Metall Mater Trans B 44:516–527. https://doi.org/10.1007/s11663-013-9818-8

Kang J, Okabe TH (2013) Removal of iron from titanium ore through selective chlorination using magnesium chloride. Metall Mater Trans B 54:1444–1453. https://doi.org/10.2320/matertrans.M-M2013810

Kang J, Okabe TH (2016) Removal of iron from titanium ore by selective chlorination using TiCl4 under high oxygen chemical potential. Int J Miner Process 149:111–118. https://doi.org/10.1016/j.minpro.2016.02.014

Swaminathan K, Rao CS (1984) Chloridization beneficiation of ilmenite. Metall Mater Trans B 15:259–275. https://doi.org/10.1007/BF02667329

Athavale AS, Altekar VA (1971) Kinetics of selective chlorination of ilmenite using hydrogen chloride in a fluidized bed. Ind Eng Chem Process Des Dev 10:523–530. https://doi.org/10.1021/i260040a017

Barin I (1995) Thermochemical data of pure substances. VCH Verlagsgesellschaft mbH, Weinheim

HSC Chemistry (2011) Chemical reaction and equilibrium software with extensive thermochemical database and flowsheet simulation (Vers. 7.11). Outokumpu Research Oy (Pori, Finland)

Levenspiel O (1999) Chemical reaction engineering, 3rd edn. Wiley, New York

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

The contributing editor for this article was Il Sohn.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Park, SH., Lee, SY., Ring, R. et al. Removal of Fe from Ilmenite Ore Powders Through Selective Chlorination Using CO and Cl2 Gas Mixture at 1073–1173 K in a Static Bed. J. Sustain. Metall. 9, 160–171 (2023). https://doi.org/10.1007/s40831-022-00628-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40831-022-00628-3