Abstract

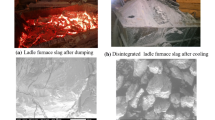

Ladle furnace (LF) slag plays an important role in modern steel making in terms of quality and productivity. The major challenge of using LF slag is its dusting problem. The polymorphic transformation of β-dicalcium silicate (monoclinic) to γ-dicalcium silicate (Orthorhombic) at about 450 °C is the leading cause of its disintegration. Hydration of slag, thermal shrinkage, and slower cooling are other reasons which are mainly responsible for slag powdering. The presence of dust particles due to disintegration not only creates a problem for its valorization but at the same time causes environmental issues. It becomes necessary for the steel makers to find out possible solutions to prevent such disintegration of slag. This review paper represents a detailed analysis of possible industrial solutions available for preventing of disintegration of LF slag and also will assist the steel operators for its effective utilization in major applications.

Graphical Abstract

Similar content being viewed by others

References

Pretorius E (2004) Fundamentals of Eaf and ladle slags, pp 1–73

YiLFirim IZ, Prezzi M (2011) Chemical, mineralogical, and morphological properties of steel slag. Adv Civ Eng 1–13

Yi H, Xu G, Cheng H (2012) An overview of utilization of steel slag. Proc Environ Sci 16:791–801

Motz H, Geiseler J (2001) Products of steel slags an opportunity to save natural resources. Waste Manage 21:285–293

Ozeki S (1997) Properties and usage of steel plant slag. Encosteel: steel for sustainable development. International Iron and Steel. Stockholm, pp 16–17

Guzzon M, Mapelli C (2007) Recycling of ladle slag in the EAF: improvement of the foaming behavior and decrease of the environmental impact. Rev Met Paris 104(4):171–178

Maghool F, Arulrajah A, Horpibulsuk S, Du YJ (2016) Laboratory evaluation of ladle furnace slag in unbound pavement-base/ subbase applications. J Mater Civ Eng. https://doi.org/10.1061/(ASCE)MT.1943-5533.0001724

Bocci E (2018) Use of ladle furnace slag as filler in hot asphalt mixtures. Constr BuiLF Mater 161:156–164

Makela M, Watkins G, Poykio R, Nurmesniemiet H, Dahl O (2012) Utilization of steel, pulp and paper industry solid residues in forest soil amendment: relevant physicochemical properties and heavy metal availability. J Hazard Mater 207–208:21–27

Wu ZH, Zou ZS, Wang CZ (2005) Application of converter slags in agriculture. Multipurpose Util Min Resour (in Chinese) 6:25–28

Rađenović A, Malina J, Soflić T (2013) Characterization of ladle furnace slag from carbon steel production as a potential adsorbent. Adv Mater Sci Eng 2013:1–6

Netinger I, Kesegic I, Guljas I (2011) The effect of high temperatures on the mechanical properties of concrete made with different types of aggregates. Fire Safety J 46:425–430

Tsakiridis PE, Papadimitriou GD, Tsivilis S, Koroneos C (2008) Utilization of steel slag for Portland cement clinker production. J Hazard Mater 152:805–811

Sun Y, Yao MS, Zhang JP, Yang G (2011) Indirect CO2 mineral sequestration by steelmaking slag with NH4Cl as leaching solution. Chem Eng J 173:437–445

Eloneva S, Tei S, Salminen J, Fogelholma CJ, Zevenhoven R (2008) Fixation of CO2 by carbonating calcium derived from blast furnace slag. Energy 33:1461–1467

Li LL, Li XY, Su XW, Ni W, Wang ZJ (2012) High strength of artificial reefs concrete made from steel slags. Met Mine (in Chinese) 3:158–162

Ghorai S, Mandal GK, Roy S, Minj RK, Agarwal A, Singh DP, Kumar A, Ramna RBV (2017) Treatment of LF slag to prevent powdering during cooling. J Min Metall Sec B-Metall 53:123–130

Liu SZ (1994) Application of slag in steelmaking. Steelmaking (in Chinese) 6:54–59

Jiang CS, Ding QJ, Wang FZ, Li C (2002) Chemical and physical characteristics of steel slag and its utilization progress. Overseas BuiLF Mater Sci Technol (in Chinese) 23(3):3–5

Chen MZ, Wei W, Wang H, Wu JH, Wu SP, Investigation of durability of steel slag asphalt pavement. WorLF BuiLF Mater (in Chinese) 31(4): 36–38

Sahoo PP, Nayak P, Ranjan R (2021) Prevention of ladle furnace slag disintegration through different slag additives. J Sustain Metall 7(1):115–125

Lin Y, Luo Q, Yan B, Fabritius T, Shu Q (2020) Effect of B2O3 addition on mineralogical phases and leaching behavior of synthetic CaO–SiO2–MgO–Al2O3–CrOx slag. J Mater Cycles Waste Manag 22(4):1208–1217

Branca TA, Colla V, Valentini R (2009) A way to reduce environmental impact of ladle furnace slag. Ironmak Steelmak 36(8):597–602

Engström F, Pontikes Y, Geysen D, Jones PT, Björkman B, Blanpain B (2011) Review: hot stage engineering to improve slag valorisation options. In: 2nd int. slag valoris. symp., pp 231–250

Sheshukov OY, Nekrasov IV, Mikheenkov MA, Egiazaryan DK, Lobanov DA (2017) Stabilization of refining slag by adjusting its phase composition and giving it the properties of mineral binders. Refract Ind Ceram 58(3):324–330

Saidani S, Smith A, El Hafiane Y, Tahar LB (2018) Re-examination of the β→γ transformation of Ca2SiO4. J Eur Ceram Soc 38(14):4756–4767

Iacobescu RI et al (2015) Ladle metallurgy stainless steel slag as a raw material in Ordinary Portland Cement production: a possibility for industrial symbiosis. J Clean Prod 112(1):872–881

Maiti SC, Ghoroi C (2017) Influence of catalytic nano-additive for stabilization of β-dicalcium silicate and its hydration rate with different electrolytes. Cem Concr Res 98:111–121

Behera N, Raddadi A, Ahmad S, Tewari N, Zeghaibi O (2016) Use of Al-killed ladle furnace slag in Si-killed steel process to reduce lime consumption improve slag fluidity. In: Proceedings of the 10th international conference on Advances in molten slags fluxes and salts, pp 1031–1039

Durinck D, Jones PT, Arnout S, Blanpain B, Stainless steel slag valorisation: on volume stability and disintegration. slag-valorisation-symposium.eu., pp 81–91

Manso JM, Losanez M, Polanco JA, Gonzalez JJ (2005) Ladle furnace slag in construction. J Mater Civ Eng 17(5):513–518

Nicolae M, Vılciu I, Zaman F (2007) X-ray diffraction analysis of steel slag and blast furnace slag viewing their use for road construction. UPB Sci Bull Series B 69(2):99–108

Qian GR, Sun DD, Tay JH, Lai ZY (2002) Hydrothermal reaction and autoclave stability of Mg bearing RO phase in steel slag. Br Ceram Trans 101(4):159–164

Tossavainen M, Engstrom F, Yang Q, Menad N, Larsson ML, Bjorkman B (2007) Characteristics of steel slag under different cooling conditions. Waste Manage 27(10):1335–1344

Memoli F, Mapelli C, Guzzon M (2007) Recycling of ladle slag in the EAF: a way to improve environmental conditions and reduce variable costs in steel plants. Iron Steel Tech 4:68–76

Varanasi SS, More VMR, Rao MBV, Alli SR, Tangudu AK, Santanu D (2019) Recycling ladle furnace slag as flux in steelmaking: a review. J Sustain Metall 5(4):449–462

Bharati S et al (2019) From waste to wealth: recycling the secondary resource from steel ladle as a flux in Si-killed steelmaking process. Ironmak Steelmak 46(8):794–799

Aminorroaya S, Edris H, Tohidi A, Parsi J, Zamani B, (2004) Recycling of ladle furnace slags. In: 2nd international conference on process development in iron and steel making (SCANMET II) Sweden MEFOS, pp 379–384

Seki A, Aso Y, Okubo M, Sudo F, Ishizaka K (1986) Development of dusting prevention stabilizer for stainless steel slag. Kawasaki Steel Giho 18:16–21

Gollapalli V, Rao S, Chenna T, Borra R, Soumya S (2020) Investigation on stabilization of ladle furnace slag with different additives. J Sustain Metall 6:121–131

Fletcher JG, Glasser FP (1993) Phase relations in the system CaO-B2O3-SiO2. J Mater Sci 28(10):2677–2686

Chan CJ, Kriven WM, Young JF (1992) Physical stabilization of the β→γ transformation in dicalcium silicate. J Am Ceram Soc 75(6):1621–1627

Yan P, Nie P, Huang S, Blanpain B, Guo M (2014) Sulphide capacity and mineralogy of BaO and B2O3 modified CaO-Al2O3 top slag. ISIJ Int 54(7):1570–1577

Durinck D, Arnout S, Mertens G, Boydens E, Jones PT, Elsen J, Blanpain B, Wollants P (2008) Borate distribution in stabilized stainless-steel slag. J Am Ceram Soc 91(2):548–554

Pontikes Y, Jones PT, Geysen D, Blanpain B (2010) Options to prevent dicalcium silicate-driven disintegration of stainless steel slags. Arch Metall Mater 55(4):1167–1172

Kim YJ, Nettleship I, Kriven WM (1992) Phase transformations in dicalcium silicate: II, TEM studies of crystallography, microstructure, and mechanisms. J Am Ceram Soc 75(9):2407–2419

Ghose A, Chopra S, Young JF (1983) Microstructural characterization of doped dicalcium silicate polymorphs. J Mater Sci 18(10):2905–2914

Christogerou A, Kavas T, Pontikes Y (2009) Use of boron wastes in the production of heavy clay ceramics. Ceram Int 35(1):447–452

Geysen D, Huang S, Lhoëst P, Cotton A (2010) Boron in stainless steel slags. In the 6th European Slag Conference. Madri, Spain

Huang S, Guo M, Jones PT, Blanpain B (2013) Fayalite slag modified stainless steel AOD-slag. IN: Proceedings of third international slag valorization symposium, pp 107–110

Kitamura S, Maruoka N (2009) Modification of stainless steel refining slag through mixing with nonferrous smelting slag. In: Jones PT, Geysen D, Guo M, Blanpain B (eds) First international slag valorization symposium, pp 140–143

Sakamoto N (2001) Effects of MgO-based glass addition on the dusting of stainless steel slag (development of control process of stainless steel slag dusting-3). Curr Adv Mater Process 14(4):939

Yang Q, Nedar L, Engstrom F, He M (2006) Treatments of AOD slag to produce aggregates for road construction. Aistech 2006. Ohio, USA, pp 573–583

Zhao H, Qi Y, Shi Y, Na X, Feng H (2013) Mechanism and prevention of disintegration of AOD stainless steel slag. J Iron Steel Res Int 20:26–30

Kuhn M, Drissen P, Schrey H (2000) Treatment of liquid steel slags. In: Proceedings of the 2nd European slag conference

Parker TW, Ryder WM (1942) Investigations on ‘falling’ blast furnace slag. J Iron Steel Inst 146:21–51

Harada G, Yen T, Tomari M (1979) Process for treating molten steel slag with red mud from the aluminum industry. US Patent, 4(179): 279

Iacobescu RI, Malfliet A, Machiels L, Pontikes Y (2014) (2014) “Stabilisation and microstructural modification of stainless steel converter slag by addition of an alumina rich by-product.” Waste Biomass Valorization 5(3):343–353

Mudersbach D, Kuehn M, Geiseler J, Koch K (2009) “Chrome immobilisation in EAF-slags from high-alloy steelmaking: tests at FEhS institute and development of an operational slag treatment process”, 1st International slag valorisation symposium. Belgium, Leuven, pp 101–110

Eriksson J, Björkman B (2004) MgO modifcation of slag from stainless steelmaking. In: International conference on molten slags fluxes and salts VII, Cape Town, pp 455–459

Yang Q, Engstrom F (2009) Modification study of steel slag to prevent the slag disintegration after metal recovery and to enhance slag utilization. In: 8th international conference on molten slags, fluxes and salts—MOLTEN 2009, pp 34–41

Stark J, Müller A, Schrader R, Rumpler KR (1980) Contributions to active belite cement, part 2: influence of cooling conditions of cement strength. Silikattechnik 31(2):50–52

Keith K, Craig P, Manning J (2001) Process for stabilizing and reusing ladle furnace slag. US Patent 6,189,818 B

Kriskova L, Pontikes Υ, Lietaert Κ, Pandelaers L (2011) “Effect of chemical composition and cooling rate on mineralogy and hydraulic properties of synthetic AOD slag”, to be presented in 12th International Conference and Exhibition of the European Ceramic Society. Stockholm, Sweden, pp 1–4

Erdmann R, Kesseler K, Mudersbach D, Kuehn M (2007) A new product: highly valuable slag from the OxyCup. Euroslag V - European Slag Conference, Luxembourg, pp 89–106

Author information

Authors and Affiliations

Corresponding author

Additional information

The contributing editor for this article was Il Sohn.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Dash, A., Chanda, P., Tripathy, P.K. et al. A Review on Stabilization of Ladle Furnace Slag-Powdering Issue. J. Sustain. Metall. 8, 1435–1449 (2022). https://doi.org/10.1007/s40831-022-00597-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40831-022-00597-7