Abstract

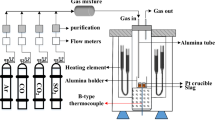

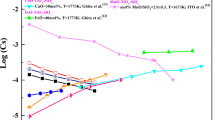

Employing low-quality raw materials to lower steel production costs is an effective way for many iron and steel enterprises to achieve the sustainable development in China. Meanwhile, this also raises higher requirement for the desulfurization ability of blast furnace slag with diverse components. In this work, the effect of Na2O on the sulfide capacity of CaO–SiO2-10wt% MgO-12wt% Al2O3-2wt% BaO slag was studied at 1773 K by employing the gas–slag equilibrium technique. The distribution of bridged oxygen (O0), non-bridged oxygen (O−), and free oxygen (O2−) in slag was analyzed by XPS. The results indicated that the sulfide capacity increased constantly with Na2O content rising from 0 to 5wt% due largely to an increase in the activity of O2−. Na+ would be consumed to compensate preferentially the [AlO4]-tetrahedron structural units to maintain electrical neutrality of molten slag, releasing some Ca2+ ions for sulfur stabilization. Assuming that the activity of O2− and the stability of S2− in molten slag were proportional to the activity of CaO and the activity coefficient of CaS, respectively, the increased range of the activity of CaO was larger than that of the activity coefficient of CaS on the whole, which improved the sulfide capacity of slag. XPS analysis indicated that the relative fraction of free oxygen and non-bridged oxygen increased gradually, and bridged oxygen showed a decreasing trend, which supported the changes of sulfide capacity based on the dominant effect for free oxygen on sulfide capacity.

Graphical Abstract

Similar content being viewed by others

References

Li ZL, Dai HC, Song JN, Sun L, Geng Y, Lu K, Hanaoka T (2019) Assessment of the carbon emissions reduction potential of China’s iron and steel industry based on a simulation analysis. Energy 183:279–290

Guo JL, Bao YP, Wang M (2018) Steel slag in China: treatment, recycling, and management. Waste Manage 78:318–330

Wang ZJ, Sohn I (2019) A review on reclamation and reutilization of ironmaking and steelmaking slags. J Sustain Metall 5:127–140

Hasanbeigi A, Arens M, Price L (2014) Alternative emerging ironmaking technologies for energy-efficiency and carbon dioxide emissions reduction: a technical review. Renew Sustain Energy Rev 33:645–658

Fincham CJB, Richardson FD (1954) The behaviour of sulphur in silicate and aluminate melts. Proc R Soc A223:40–62

Wang Y, Yang SF, Li JS, Wang F, Gu Y (2017) Cyclic use of ladle furnace refining slag for desulfurization. J Sustain Metall 3:274–279

Moosavi-Khoonsari E, Jung IH (2016) Thermodynamic modeling of sulfide capacity of Na2O-containing oxide melts. Metall Mater Trans B 47:2875–2888

Allertz C, Selleby M, Sichen D (2016) The effect of oxygen potential on the sulfide capacity for slags containing multivalent species. Metall Mater Trans B 47:3039–3045

Kim KD, Huh WW, Min DJ (2014) Effect of FeO and CaO on the sulfide capacity of the ferronickel smelting slag. Metall Mater Trans B 45:889–896

Park GH, Yang YB, Park JH (2011) Sulfide capacity of the CaO-SiO2-MnO slag at 1873K. ISIJ Int 51:1375–1382

Yan ZM, Lv XW, Pang ZD, He WC, Liang D, Bai CG (2017) Transition of blast furnace slag from silicate based to aluminate based: sulfide capacity. Metall Mater Trans B 48:2607–2614

Park Y, Min DJ (2016) Sulfide capacity of CaO-SiO2-FeO-Al2O3-MgOsatd. Slag ISIJ Int 56:520–526

Chan AH, Fruehan RJ (1989) The sulfur partition ratio with Fe-CSAT melts and the sulfide capacity of CaO-SiO2-Na2O-(Al2O3) slags. Metall Mater Trans B 20:71–76

Chan AH, Fruehan RJ (1986) The sulfur partition ratio and the sulfide capacity of Na2O-SiO2 slags at 1200℃. Metall Mater Trans B 17:491–496

Chol JY, Kim DJ, Lee HG (2011) Reaction kinetics of desulfurization of molten pig iron using CaO-SiO2-Al2O3-Na2O slag systems. ISIJ Int 41:216–224

Tong ZF, Qiao JL, Jiang XY (2017) Hot metal desulfurization kinetics by CaO-Al2O3-SiO2-MgO-TiO2-Na2O slags. ISIJ Int 57:245–253

Liu WG, Xing XD, Zuo HB (2020) Effect of TiO2 on viscosity and sulfide capacity of blast furnace slag containing barium. ISIJ Int 60:1886–1891

Liu WG, Zuo HB (2021) Effect of MnO and substituting CaO with BaO on the desulfurization ability of blast furnace slag. Metall Mater Trans B. https://doi.org/10.1007/s11663-021-02187-6

Ju JT, Liu WG, Xing XD, Wang J, An JL (2016) Sulphide capacity of CaO-SiO2-8%MgO-Al2O3-BaO slags ranging from 0% to 5% in BaO. Metall Res Technol. https://doi.org/10.1051/metal/2018077

Zhen YL, Zhang GH, Tang XL, Chou KC (2014) Influences of Al2O3/CaO and Na2O/CaO ratios on viscosities of CaO-Al2O3-SiO2-Na2O melts. Metall Mater Trans B 45:123–130

Wang ZJ, Sohn I (2018) Effect of substituting CaO with BaO on the viscosity and structure of CaO-BaO-SiO2-MgO-Al2O3 slags. J Am Ceram Soc 101:4285–4296

Wang WL, Shao HQ, Zhou LJ, Luo H, Wu HF (2020) Rheological behavior of the CaO-Al2O3-based mold fluxes with different Na2O contents. Ceram Int 46:26880–26887

Choi JS, Min DJ (2019) Cationic effect of ferrous ions on sulfide capacity of CaO-FetO-Al2O3-SiO2 slag system. Metall Mater Trans B 50:2758–2768

Waseda Y, Toguri JM (1998) The structure and properties of oxide melts. World Scientific, Singapore, pp 1–3

Duffy JA, Ingram MD (1971) Establishment of an optical scale for Lewis basicity in inorganic oxyacids, molten salts, and glasses. J Am Ceram Soc 93:6448–6454

Mills KC, Sridhar S (2013) Viscosities of ironmaking and steelmaking slags. Ironmak Steelmak 26:262–268

Zhang L, Zhai BY, Wang WL, Sohn I (2021) Effects of (CaO + BaO)/Al2O3 ratio on the melting, crystallization, and melt structure of CaO-Al2O3-10wt%-SiO2-based mold fluxes for advanced high-strength steels. J Sustain Metall. https://doi.org/10.1007/s40831-021-00358-y

Choi JS, Park Y, Lee S, Min DJ (2018) Cationic effect of charge compensation on the sulfide capacity of aluminosilicate slags. J Am Ceram Soc 101:2856–2867

Lee S, Min DJ (2018) Investigation of sulfide capacity of aluminosilicate slag based on ionic structure considerations. J Am Ceram Soc 101:634–643

Kim JB, Sohn I (2013) Influence of TiO2/SiO2 and MnO on the viscosity and structure in the TiO2-MnO-SiO2 welding flux system. J Non-Cryst Solids 379:235–243

Xing XD, Pang ZG, Zheng JL, Du YL, Ren S, Ju JT (2020) Effect of MgO and K2O on high-Al silicon-manganese alloy slag viscosity and structure. Minerals. https://doi.org/10.3390/min10090810

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant Number U1960205)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

The contributing editor for this article was Mansoor Barati.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, W., Chen, Y., Wang, J. et al. Sulfide Capacity of CaO–SiO2–MgO–Al2O3–BaO–Na2O Slag at 1773 K. J. Sustain. Metall. 7, 1169–1177 (2021). https://doi.org/10.1007/s40831-021-00411-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40831-021-00411-w