Abstract

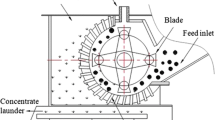

This paper presents the results of theoretical assessment and a preliminary experimental investigation of the modified pyrometallurgical processing of metallic granulate obtained after mechanical treatment of waste printed circuit boards (WPCBs). The studied two-step process included oxidation of metallic granulate followed by pyrometallurgical refining in a DC arc-furnace. In the investigated process, the oxygen bounded in metal oxides, obtained during the oxidation annealing of granulate, was used as a “solid” oxidizer for subsequent pyrometallurgical refining in a DC arc-furnace. According to the obtained results, the Cu content in the produced metallic phase (anodic copper) was 98.4% and is suitable for further electro-refining process. In addition, over 94% of Au was concentrated in metallic phase, suggesting that a high Au yield could be attained. However, owing to the distribution between slag phase and filter product, only 60% of Ag was collected in the metal phase. In-between metal and slag is the metal-oxide phase, containing Cu with metals impurities, such as Sn and Pb, which was obtained as well, and could be further treated using conventional processes for additional metal valorization. The investigated concept would allow substitution of the long-lasting oxygen blowing process and application of complicated pyrometallurgical reactors and create a feasible alternative for lower operating capacities.

Similar content being viewed by others

References

Reuter M, Hudson C, Van Schaik A, Heiskanen K, Meskers C, Hagelüken C (2013) Metal recycling: opportunities, limits, infrastructure. UNEP, Nairobi

Cui J, Zhang L (2008) Metallurgical recovery of metals from electronic waste: a review. J Hazard Mater 158(2–3):228–256

Chancerel P, Meskers C, Hagelüken C, Rotter S (2009) Assessment of precious metal flows during pre-processing of waste electrical and electronic equipment. J Ind Ecol 13:791–810

Antrekowitsch H, Potesser M, Spruzina W, Prior F (2006) Metallurgical recycling of electronic scrap. In: EPD Congress 2006, TMS, Warrendale, pp 12–16

Cucchiella F, D’Adamo I, Koh L, Rosa P (2016) A profitability assessment of European recycling processes treating printed circuit boards from waste electrical and electronic equipments. Renew Sust Energ Rev 64:749–760

Khaliq A, Rhamdhani MA, Brooks G, Masood S (2014) Metal extraction processes for electronic waste and existing industrial routes: a review and Australian perspective. Resources 3(1):152–179

Ghodrat M, Rhamdhani M, Brooks G, Masood S, Corder G (2016) Techno economic analysis of electronic waste processing through black copper smelting route. J Clean Prod 126:178–190

Forsen O, Aromaa J, Lundstrom M, (2017) Primary, copper smelter and refinery as recycling plant – A system integrated approach, Recycling 19 (2) https://doi.org/10.3390/recycling2040019

Schlesinger M, King M, Sole K, Davenport W (2011) Extractive metallurgy of copper. Elsevier, Oxford

Azakami T, Yazawa A (1976) Activity measurements of liquid copper binary alloys. Can Metall Q 15:111–122

Shuva M, Rhamdhani M, Brooks G, Masood S, Reuter M (2016) Thermodynamics data of valuable elements relevant to e-waste processing through primary and secondary copper production: a review. J. Clean Prod 131:795–809

Moats MS, Wang S, Kim D (2012) A review of the behavior and deportment of lead, bismuth, antimony and arsenic in copper electrorefining, T.T. Chen Symposium, TMS, pp 3–21

Namias J (2013) The future of electronic waste recycling in the United States: obstacles and domestic solutions. Columbia University, New York, http://www.seas.columbia.edu/earth/wtert/sofos/Namias_Thesis_07-08-13.pdf

Rhamdhani M, Ghodrat M, Brooks G, Masood S, Corder G, Haque N, Reuter M (2016) Evaluation of E-waste processing through secondary copper smelting, 8th annual high temperature processing symposium, Melbourne, https://doi.org/10.13140/rg.2.1.5033.7045

Friedrich B, Birich A, Borowski NPA, Diaz F, Flerus B, Trentmann A (2016) State of research in WEEE-recycling-metallurgical challenges and perspectives, conference: “WEEE-closing the loop. Next steps in recycling”, EIT KIC raw materials idea camp, Aachen, https://doi.org/10.13140/rg.2.2.30674.96966

Roine A. (2006) HSC Chemistry® v 6.12, Outotec Research Oy Center, Pori

Acknowledgements

The presented research was supported by Ministry of Education, Science and Technological Development, Republic of Serbia, project “Innovative synergy of by-products, waste minimization and cleaner production in metallurgy,” No. TR34033.

Author information

Authors and Affiliations

Corresponding author

Additional information

The contributing editor for this article was Bernd Friedrich.

Rights and permissions

About this article

Cite this article

Kamberović, Ž., Ranitović, M., Korać, M. et al. Pyro-Refining of Mechanically Treated Waste Printed Circuit Boards in a DC Arc-Furnace. J. Sustain. Metall. 4, 251–259 (2018). https://doi.org/10.1007/s40831-018-0167-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40831-018-0167-3