Abstract

CSIRO is developing the method of gamma activation analysis (GAA) for the rapid, non-destructive analysis of gold and other metals in mineral ores. Samples are irradiated with high-energy X-rays produced using a linear electron accelerator, resulting in activation of target elements. The gamma-rays emitted during the decays of the radioactive products of these activation reactions can be analyzed to determine the sample composition. Both the incident X-rays and emitted gamma-rays are sufficiently penetrating to allow large, heterogeneous samples to be analyzed directly without sampling or pre-treatment. We have recently conducted a preliminary study to investigate the application of the GAA method to the analysis of bulk electronic and automotive waste materials supplied by the SMaRT Centre at the University of New South Wales. The electronic waste gold contents vary from 80 to more than 800 parts-per-million (ppm), and silver contents range from 250–350 ppm; no gold or silver is observed in the automotive waste material. Consequently, the metal value of these waste materials is highly variable and can reach up to US$30,000 per tonne. Qualitative analysis demonstrates that the GAA method is capable of detecting a range of other economically and environmentally important elements in these samples, including copper, bromine, tin, lead, and tantalum. The speed and simplicity of the GAA method make it well suited to rapid waste characterization.

Similar content being viewed by others

Introduction

Electronic or e-waste is an umbrella term covering discarded electrical and electronic equipment that has reached the end of its life cycle, cannot be reused, and has ceased to be of any value to its owner. In 2014, around 41.8 million metric tonnes of e-waste was produced worldwide, with 468,000 metric tonnes produced in Australia alone. The amount of e-waste being produced around the world is expected to grow by 4–5 % each year up to 2018 [1]. E-waste is the fastest growing form of waste in Australia, with the rate of production currently increasing 3 times more quickly than any other waste type [2].

E-waste covers an extensive range of products from large white goods through to small personal electronic devices. A wide variety of e-waste products results in an extremely heterogeneous physical composition. E-waste can contain many metals in differing concentrations that can be recyclable, hazardous, or precious [3]. The most common metals by weight fraction include iron, copper, aluminum, nickel, zinc, and tin. Hazardous substances in e-waste include lead, mercury, arsenic, cadmium, and beryllium, among others. Precious metals such as gold, silver, and palladium are also found in small quantities, generally parts-per-million levels, but may constitute a significant fraction of the recycling value. Motives for recycling e-waste include reducing landfill volumes, preventing the leaching of toxic substances such as lead and mercury into the environment, and the recovery of valuable resources.

The value of e-waste can vary greatly depending on its metal content. Hagelüken and Buchert [4] and Hagelüken [5] determined average metal contents of e-waste derived from mobile phones, computer circuit boards, and television circuit boards. Using current (Sep. 2015) metal prices sourced from the metalprices.com website, we have calculated both the overall metal values of these different e-waste streams and the contributions from individual elements. These results are shown in Table 1.

It is immediately apparent that the metal value of e-waste is dominated by the precious metal content, especially gold and palladium. Only in materials relatively deficient in precious metals does copper make a significant contribution. The value of the other metals is generally low. As the precious metal content of different e-waste streams is so variable, the overall metal value also varies by more than a factor of 10.

Printed circuit boards (PCBs) form an important component of e-waste. PCBs typically comprise non-metals (plastics, epoxy, resins, and glasses) and metals (mainly copper, tin, iron, lead, and nickel, with parts-per-million concentrations of precious metals). Several of these metals may be present at significantly higher levels than conventional ore deposits, making PCBs a particularly interesting resource for recycling. Table 2 shows the comparison of typical concentrations of some metals found in PCBs with levels in commercial ores, with data taken from Bizzo et al. [6] and Viet et al. [7]. Concentrations of copper and gold are typically one and two orders of magnitude higher, respectively, in PCBs than in ore deposits.

When vehicles are recycled, approximately 75 % of material is separated, including lubricants, tyres, metals, and plastics. The remaining fraction is mechanically processed to produce ASR, a complex and highly heterogeneous mixture comprising plastics, rubber and elastomers, textiles, and metals and glass. The waste may also contain toxic and hazardous materials including chlorine and sulfur compounds, contaminated oil, polyvinyl chloride (PVC), and toxic metals. One study found that ASR samples contained up to 2930 ppm of copper, 550 ppm of nickel, 10,200 ppm of lead, and 13,200 ppm of zinc, making it unsuitable for some landfills [8].

A method capable of accurately analyzing the metal content of waste samples would find widespread application, both for valuing waste prior to recycling and verifying levels of hazardous metals before final disposal. The heterogeneous nature of e-waste and ASR, and the need for automated analysis of large numbers of samples to support industrial-scale recycling present particular challenges.

Rapidly and accurately assaying high-value elements in bulk samples is also important for the minerals industry. The method of gamma activation analysis (GAA) has been recognized as one solution [9–11] to this problem. A complement to the more commonly used neutron activation analysis, GAA involves irradiating samples with a high-energy X-ray beam to induce nuclear reactions in target elements. This induced radioactivity can be measured and related back to the elemental composition of the sample being analyzed.

Our work [12] has focused on improving the sensitivity and accuracy of the GAA method, particularly for the analysis of trace elements such as gold. In this preliminary study, we explore the application of the GAA technique to the analysis of gold, silver, and other elements in waste materials.

We particularly concentrate on activation reactions with very short half-lives that allow analysis to be completed in a few minutes. A secondary advantage of using short half-life reactions is that residual activity of samples after analysis is very low. For example, surface dose rates are generally unmeasurable above natural background about 1 hour after the measurement process is completed, and calculated radioisotope levels are below recommended clearance levels [13].

Electronic and Automotive Waste Samples

Electronic waste primarily consists of PCBs, solder, and electronic components. PCBs comprise a substrate material with copper layers on one or both surfaces, etched to form conductive tracks. Electronic components may be mounted on one or both sides of the board. Multi-layer boards are also commonly encountered, which include additional internal copper conducting layers to facilitate more complex circuit layouts.

Substrates for circuit board construction comprise a stiffening material bonded with a resin; fire retardants, often bromine-based, may also be added. Older, lower-cost substrate materials use cellulose-paper as the stiffening material and a phenolic or epoxy resin. The most commonly used substrate material, known as FR4, is a fiber-glass epoxy-resin composite. The electronic components mounted onto the circuit boards are made from a wide range of materials, including many metals and ceramics. Precious metals commonly used in the fabrication of these components include gold, silver, the platinum group elements (including platinum, palladium, ruthenium, rhodium, and iridium), and tantalum. The solder used to connect components to the circuit board may contain significant concentrations of lead, tin, copper, silver, bismuth, indium, zinc, and antinomy.

The electronic waste samples used for this study were sourced from the recycling unit of the University of New South Wales in Sydney, Australia. Three samples of randomly selected PCBs from discarded computer monitors and processing units were chosen.

Sample (a) was taken from a cathode ray tube (CRT) monitor. This was a single-sided, paper/resin laminate PCB. The entire board was shredded using a knife mill into approximately 5 mm pieces. Sample (b) was taken from a PCB inside a flat-panel LCD monitor. It was a double-sided board with a polymer substrate. Sample (c) was taken from a computer motherboard; it had a multi-layer, fiber-glass-based construction. Samples 2 and 3 were found to be too hard to shred using the knife mill, so the boards were manually broken into pieces measuring about 10 mm.

The fourth sample chosen for testing was automotive shredded residue (ASR), sourced from OneSteel Recycling based in Newcastle, NSW, Australia. The material received had a particle top size of approximately 5 mm and was measured as received.

Figure 1 shows the electronic waste and ASR samples in the form in which they were analyzed.

Sample Measurements Using Gamma Activation Analysis

The Gamma Activation Analysis (GAA) Method

The GAA process involves irradiating samples with an intense, high-energy X-ray beam. The maximum energy of the beam may vary from a few to a few tens of MeV. The beam is produced by accelerating electrons onto a metal target, resulting in the production of Bremsstrahlung photons with energies ranging up to the electron beam energy. X-rays of sufficient energy can induce a variety of nuclear reactions in target elements in the sample. If the isotopes produced in these reactions are radioactive, their decay products can be measured and counted to determine the composition of the sample.

As the threshold energy varies from reaction to reaction, and the radioisotope products have a wide range of half-lives, there is considerable flexibility to ‘tune’ the GAA method for different elements by selecting the energy of the incident electron beam, and the durations of the irradiation and measurement periods.

The two most important classes of X-ray-induced nuclear reactions are isomer formation and neutron emission. In the former case, a nucleus is resonantly excited from its ground state to an excited state. Normally, these excited nuclear states decay very quickly, with half-lives of nanoseconds or less. However, states with large spin differences from the ground state can have half-lives ranging from fractions of a second to many years. A neutron emission reaction can occur when an X-ray with energy above the neutron binding energy is absorbed by the target nucleus. The excited nucleus can then emit a neutron, potentially resulting in a radioactive daughter isotope.

After a period of irradiation, the sample is transferred to a measurement station comprising one or more detectors. These detectors are used to count gamma-rays emitted by the decays of radioactive nuclei in the sample. Different radioactive nuclei emit gamma-rays with specific energies, providing a characteristic elemental signature.

If a sample contains m grams of a particular isotope, then the number of detected gamma-rays resulting from activation and subsequent decay of that isotope is given by

where N A is Avogadro’s number, M is the relative atomic mass of the isotope in question, the integral over incident X-ray energy E runs from the reaction threshold energy ET to the maximum X-ray energy E 0, and \( \sigma \left( E \right) \) and \( \phi \left( E \right) \) are, respectively, the reaction cross section and average X-ray flux inside the sample volume. The radioisotope decay rate r is given by \( \ln \left( 2 \right)/t_{1/2}, \) where t 1/2 is the isotope half-life. Parameters t i, t c, and t m are, respectively, the durations of the irradiation, cooling or transfer, and measurement periods. Finally, pγ and pd are the probabilities of gamma-ray emission and detection.

Measurement Details

The GAA measurements were carried out at a facility in Ottawa, Canada, operated by Mevex Corp., a manufacturer of high-energy, high-power electron accelerators used for industrial irradiation and sterilization.

The electron linear accelerator (LINAC) used in this work is operable to produce an electron beam with energies between 6.5 and 13 MeV, with a maximum beam power of 4.5 kW. The LINAC is housed in a massive steel shield to protect both operators and sensitive electronic equipment from the prodigious levels of radiation produced. An aperture in the shield allows entry and egress of samples, which are automatically transferred using a computer-controlled pneumatic piston. A shielded detector station is positioned immediately outside the shield, comprising an 80-mm-diameter, 30-mm-thick high-resolution hyper-pure germanium ‘BEGe’ detector manufactured by Canberra. Signals from the detector are processed using a CAEN digital shaping amplifier which records the energy and arrival time of every gamma-ray.

For elements giving rise to short-lived activated products, it is convenient to repeatedly cycle the sample between irradiation and measurement positions, accumulating the resulting gamma-ray spectra to improve measurement precision.

Natural gold, which consists entirely of the isotope 197Au, has a convenient isomeric state at 409 keV. This state has a 7.73-s half-life and emits a 279-keV gamma-ray in 70 % of all decays. Together with a substantial activation cross section, this combination of factors makes GAA a particularly sensitive measurement technique for gold. Both naturally occurring isotopes of silver, 107Ag and 109Ag, have isomeric states with half-lives shorter than one minute, producing gamma-rays with energies of 93 and 88 keV, respectively. Other elements with convenient, short-lived isomeric states include bromine, barium, and yttrium.

For analysis, the samples were loaded into transparent plastic jars with a diameter of 80 mm and a height of 65 mm. Samples remain in these jars throughout the irradiation and measurement process. The sample size is primarily limited by the diameter of the gamma-ray detector used. Measurement of larger objects, for example discarded computer equipment, would require the use of an array of detectors to provide complete coverage.

Measurements were conducted at two different accelerator energy settings. An energy of 8.5 MeV is convenient for exciting isomeric states. As the neutron-emission thresholds of most common elements are above 8.5 MeV, activation of the sample is minimized, improving sensitivity for trace constituents such as gold and silver. Samples were irradiated and measured for 20 s, with a transfer time of about 1.5 s. Five irradiation/measurement cycles were performed for each sample.

A second irradiation was conducted at an electron beam energy of approximately 12.5 MeV. This energy is sufficient to induce neutron emission from a wide range of elements, including copper, antinomy, lead, and tin. Samples were irradiated for 5 s and measured for 20 s, with 6 irradiation/measurement cycles used. Approximately, 30 min after the high-energy irradiation process, samples were remeasured for a further 10 min. This latter measurement allows weaker decays from longer-lived isotopes to be measured without interference from intense, short half-life products that dominate immediately after irradiation.

Figure 2 shows the plot of the gamma-ray energy spectra measured using activation energies of 8.5, 12.5 MeV (immediate), and 12.5 MeV (delayed) for electronic waste sample (a). Prominent gamma-ray emission lines arising from elements in the sample are labeled. Other lines in the spectra arise from elements in the structures used to support and transport the sample container.

Composition Analysis

Qualitative analysis—that is, identification of the presence of elements in the samples—is carried out straightforwardly by identification of prominent gamma-ray emission lines in the measured activation spectra. The ENSDF [14] library tabulates half-lives, nuclear level diagrams, and gamma-ray emission energies and probabilities for more than 3000 nuclei. The high resolution of the BEGe detector used in this experiment, typically 1–2 keV over the energy range of interest, makes it straightforward to identify the isotopes responsible.

In cases where more than one isotope can give rise to a particular gamma-ray emission line, determination of the decay half-life using the recorded time-stamp information can assist in identification. An important example is the 511 keV positron annihilation line, which is produced by all positron-emitting isotopes.

Quantitative analysis is carried out using Eq. 1, which relates the number of detected gamma-rays to the mass of a given isotope in the sample. Considering the factors appearing on the right-hand side of this equation, the nuclear mass, half-life, and gamma-ray emission probabilities are generally well known, and the irradiation, cooling, and measurement times can be straightforwardly measured. The cross sections for neutron-emission reactions are known in many cases [15], but cross sections for isomeric excitation reactions are in general poorly understood. Accurate calculation of the X-ray flux emitted by the source is difficult, as it depends on several hard-to-measure parameters such as the spread in electron beam energy. Finally, the gamma-ray detection probability is a function of the sample geometry, mass, and composition.

To overcome these sources of uncertainty, we use a hybrid simulation/empirical calibration method. First, a detailed simulation of the irradiation and measurement process is carried out using the EGSnrc Monte Carlo code [16], following the method described in [17]. The Monte Carlo approach tracks individual X-rays and gamma-rays through a detailed, 3-dimensional model of the analyzer, which includes the radiation source, sample, detector systems, and shielding and support structures. Gamma-rays depositing energy in the simulated detector volumes are recorded, building up a predicted spectrum that can be compared with experiment.

The model is used to calculate relative activation and detection responses for different elements, which enable corrections for variations in sample geometry and density to be made. When the activation measurements were carried out, a number of reference samples were also measured containing known levels of gold and silver. In the second step of the calibration, measured responses of these known samples are used to determine the overall normalization, effectively correcting for the uncertainties in the reaction cross section and X-ray flux.

Unfortunately, we did not have reference samples available with known concentrations of the other elements observed in the waste materials, which precludes a quantitative analysis. Inclusion of suitable reference materials is planned for a future round of measurements.

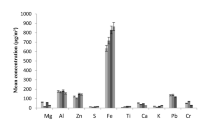

Table 3 summarizes the elements qualitatively detected in each of the four samples, along with the quantitative results for gold and silver. Statistical errors are indicated at one-standard deviation level; 3-standard deviation detection limits (DLs) are shown where elements are undetectable. Systematic errors arising from uncertainties in the Monte Carlo correction and calibration procedures are conservatively estimated to be 5 % relative for gold and 10 % relative for silver.

Discussion

All three electronic waste samples are found to have significant concentrations of gold and silver. The gold content of sample (c) at over 800 ppm is particularly large; at the current (Sep. 2015) price of US$1100 per ounce, the gold content of this material would be worth approximately US$30,000 per tonne. Silver contents of all three materials are also appreciable, but its much lower price makes the silver value correspondingly less. Other elements detected in one or more of the samples include barium, tantalum, yttrium, neodymium, and strontium. It should be noted that the sensitivity of the GAA method varies significantly from element to element.

The electronic waste samples (a) and (b) contain appreciable levels of lead and antimony, most likely present in the solder used to attach the electronic components. These elements are undetectable in waste sample (c), suggesting the use of a lead-free tin-silver-copper solder alloy or similar.

All three samples contain significant concentrations of bromine, most likely present as brominated flame retardants in the PCB substrate. We have previously demonstrated that the bromine content of FR4 circuit board substrate, for example, is approximately 5 % (unpublished study).

In contrast to the electronic waste samples, the ASR sample shows minimal activation at either 8.5 or 12.5 MeV. The only elements producing a significant signal are copper and barium. This is consistent with the waste mainly comprising plastic, glass, steel, and other materials formed from low atomic number elements, which have activation thresholds above the 12.5 MeV energy used in our experiments.

Conclusions

We have demonstrated that gamma activation analysis provides a powerful tool for analyzing both valuable and hazardous elements in waste materials. The advantages of GAA include the following:

-

True, bulk analysis of large and heterogeneous samples

-

Rapid measurement, with no sample preparation required, and results available in a few minutes

-

Excellent sensitivity for economically and environmentally important elements, including gold, silver, copper, tin, bromine, and lead.

The use of Monte Carlo-based radiation transport modeling allows calibration information to be readily transferred between different sample types, facilitating calibration of a GAA system using commercially available standards.

We are currently working to establish a commercial GAA facility in Australia for routine analysis of gold, silver, copper, and other elements in mineral ores. Such a facility would be equally applicable for valuing the metal content of samples of waste materials, and for monitoring processing and extraction operations.

References

Baldé CP, Wang F, Kuehr R, Huisman J (2015) The global e-waste monitor: 2014, United Nations University, IAS: SCYCLE, Bonn, Germany. http://i.unu.edu/media/ias.unu.edu-en/news/7916/Global-E-waste-Monitor-2014-small.pdf

Lewin J (2013) Recycling revolution report 2013, 1st edn. http://recyclingweek.planetark.org/documents/doc-1117-recycling-revolution-report-2013.pdf

Hagelüken C, Corti CW (2010) Recycling of gold from electronics: cost-effective use through “Design for Recycling”. Gold Bull 43(3):209–220

Hagelüken C, Buchert M (2008) The mine above ground: opportunities & challenges to recover scarce and valuable metals from EOL electronic devices. In: Proceedings of 7th international electronics recycling congress, Salzburg, 16–18 Jan 2008

Hagelüken C (2006) Improving metal returns and eco-efficiency in electronics recycling: a holistic approach for interface optimisation between pre-processing and integrated metals smelting and refining. In: Proceedings of the IEEE international symposium on electronics & the environment, San Francisco, 8–11 May 2006, pp 218–223

Bizzo WA, Figueiredo RA, Andrade VF (2014) Characterisation of printed circuit boards for metal and energy recovery after milling and mechanical separation materials. Materials 7:4555–4566

Viet HM, de Pereira CC, Bernardes AM (2002) Using mechanical processing in recycling printed wiring boards. JOM 54(6):45–47

Gonzalez-Fernandez O, Hidalgo M, Margui E, Carvalho ML, Queralt I (2008) Heavy metals’ content of automotive shredder residues (ASR): Evaluation of environmental risk. Environ Pollut (Barking, Essex: 1987) 153(2):476–482

Otvos J, Guinn V, Lukens J, Wagner C (1961) Photoactivation and photoneutron activation analysis. Nucl Instrum Methods 11:187–195

Burmistenko Y (1981) Gamma activation facility for fast determination of gold and accompanying elements in ore samples. Isotopenpraxis 17(6):241–243

Randa Z, Spacek B, Mizera J (2006) Fast determination of gold in large mass samples of gold ores by photoexcitation reactions using 10 MeV bremsstrahlung. J Radional Nucl Chem 271(3):603–606

Tickner J, O’Dwyer J, Roach G, Smith M, VanHaarlem Y (2015) Analysis of precious metals at parts-per-billion levels in industrial applications. Radiat Phys Chem. 116:43–47. doi:10.1016/j.radphyschem.2015.01.006

IAEA (1996) Clearance levels for radionuclides in solid materials, IAEA-TECDOC-855. http://www-pub.iaea.org/MTCD/publications/PDF/te_855_web.pdf

Tuli JK (2001) Evaluated nuclear structure data file, BNL-NCS-51655-01/02-Rev. http://www.nndc.bnl.gov/ensdf

IAEA (2000) Handbook on photonuclear data for applications, Cross sections and spectra, IAEA-TECDOC-Draft No 3. https://www-nds.iaea.org/photonuclear

Kawrakow I, Rogers D (2003) The EGSnrc code system: Monte Carlo simulation of electron and photon transport, NRCC Report PIRS-701

Bencardino R, Roach G, Tickner J, Uher J (2010) Efficient Monte Carlo simulation of delayed activation analysis experiments. Nucl Instrum Methods B 268(5):513–518

Acknowledgments

The authors would like to gratefully acknowledge the assistance of the staff at Mevex Corp for their generous assistance in setting up and operating the LINAC accelerator and sample-transfer system, and for hosting us at their Ottawa facility.

Author information

Authors and Affiliations

Corresponding author

Additional information

The contributing editor for this article was Yiannis Pontikes.

Rights and permissions

About this article

Cite this article

Tickner, J., Rajarao, R., Lovric, B. et al. Measurement of Gold and Other Metals in Electronic and Automotive Waste Using Gamma Activation Analysis. J. Sustain. Metall. 2, 296–303 (2016). https://doi.org/10.1007/s40831-016-0051-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40831-016-0051-y