Abstract

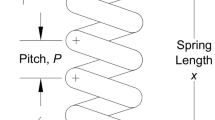

NiTiHf shape memory alloys are of high interest to the scientific community due to their high strength, excellent stability, and high transformation temperature. While many geometrical forms can be manufactured using NiTiHf, traditional springs are difficult to manufacture due to the material’s limited workability to wire form. Machined springs offer a great alternative to achieve a spring form using NiTiHf. Machined springs were fabricated from Ni50.3Ti29.7Hf20 (at.%) at spring rates of 87.6, 175.1, and 262.7 N mm−1. To manufacture the springs, a solid rod was cored out and a helix was machined into the tube. For each spring rate, two spring types were made: single–start and dual–start. The springs were subjected to constant-force thermal cycling tests, isothermal tests, and constant displacement thermal cycling tests. Computational modeling was used to determine the stress profiles within the springs. The NiTiHf springs showed very good stability, with less than 0.5 mm of change between the nineteenth and twentieth cycles. The machined springs were capable of actuation displacements up to 15.5 mm, over 50% extension from the original flexure length, superelastic stresses greater than 2.4 GPa, and tensile blocking forces ranging from 750 to more than 2000 N.

Similar content being viewed by others

Data availability

Data can be made available upon request.

References

Barros CDDR, Gomes JADCP (2021) Influence of Cu addition and autoclave sterilization on corrosion resistance and biocompatibility of NiTi for orthodontics applications. Mater Res. https://doi.org/10.1590/1980-5373-mr-2020-0369

Gil F, Planell J (1999) Effect of copper addition on the superelastic behavior of Ni-Ti shape memory alloys for orthodontic applications. J Biomed Mater Res 48(5):682–688

Iijima M, Ohno H, Kawashima I, Endo K, Mizoguchi I (2002) Mechanical behavior at different temperatures and stresses for superelastic nickel–titanium orthodontic wires having different transformation temperatures. Dent Mater 18(1):88–93

McCoy B (1996) Comparison of compositions and differential scanning calorimetric analyses of the new copper-Ni-Ti wires with existing Ni-Ti orthodontic wires, Thesis, available from The Ohio State University. Thesis completed 1996

Pun DK, Berzins DW (2008) Corrosion behavior of shape memory, superelastic, and nonsuperelastic nickel-titanium-based orthodontic wires at various temperatures. Dent Mater 24(2):221–227

Takagi T, Sutou Y, Kainuma R, Yamauchi K, Ishida K (2006) Effect of prestrain on martensitic transformation in a Ti46.4Ni47.6Nb6.0 superelastic alloy and its application to medical stents. J Biomed Mater Res Part B 76(1):179–183

Aiyer A, Russell NA, Pelletier MH, Myerson M, Walsh WR (2016) The Impact of nitinol staples on the compressive forces, contact area, and mechanical properties in comparison to a claw plate and crossed screws for the first tarsometatarsal arthrodesis. Foot Ankle Spec 9(3):232–240

Duerig T, Pelton A, Stöckel D (1999) An overview of nitinol medical applications. Mater Sci Eng A 273–275:149–160

Pelton AR, Duerig TW, Berg B, Hodgson D, Mertmann M, Mitchell M, Proft J, Wu M, Yang J (2005) Nitinol medical devices. Adv Mater Process 163:13

Szold A (2006) Nitinol: Shape-memory and super-elastic materials in surgery. Surg Endosc Other Interv Tech 20(9):1493–1496

Fezi K, Bigelow G, Benafan O (2020) Forging and hot rolling of high temperature actuator alloy NiTi20Hf. International Materials Applications & Technologies (IMAT), Cleveland, OH, Sept 2020

Wojcik CC (2009) Properties and heat treatment of high transition temperature Ni-Ti-Hf alloys. J Mater Eng Perf 18(5):511–516

Akgul O, Kockar B (2023) The effect of rolling process on the actuation fatigue behavior of Ni50Ti25Hf25 high temperature shape memory alloy. Shape Mem Superelasticity 3:1

Johnson AD, Martynov VV, Minners RS (1995) Sputter deposition of high transition temperature Ti-Ni-Hf alloy thin films. J Phys IV 5(8):83–88

Sanjabi S, Cao YZ, Barber ZH (2005) Multi-target sputter deposition of Ni50Ti50−XHfx shape memory thin films for high temperature microactuator application. Sens Actuators A Phys 121(2):543–548

Bigelow G, Benafan O, Garg A (2019) Towards the determination of shape set parameters for Ni50.3Ti29.7Hf20 shape memory alloy. The ASME 2019 conference on smart materials, adaptive structures and intelligent systems (SMASIS), Louisville, KY, Sept 2019

Canadinc D, Trehern W, Ozcan H, Hayrettin C, Karakoc O, Karaman I, Sun F, Chaudhry Z (2017) On the deformation response and cyclic stability of Ni50Ti35Hf15 high temperature shape memory alloy wires. Scr Mater 135:92–96

Ley NA, Wheeler RW, Benafan O, Young ML (2019) Characterization of thermomechanically processed high-temperature Ni-lean NiTi–20 at.% Hf shape memory wires. Shape Mem Superelasticity 5(4):476–485

Young AW, Wheeler RW, Ley NA, Benafan O, Young ML (2019) Microstructural and thermomechanical comparison of Ni-rich and Ni-lean NiTi-20 at.% Hf high temperature shape memory alloy wires. Shape Mem Superelasticity 5(4):397–406

Gantz F, Wall MT, Young ML, Forbes DJ (2022) Extending fatigue life of NiTiHf shape memory alloy wires through rapid thermal annealing. Shape Mem Superelasticity 8(4):439–451

Elahinia M, Shayesteh Moghaddam N, Amerinatanzi A, Saedi S, Toker GP, Karaca H, Bigelow GS, Benafan O (2018) Additive manufacturing of NiTiHf high temperature shape memory alloy. Scr Mater 145:90–94

Nematollahi M, Toker G, Saghaian SE, Salazar J, Mahtabi M, Benafan O, Karaca H, Elahinia M (2019) Additive manufacturing of Ni-rich NiTiHf20: Manufacturability, composition, density, and transformation behavior. Shape Mem Superelasticity 5(1):113–124

Toker GP, Nematollahi M, Saghaian SE, Baghbaderani KS, Benafan O, Elahinia M, Karaca HE (2020) Shape memory behavior of NiTiHf alloys fabricated by selective laser melting. Scr Mater 178:361–365

Nematollahi M (2022) Tailoring the properties of NiTi(Hf) alloys by laser powder bed fusion. PhD Thesis, available from University of Toledo. Thesis completed 2022

Benafan O, Gaydosh DJ (2020) Machined helical springs from NiTiHf shape memory alloy. Smart Mater Struct 29(12):125001

Wang J, Huang B, Gu X, Zhu J, Zhang W (2022) Actuation performance of machined helical springs from NiTi shape memory alloy. Int J Mech Sci 236:107744

Chen T, Zhang Y, Qiu S, Jiang J, Zhang Q, Zhang X (2022) Experiments and modeling of machined spring rotary actuators with shape memory alloys. Mater 15(19):6674

Saleeb AF, Padula SA, Kumar A (2011) A multi-axial, multimechanism based constitutive model for the comprehensive representation of the evolutionary response of SMAs under general thermomechanical loading conditions. Int J Plast 27(5):655–687

Saleeb AF, Dhakal B, Hosseini MS, Padula SA II (2013) Large scale simulation of NiTi helical spring actuators under repeated thermomechanical cycles. Smart Mater Struct 22(9):094006

Benafan O, Bigelow GS, Garg A, Noebe RD, Gaydosh DJ, Rogers RB (2021) Processing and scalability of NiTiHf high-temperature shape memory alloys. Shape Mem Superelasticity 7(1):109–165

ASTM International, E3097-23: standard test method for uniaxial constant force thermal cycling of shape memory alloys, 2023

Liesecke G (1933) Berechnung zylindrischer Schrauben-federn mit rechteckigem Drahtquerschnit. Z Ver Dtsch Ing 77:425–426

Göhner O (1932) Die Berechnung zylindrischer Schraubenfedern. Z Ver Dtsch Ing 76:269–272

Arnold SM, Saleeb AF, Wilt TE (1995) A modeling investigation of thermal and strain induced recovery and nonlinear hardening in potential based viscoplasticity. J Eng Mater Technol 117(2):157–167

Saleeb A, Arnold S, Castelli M, Wilt T, Graf W (2001) A general hereditary multimechanism-based deformation model with application to the viscoelastoplastic response of titanium alloys. Int J Plast 17(10):1305–1350

Saleeb AF, Dhakal B, Dilibal S, Owusu-Danquah JS, Padula SA (2015) On the modeling of the thermo-mechanical responses of four different classes of NiTi-based shape memory materials using a general multi-mechanism framework. Mech Mater 80:67–86

Fish J, Belytschko T (2007) A first course in finite elements. Wiley, West Sussex

Benafan O, Bigelow GS, Wood L, Luna HA (2022) Ruggedness evaluation of ASTM international standard test methods for shape memory materials: E3097 standard test method for mechanical uniaxial constant force thermal cycling of shape memory alloys. ASTM International, West Conshohocken

Benafan O, Noebe RD, Halsmer TJ (2016) Static rock splitters based on high temperature shape memory alloys for planetary explorations. Acta Astronaut 118:137–157

Acknowledgements

Funding from the NASA Aeronautics Research Mission Directorate (ARMD), Transformational Tools and Technologies (TTT) project is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Caltagirone, P.E., Ghezeljeh, P.N. & Benafan, O. Shape Memory NiTiHf Machined Helical Springs: Balancing Displacement and Force Output for Actuation. Shap. Mem. Superelasticity (2024). https://doi.org/10.1007/s40830-024-00479-9

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40830-024-00479-9