Abstract

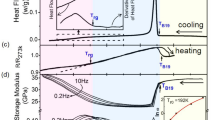

Strain glass, a conjugate state to martensite, is emerging as an important concept in our understanding of martensitic materials. It resolves many puzzling phenomena, and potentially provides a mechanism for novel properties that are absent in conventional martensitic alloys. This article reviews the progress of strain glass research from its fundamental characterization to the interesting properties to which it leads. We first give a brief introduction of the origin and evidence of strain glass, showing nano-domains as the microscopic basis for understanding its properties. Then we demonstrate that the strain glass state can exhibit many unexpected properties such as a shape-memory effect, superelasticity with a narrow hysteresis over a wide temperature range, high damping and low modulus over a wide temperature, Invar and Elinvar effects, elastocaloric effects, and low-field-triggered large magnetostriction. Lastly, some remaining challenges and opportunities, as well as some ongoing works about the strain glass are discussed.

Similar content being viewed by others

References

Sarkar S, Ren X, Otsuka K (2005) Evidence for strain glass in the ferroelastic-martensitic system Ti50−xNi50+x. Phys Rev Lett 95:205702

Ren X, Wang Y, Zhou Y, Zhang Z, Wang D, Fan G, Otsuka K, Suzuki T, Ji Y, Zhang J, Tian Y, Hou S, Ding X (2010) Strain glass in ferroelastic systems: Premartensitic tweed versus strain glass. Philos Mag 90(1–4):141–157

Ji Y, Wang D, Wang Y, Zhou Y, Xue D, Otsuka K, Wang Y, Ren X (2017) Ferroic glasses. npj Comput. Mater. 3:43

Ren X (2014) Strain glass and ferroic glass – Unusual properties from glassy nanodomains. Phys. Status Solidi B 251(10):1982–1992

Ji Y, Ren S, Wang D, Wang Y, Ren X (2018) Strain glasses, in: Frustrated Materials and Ferroic Glasses, Springer, Berlin.

Wang Y, Ren X, Otsuka K, Saxena A (2007) Evidence for broken ergodicity in strain glass. Phys Rev B 76(13):132201

Wang Y, Ren X, Otsuka K, Saxena A (2008) Temperature–stress phase diagram of strain glass Ti48. 5Ni51.5. Acta Mater 56(12): 2885–2896

Ji Y, Wang D, Ding X, Otsuka K, Ren X (2015) Origin of an isothermal R-martensite formation in Ni-rich Ti-Ni solid solution: Crystallization of strain glass. Phys. Rev. Lett. 114:055701

Wang Y, Zhou Y, Zhang J, Ding X, Yang S, Song X, Ren X, Otsuka K (2010) Evolution of the relaxation spectrum during the strain glass transition of Ti48. 5Ni51.5 alloy. Acta Mater 58(14): 4723–4729

Ren X, Kakeshita T, Fukuda T, Saxena A, Planes A (2012) Strain glass and strain glass transition, in: Disorder and Strain-Induced Complexity in Functional Materials. Springer Series in Materials Science Springer Berlin Heidelberg New York 148:201–225

Zhang Z, Wang Y, Wang D, Zhou Y, Otsuka K, Ren X (2010) Phase diagram of Ti50−xNi50+ x: Crossover from martensite to strain glass. Phys Rev B 81(22):224102

Hao Y, Ji Y, Zhang Z, Yin M, Liu C, Zhao H, Otsuka K, Ren X (2019) Strain glass in Ti50−xNi35+xCu15 shape memory alloys. Scripta Mater 168(15):71–75

Wang D, Zhang Z, Zhang J, Zhou Y, Wang Y, Ding X, Wang Y, Ren X (2010) Strain glass in Fe-doped Ti–Ni. Acta Mater 58(18):6206–6215

Zhou Y, Xue D, Ding X, Wang Y, Zhang J, Zhang Z, Wang D, Otsuka K, Sun J, Ren X (2010) Strain glass in doped Ti50(Ni50−xDx) (D= Co, Cr, Mn) alloys: Implication for the generality of strain glass in defect-containing ferroelastic systems. Acta Mater 58(16):5433–5442

Ji Y, Ding X, Lookman T, Otsuka K, Ren X (2013) Heterogeneities and strain glass behavior: Role of nanoscale precipitates in low-temperature-aged Ti48.7Ni51.3 alloys. Phys Rev B 87(10): 104110

Liang Q, Wang D, Zhang J, Ji Y, Ding X, Wang Y, Ren X, Wang Y (2017) Novel B19′ strain glass with large recoverable strain. Phys Rev Mater 1(3):033608

Zhou Y, Xue D, Ding X, Otsuka K, Sun J, Ren X (2009) High temperature strain glass in Ti50(Pd50−xCrx) alloy and the associated shape memory effect and superelasticity. Appl Phys Lett 95(15):151906

Wang Y, Gao J, Wu H, Yang S, Ding X, Wang D, Ren X, Wang Y, Song X, Gao J (2014) Strain glass transition in a multifunctional β-type Ti alloy. Sci Rep 4:3995

Wang Y, Huang C, Gao J, Yang S, Ding X, Song X, Ren X (2012) Evidence for ferromagnetic strain glass in Ni-Co-Mn-Ga Heusler alloy system. Appl Phys Lett 101(10):101913

Wang Y, Huang C, Wu H, Gao J, Yang S, Wang D, Ding X, Song X, Ren X (2013) Spontaneous strain glass to martensite transition in ferromagnetic Ni-Co-Mn-Ga strain glass. Appl Phys Lett 102(14):141909

Ma H, Yang J, Lu F, Qin F, Xiao W, Zhao X (2018) A FeNiMnC alloy with strain glass transition. Prog Nat Sci-Mater 28(1):74–77

Ren S, Xue D, Ji Y, Liu X, Yang S, Ren X (2017) Low-field-triggered large magnetostriction in iron-palladium strain glass alloys. Phys Rev Lett 119(12):125701

Yao Y, Yang Y, Ren S, Zhou C, Li L, Ren X (2012) Ferroelastic and strain glass transition in (1-x)(Bi0.5Na0.5)TiO3-xBaTiO3 solid solution. Europhys Lett 100(1): 17004

Ni Y, Zhang Z, Wang D, Wang Y, Ren X (2013) The effect of point defects on ferroelastic phase transition of lanthanum-doped calcium titanate ceramics. J. Alloys Compd 577:S468–S471

Ji Y, Zhang P, He L, Wang D, Luo H, Otsuka K, Wang Y, Ren X (2019) Tilt strain glass in Sr and Nb co-doped LaAlO3 ceramics. Acta Mater 168:250–260

Wang Y, Ren X, Otsuka K (2006) Shape memory effect and superelasticity in a strain glass alloy. Phys Rev Lett 97(22):225703

Qin F, Lu F, Chen Y, Yang J, Zhao X (2018) Deformation induced Elinvar behavior in Fe-Ni Invar alloy. Sci Bull 63(16):1040–1042

Wang D, Hou S, Wang Y, Ding X, Ren S, Ren X, Wang Y (2014) Superelasticity of slim hysteresis over a wide temperature range by nanodomains of martensite. Acta Mater 66:349–359

Zhang J, Wang Y, Ding X, Zhang Z, Zhou Y, Ren X, Otsuka K, Sun J, Song M (2011) Stress-induced strain glass to martensite (R) transition in a Ti50Ni44.5Fe5.5 alloy. Phys Rev B 83(17): 174204

Tang Z, Wang Y, Liao X, Wang D, Yang S, Song X (2015) Stress dependent transforming behaviors and associated functional properties of a nano-precipitates induced strain glass alloy. J Alloys Compd 622:622–627

Wang D, Ke X, Wang Y, Gao J, Wang Y, Zhang L, Yang S, Ren X (2012) Phase diagram of polar states in doped ferroelectric systems. Phys Rev B 86(5):054120

Wang D, Wang Y, Zhang Z, Ren X (2010) Modeling abnormal strain states in ferroelastic systems: the role of point defects. Phys Rev Lett 105(20):205702

Zhou Y, Xue D, Tian Y, Ding X, Guo S, Otsuka K, Sun J, Ren X (2014) Direct evidence for local symmetry breaking during a strain glass transition. Phys Rev Lett 112(2):025701

Kustov S, Salas D, Cesari E, Santamarta R, Mari D, Van Humbeeck J (2014) Structural anelasticity, elasticity and broken ergodicity in Ni–Ti shape memory alloys. Acta Mater 73:275–286

Ji Y, Ding X, Wang D, Otsuka K, Ren X (2015) Glass-ferroic composite caused by the crystallization of ferroic glass. Phys Rev B 92:241114(R)

Otsuka K, Wayman CM (1998) Shape memory materials. Cambridge University Press, Cambridge

Nii Y, Arima TH, Kim HY, Miyazaki S (2010) Effect of randomness on ferroelastic transitions: Disorder-induced hysteresis loop rounding in Ti-Nb-O martensitic alloy. Phys Rev B 82(21):214104

Wang DP, Chen X, Nie ZH, Li N, Wang ZL, Ren Y, Wang YD (2012) Transition in superelasticity for Ni55−xCoxFe18Ga27 alloys due to strain glass transition. Europhys Lett 98(4):46004

Niitsu K, Omori T, Kainuma R (2013) Stress-induced transformation behaviors at low temperatures in Ti-51.8Ni (at.%) shape memory alloy. Appl Phys Lett 102(23): 231915

Zhou Y, Xue D, Ding X, Otsuka K, Sun J, Ren X (2014) High temperature strain glass transition in defect doped Ti–Pd martensitic alloys. Phys Status Solidi B 251(10):2027–2033

Saito T, Furuta T, Hwang JH, Kuramoto S, Nishino K, Suzuki N, Chen R, Yamada A, Ito K, Seno Y, Nonaka T, Ikehata H, Nagasako N, Iwamoto C, Ikuhara Y, Sakuma T (2003) Multifunctional alloys obtained via a dislocation-free plastic deformation mechanism. Science 300(5618):464–467

Kwon HI, Kim IS (1995) A positron annihilation study of defects in extra high purity Ti with various deformation and annealing treatments. Scr Metall Mater 32(4):607

Kim H Y, Wei L, Kobayashi S, Tahara M, Miyazaki S (2013) Nanodomain structure and its effect on abnormal thermal expansion behavior of a Ti-23Nb-2Zr-0.7Ta-1.2O alloy. Acta Mater 61(13): 4874–4886

Ogawa Y, Ando D, Sutou Y, Koike J (2016) A lightweight shape-memory magnesium alloy. Science 353(6297):368–370

Acknowledgements

This work is supported by the National Natural Science Foundation of China (51701150, 51431007, 51621063, and 51831006), Program for Changjiang Scholars and Innovative Research Team in University (IRT_17R85), China Postdoctoral Science Foundation (2017M610637), and 111 Project 2.0 (BP2018008).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, C., Ji, Y. & Ren, X. Strain Glass and Novel Properties. Shap. Mem. Superelasticity 5, 299–312 (2019). https://doi.org/10.1007/s40830-019-00252-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40830-019-00252-3