Abstract

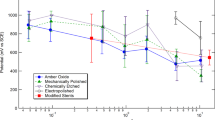

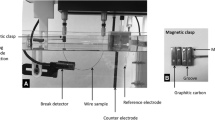

The corrosion resistance of thin NiTi wires in unstrained state and at 6% of pseudoelastic strain was determined by cyclic potentiodynamic polarization, considering a surface area of 2.3 cm2, equivalent to that of an actual minimally invasive implant. Surface finishing was carried out by mechanical polishing, electropolishing, and subsequent heat treatment in a salt bath furnace. Topography, microstructure, and composition of the respective surfaces were characterized in detail using light and electron microscopy, as well as glow discharge optical emission spectroscopy. Whereas breakdown below 1000 mV was observed for wires in mechanically polished condition in unstrained and strained state, wires in electropolished and electropolished + heat-treated condition exhibit no breakdown up to 1000 mV. Multiple testing reproduced uniform potentiodynamic polarization curves in unstrained and strained state. Accordingly, the observed formation of cracks in the surface oxide layer of wires in electropolished + heat-treated condition is concluded to be negligible in unstrained and strained state. Cause for the observed high performance of both the electropolished and the electropolished + heat-treated wires is apparently the smoothing of the initial surface that results in a homogeneous oxide layer even after heat treatment.

Similar content being viewed by others

References

Duerig TW (2002) The use of superelasticity in modern medicine. MRS Bull 27(2):101–104

Cattaneo G, Brauner C, Siekmeyer G, Ding A, Bauer S, Wohlschlogel M et al (2019) In vitro investigation of chemical properties and biocompatibility of neurovascular braided implants. J Mater Sci-Mater M 30(6):67

Undisz A, Schrempel F, Wesch W, Rettenmayr M (2009) In situ observation of surface oxide layers on medical grade Ni-Ti alloy during straining. J Biomed Mater Res Part A 88A(4):1000–1009

Freiberg KE, Bremer-Streck S, Kiehntopf M, Rettenmayr M, Undisz A (2014) Effect of thermomechanical pre-treatment on short- and long-term Ni release from biomedical NiTi. Acta Biomater 10(5):2290–2295

Shabalovskaya SA, Anderegg JW, Undisz A, Rettenmayr M, Rondelli GC (2012) Corrosion resistance, chemistry, and mechanical aspects of Nitinol surfaces formed in hydrogen peroxide solutions. J Biomed Mater Res B. 100B(6):1490–1499

Shabalovskaya SA, Rondelli GC, Undisz AL, Anderegg JW, Burleigh TD, Rettenmayr ME (2009) The electrochemical characteristics of native Nitinol surfaces. Biomaterials 30(22):3662–3671

Zhu L, Trépanier C, Pelton A, Fino JM (eds) Oxidation of nitinol and its effect on corrosion resistance. ASM Materials & Processes for Medical Devices Conference; 2003, 8–10 September; Anaheim, California

Racek J, Sittner P, Heller L, Pilch J, Petrenec M, Sedlak P (2014) Corrosion of NiTi wires with cracked oxide layer. J Mater Eng Perform 23(7):2659–2668

Racek J, Stora M, Šittner P, Heller L, Kopeček J, Petrenec M (2015) Monitoring tensile fatigue of superelastic NiTi wire in liquids by electrochemical potential. Shape Memory Superelasticity 1(2):204–230

Hessing C, Frenzel J, Pohl M, Shabalovskaya S (2008) Effect of martensitic transformation on the performance of coated NiTi surfaces. Mat Sci Eng a-Struct 486(1–2):461–469

Sullivan SJ, Dreher ML, Zheng J, Chen L, Madamba D, Miyashiro K et al (2015) Effects of oxide layer composition and radial compression on nickel release in nitinol stents. Shape Memory Superelasticity 1(3):319–327

Nagaraja S, Di Prima M, Saylor D, Takai E (2017) Current practices in corrosion, surface characterization, and nickel leach testing of cardiovascular metallic implants. J Biomed Mater Res B. 105(6):1330–1341

U.S. Department of Health and Human Services, Food and Drug Administration, Center for Devices and Radiological Health Services: Technical Considerations for Non- Clinical Assessment of Medical Devices containing Nitinol (2019)

ASTM F2129 (2019) Standard test method for conducting cyclic potentiodynamic polarization measurements to determine the corrosion susceptibility of small implant devices

ASTM G5 (2014) Standard reference test method for making potentiodynamic anodic polarization measurements

Freiberg KE, Hanke R, Rettenmayr M, Undisz A (2016) Surface preserving targeted preparation using focused ion beam demonstrated by the example of oxide layers on Ni-Ti alloys. Praktische Metallogr-Practical Metallogr 53(4):193–205

Undisz A, Hanke R, Freiberg KE, Hoffmann V, Rettenmayr M (2014) The effect of heating rate on the surface chemistry of NiTi. Acta Biomater 10(11):4919–4923

Shabalovskaya S, Anderegg J, Van Humbeeck J (2008) Critical overview of Nitinol surfaces and their modifications for medical applications. Acta Biomater 4(3):447–467

Acknowledgements

Andreas Keck from G. Rau GmbH is acknowledged for supplying the mechanically polished wire. Two of the authors (AU and KEF) gratefully acknowledge financial support by the German Research Foundation (DFG, UN 341/3-1 and Inst 275/391-1).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zende, S., Freiberg, K.E., Dorner, F. et al. Corrosion Resistance of Nitinol Wires After Deformation. Shap. Mem. Superelasticity 5, 346–351 (2019). https://doi.org/10.1007/s40830-019-00243-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40830-019-00243-4