Abstract

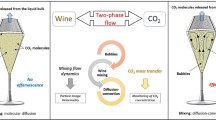

This study investigated the influence of the number of nucleation sites on the evolution of the dissolved CO2 concentration of beer contained in an etched glass comprising 0 to 70 etchings. Four identically shaped glasses were studied, three etched and one non-etched. We followed the temporal evolution of the liquid (i.e., beer) and gaseous (i.e., CO2) phases of the beer for each of them. The gaseous phase is monitored by measuring the evolution of the dissolved CO2 concentration in the beer once poured into the glass. Particle image velocimetry (PIV) techniques are used to quantify the mixing dynamics of the beer during the tasting. The results show that the CO2 concentration decreases approximately 3.7 times faster in the glass with 70 etchings than in the unetched glass. This study suggests a close link between the number of nucleation sites and the release of dissolved CO2 by different mechanisms: bubble bursting, molecular diffusion, and mass convection-diffusion, the latter being increased by liquid mixing mechanisms. On the one hand, too many bubbles will bother the consumer by causing a chemical sting and will quickly deplete the beer in dissolved gas. On the other hand, too few bubbles will not allow conveying the aromas to the surface and the consumer will judge the beer as too bland and not visually flattering, hence the need to find a compromise.

Similar content being viewed by others

References

Bamforth C (2000) J Inst Brew 106:229–238. https://doi.org/10.1002/j.2050-0416.2000.tb00062.x

Prins JT, Van Marle (1999) Foam formation in beer: some physics behind it. In: Proc Eur Brew Conv Congr Foam Symp. Amsterdam, Verlag Hans Carl, Getränke-Fachverlag: Nürnberg, pp. 26–36

Donadini G, Fumi MD, de Faveri MD (2011) J Inst Brew 117:523–533. https://doi.org/10.1002/j.2050-0416.2011.tb00500.x

Ono M, Hashimoto S, Kakudo Y, Nagami K, Kumada J (1983) J Am Soc Brew Chem 41:19–23. https://doi.org/10.1094/ASBCJ-41-0019

Liger-Belair G (2005) J Agric Food Chem 53:2788–2802. https://doi.org/10.1021/jf048259e

Clark R, Linforth R, Bealin-Kelly F, Hort J (2011) J Inst Brew 117:74–81. https://doi.org/10.1002/j.2050-0416.2011.tb00446.x

Meilgaard MC (1982) J Agric Food Chem 30:1009–1017. https://doi.org/10.1021/jf00114a002

Liger-Belair G, Conreux A, Villaume S, Cilindre C (2013) Food Res Int 54:516–522. https://doi.org/10.1016/j.foodres.2013.07.048

Tominaga T, Guimbertau G, Dubourdieu D (2003) J Agric Food Chem 51:1016–1020. https://doi.org/10.1021/jf020755k

Shafer NE, Zare RN (1991) Phys Today 44:48–52. https://doi.org/10.1063/1.881294

Polidori G, Beaumont F, Jeandet P, Liger-Belair G (2009) J Vis 12:275–282. https://doi.org/10.1007/BF03181866

Beaumont F, Popa C, Liger-Belair G, Polidori G (2012) JFV. 19 doi:https://doi.org/10.1615/JFlowVis ImageProc.2013005152

Beaumont F, Liger-Belair G, Polidori G (2015) Exp Fluids 56:170. https://doi.org/10.1007/s00348-015-2040-5

Beaumont F, Bogard F, Murer S, Polidori G (2022) Dynamics. 2, 326–335 https://doi.org/10.3390/dynamics2040018

Chandrashekar J, Yarmolinsky D, Von Buchholtz L, Oka Y, Sly W, Ryba NJ et al (2009) Science 326:443–445. https://doi.org/10.1126/science.11746

Dunkel T, Hofmann (2010) Angew Chem Int Ed 49:2975–2977. https://doi.org/10.1002/anie.200906978

Liger-Belair G et al (2008) Anal Chim Acta 621:30–37. https://doi.org/10.1016/j.aca.2007.10.054

Padet J (2005) in Convection thermique et massique: Principes généraux (Techniques de l’Ingénieur, p. 23

Perret DA, Bonhommeau G, Liger-Belair T, Cours A, Alijah (2014) J Phys Chem B 118:1839–1847. https://doi.org/10.1021/jp410998f

Beaumont F, Cilindre C, Abdi E, Maman M, Polidori G (2019) Curr Res Nutr Food Sci J 7:227–235. https://doi.org/10.12944/CRNFSJ.7.1.22

Liger-Belair G, Cilindre C (2021) ACS Omega 6:9672–9679. https://doi.org/10.1021/acsomega.1c00256

Beaumont F, Liger-Belair G, Bailly Y, Polidori G (2016) Exp Fluids 57:85. https://doi.org/10.1007/s00348-016-2180-2

Polidori G, Beaumont F, Jeandet P, Liger-Belair G (2008) J Vis 11:184–184. https://doi.org/10.1007/BF03181703

Buch M, Rakib M, Stambouli (2008) in Transfert de matière - Cinétique du transfert de matière entre deux phases, (Ed. Techniques Ingénieur,

Brogioli D, Vailati A (2000) Phys Rev E 63:012105. https://doi.org/10.1103/PhysRevE.63.012105

Beaumont F, Liger-Belair G, Polidori G (2019) Acta Mech 230:213–224. https://doi.org/10.1007/s00707-018-2311-3

Beaumont F, Liger-Belair G, Polidori G (2016) J Food Eng 188:58–65. https://doi.org/10.1016/j.jfoodeng.2016.05.012

Saint-Eve et al (2010) Food Quality and Preference. 21, 1026–1033 https://doi.org/10.1016/j.foodqual.2010.05.021

Pozo-Bayón M, Santos M, Martín-Álvarez PJ, Reineccius G (2009) Flavour Fragr J 24:226–233. https://doi.org/10.1002/ffj.1934

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Compliance with Ethical Standards

All authors certify that they have no affiliations with or involvement in any organization or entity with any financial interest or non-financial interest in the subject matter or materials discussed in this manuscript. The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Beaumont, F., Bogard, F., Murer, S. et al. New Insights on the Effect of Forced Laser-Etched Nucleation on the Unsteady Evolution of Two-Phase Flow in a Beer Glass. Exp Tech 48, 31–39 (2024). https://doi.org/10.1007/s40799-023-00644-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40799-023-00644-2