Abstract

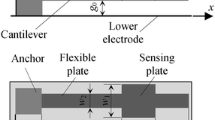

The paper presents the design, fabrication, and experimental validation of a new non-contact resonance-based measurement system to measure the thickness of ferromagnetic sheets and their alloys. The measurement system consists of a cantilever beam as a resonating structure with electromagnetic excitation and piezoelectric detection. The system measures the unknown thickness of a ferromagnetic sheet by measuring the resonance frequency of the cantilever beam resonator. The resonator vibrates at different resonance frequencies depending on the thickness of the ferromagnetic sheet. The electromagnet and the piezoelectric patch are connected with appropriate electronic circuitry for resonance excitation and detection of the resonator. The electronic circuitry will automatically track the resonance frequency of the measurement system for a variation in the ferromagnetic sheet thickness. A complete analytical model of the measurement system was developed and evaluated through experimentation. The analytical and experimental results are found to be in good agreement. The proposed measurement system is simple in design, compact, low cost, and its frequency output decrease linearly with an increase in thickness of the ferromagnetic sheets.

Similar content being viewed by others

References

Kim YH, Song SJ, Lee JK (2003) Simultaneous measurements of the ultrasonic wave velocity and thickness of a solid plate made from one side of the plate. Meas Sci Technol 14:13–16

Hsu DK, Hughes MS (1992) Simultaneous ultrasonic velocity and sample thickness measurement and application in composites. J Acoust Soc Am 92:669–675

Bramanti M (1992) A nondestructive diagnostic method based on swept frequency ultrasound transmission-reflection measurements. IEEE Trans Instrum Meas 41:490–494

Blitz J, Simpson G (1996) Ultrasonic Methods of Non-Destructive Testing, 1st edn. Chapman & Hall, London

Krautkrame J, Krautkrämer H (1990) Ultrasonic Testing of Materials, 4th edn. Springer Verlag, New York

Renaldas R, Rymantas K (2008) Ultrasonic thickness measurement of multilayered aluminum foam precursor material. IEEE Trans Instrum Meas 57:2846–2855

Kang BK, Kim SD, Lee SJ (1998) Magnetic flux sensor for control of thick steel plates. Sens Actuator A Phys 65:203–208

Nakane H, Sohara Y, Omori S (1991) Measuring the thickness of a thin-film conductor using solenoid coils. IEEE Trans Instrum Meas 40:429–432

Wei L, Yang Y, Kang Z, Zhihua F (2017) A thickness measurement system for metal films based on eddy current method with phase detection. IEEE Trans Ind Electron 64(5):3940–3949

Hongbo W, Wei L, Zhihua F (2015) Noncontact thickness measurement for metal films using eddy current sensors immune to distance variation. IEEE Trans Instrum Meas 64(9):2557–2564

Wei L, Hongbo W, Zhihua F (2016) Non-contact online thickness measurement system for metal films based on eddy current sensing with distance tracking technique. Rev Sci Instrum 87:045005

Luqman A, Cong W, Fan-Yi M, Yu-Chen W, Xiao T, Kishor Kumar A, Meng Z (2021) Simultaneous measurement of thickness and permittivity using microwave resonator-based planar sensor. Int J RF Microw. 1002/mmce.22794.

Zhen L, Zhaozong M, Changcheng W, Constantinos S, Zhijun C, Ping W, Andrew G (2022) A new microwave cavity resonator sensor for measuring coating thickness on carbon fiber composites. NDT & E Int J 126:102584

Suresh K, Uma G, Varun Kumar U, Santhosh Kumar BVMP, Umapathy M (2011) Piezoelectric based resonant mass sensor using phase measurement. Measurement J 44:320–325

Sujan Y, Uma G, Umapathy M (2017) Design and Modelling of a micro resonant pressure sensor. Microsyst Technol 23(5):1285–1293

Santhosh Kumar BVMP, Suresh K, Varun Kumar U, Uma G, Umapathy M (2012) Resonance based DC current sensor. Measurement J 45:369–374

Suresh K, Uma G, Umapathy M (2011) A new resonance-based method for the measurement of non-magnetic conducting sheet thickness. IEEE Trans Instrum Meas 60:3892–3897

Sujan Y, Vasuki B, Uma G, Ezhilarasi D, Suresh K (2012) Thickness sensor for ferromagnetic sheets. In: IEEE Sixth International Proceedings of Conference on Sensing Technology (ICST-2012), Kolkata, India (2012). https://doi.org/10.1109/ICSensT.2012.6461797.

Acknowledgements

The authors acknowledge BITS Pilani internal contingency grant and workshop fabrication facilities in the development of the proposed measurement system.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing Interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yenuganti, S., Paliwal, S. & Peparthi, M. Non-Contact Thickness Measurement System Using a Smart Cantilever Beam. Exp Tech 47, 1161–1167 (2023). https://doi.org/10.1007/s40799-022-00621-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40799-022-00621-1