Abstract

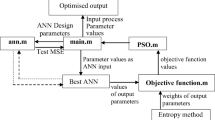

According to the application requirements of abrasive water jet emergency cutting steel, the cutting characteristics of different steels are analyzed from the aspects of cutting erosion section, cutting-in and cutting parameters by experimental research method. What’s more, the effects of operating parameters such as jet pressure, target distance, nozzle diameter, cutting angle, transverse speed, abrasive concentration and repeated cutting times on cutting-in are emphatically analyzed; Combined with the experimental data, AMPSO (Adaptive Mutation Particle Swarm Optimization)—BP (Back Propagation) neural network and AMPSO-SVM (Support Vector Machine) algorithm are designed to predict the cutting-in. The results showed that the erosion sections of different steels had similar morphology, and the trailing and roughness characteristics of the sections were closely related to the cutting-in; Compared with pre-mixing high pressure cutting, post-mixing ultra-high pressure cutting had deeper and finer slits, but there was a larger uncut area at the tail; Pressure, target distance and transverse speed were the key operating parameters affecting cutting-in. Both AMPSO-BP and AMPSO-SVM algorithm can predict cutting-in with mean relative errors of 10.03% and 6.34% respectively.

Similar content being viewed by others

References

Yin D-y, Chen X-c, Bao J-s (2020) Research on milling technology of 3D braided composites based on abrasive water jet[J]. J Mech Eng 56(1):1–8

Gao H, Yuan Y-m, Chen J-f et al (2020) Research progress of abrasive water jet blanking technology for aero-engine integral blade[J]. Acta Aeronaut Astronaut Sin 41(2):623319

Huang Z-w, Zhang S-k, Li G-s et al (2020) Breakage mechanism of high-temperature granite by abrasive liquid nitrogen jet[J]. Acta Pet Sin 41(5):604–614

Yuvaraj N, Pradeep KM, Mugilvalavan M et al (2020) Abrasive water jet machining process: a state of art of review[J]. J Manuf Process 49:271–322

Liu H-q, Wang Z-w, Cheng M (2018) Development and application status of high pressure water jet cutting technology[J]. Mach Tool Hydraul 46(21):173–179

Liu G-y, Yang Y, Xu H-y et al (2020) Analysis on uniformity of flow field for the new post-mixed abrasive water jet nozzle[J]. J Hunan Univ (Nat Sci) 47(10):56–66

Lin X-d, Lu Y-y, Tang J-r et al (2015) Numerical simulation of abrasive particles acceleration process in pre-mixed abrasive water jet[J]. J Vibration Shock 34(16):19–24 (47)

Lin X-d, Lu Y-y, Tang J-r et al (2015) Numerical simulation abrasive water jet breaking rock with SPH-FEM coupling algorithm[J]. J Vibration Shock 34(16):19–24 (47)

Chen X-c, Deng S-s, Guan J-f et al (2018) Characteristics and generation mechanism of metal damage morphology by abrasive water jet erosion[J]. Tribology 38(1):8–16

Duan R-h, Liu Z-q, Wang X et al (2020) Effect of abrasive water jet- plasma nitriding duplex treatment on friction property of 316 stainless steel surface[J]. Surface Technol 49(7):149–158

Libor M, Irena M, Francesco A et al (2018) Shape distortion reduction method for abrasive water jet (AWJ) cutting[J]. Precis Eng 53:194–202

Chen X-c, Deng S-s, Guo L-h et al (2016) Experimental research on X60 steel by portable abrasive water jet cutting system[J]. Mach Tool Hydraul 44(9):100–103

Wang S, Hu D, Yang F et al (2020) Exploring cutting front profile in abrasive water jet machining of aluminum alloys[J]. Int J Adv Manuf Technol. https://doi.org/10.1007/s00170-020-06379-3

Zhang T-f, Deng S-s, Zhang S-x et al (2015) Depth prediction model of high-pressure abrasive water jet cutting of Q235 steel[J]. Coal Mine Machinery 36(12):82–84

Guo J-h, Qi X-y, Wang D et al (2020) Influencing factors and depth prediction model of pre-mixed abrasive water jet cutting[J]. China Saf Sci J 30(1):101–106

Tang J-r, Lu Y-y, Sun H-j (2013) Study on visual BP neural network cutting model for abrasive water jet[J]. J Sichuang Univ (Eng Sci Ed) 45(3):104–169

Liao X-j (2020) Study on cutting mechanisms and quality improvement methods of abrasive water jet[D]. Jiangnan University, Jiangsu

Funding

Fund project: Project of Quartermaster Materials and Oil Department of General Logistics Department (YX213C208); Chongqing Natural Science Foundation of China (cstc2019jcyj-msxmX0268); Science and Technology Research Program of Chongqing Municipal Education Commission(KJQN202012906)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jiang, Y., Deng, S., Li, J. et al. Characteristic Analysis and Cutting-In Prediction of Abrasive Water Jet Emergency Cutting Steel. Exp Tech 47, 197–209 (2023). https://doi.org/10.1007/s40799-022-00585-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40799-022-00585-2