Abstract

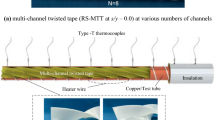

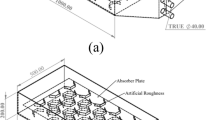

The current experimental study focuses on designing novel shapes of transverse turbulators to improve the performance of solar air heaters. Fourteen designs are derived from the original case having length × width × thickness of 30 mm × 15 mm × 0.8 mm. These turbulators are tested in a rectangular channel, and the thermal and hydraulic transport performances of the fitted channel are compared with those obtained for the vacant channel. Although the novel geometries may provide a weaker thermal characteristic through the channel, the penalty in the hydraulic characteristic is decreased significantly compared to the original shape, leading to better overall hydrothermal performances. It is found that the novel designs of transverse turbulators own lower values of heat transfer coefficient, that is ranging from 12.1% to 45.2%, whereas the pressure drop decreases within the range of 48%–91% at the studied Reynolds numbers (Re = 1643, 3286, and 4929). The results show that the Nusselt number ratio (Nufitted/Nuclear) gets reducing trend with increasing Re, while the friction factor ratio (ffitted/fclear) gets increasing trend. An appropriate tradeoff between thermal and hydraulic characteristics is established by using a specific design which presents minimum values of pressure drop and maximum values of the performance index. The highest index of 1.69 is recorded for this turbulator design at Re = 1643.

Similar content being viewed by others

Abbreviations

- A c :

-

frontal flow area (m2)

- A t :

-

total heat transfer area (m2)

- c p :

-

specific heat (J kg−1 K−1)

- D h :

-

hydraulic diameter (m)

- H :

-

height of channel (m)

- h :

-

heat transfer coefficient (W m−2 K−1)

- k :

-

thermal conductivity (W m−1 K−1)

- L :

-

length of channel (m)

- l :

-

length of turbulators (m)

- m :

-

mass flow rate (kg s−1)

- Q :

-

heat transfer rate (W)

- P :

-

perimeter (m)

- ∆p :

-

pressure drop (Pa)

- T :

-

temperature (K)

- t :

-

thickness of turbulators (m)

- u :

-

velocity (m s−1)

- W :

-

width of channel (m)

- w :

-

width of turbulators (m)

- ρ :

-

density (kg m−3)

- μ :

-

dynamic viscosity (Pa s)

- conv :

-

convection

- in :

-

inlet

- m :

-

mean

- out :

-

outlet

- w :

-

wall

- f :

-

Friction factor

- Nu :

-

Nusselt number.

- Pr :

-

Prandtl number

- Re :

-

Reynolds number

- OPI:

-

overall performance index

References

Awais M, Bhuiyan AA (2018) Heat transfer enhancement using different types of vortex generators (VGs): a review on experimental and numerical activities. Thermal Sci Eng Progress 5:524–545

Schubauer GB, Spangenberg WG (1960) Forced mixing in boundary layers. J Fluid Mech 8(1):10–32

Valencia A (1998) Numerical study of self-sustained oscillatory flows and heat transfer in channels with a tandem of transverse vortex generators. Heat Mass Transf 33:465–470

Nanan K, Thianpong C, Pimsarn M, Chuwattanakul V, Eiamsa-ard S (2017) Flow and thermal mechanisms in a heat exchanger tube inserted with twisted cross-baffle turbulators. Appl Thermal Eng 114:130–147

Sun Z, Zhang K, Li W, Chen Q, Zheng N (2020) Investigations of the turbulent thermal-hydraulic performance in circular heat exchanger tubes with multiple rectangular winglet vortex generators. Appl Thermal Eng 168:114838

Promvonge P, Skullong S (2020) Thermo-hydraulic performance in heat exchanger tube with V-shaped winglet vortex generator. Appl Thermal Eng 164:114424

Zheng N, Liu P, Shan F, Liu Z, Liu W (2017) Sensitivity analysis and multi-objective optimization of a heat exchanger tube with conical strip vortex generators. Appl Thermal Eng 122:642–652

Khoshvaght-Aliabadi M, Akbari MH, Hormozi F (2016) An empirical study on vortex-generator insert fitted in tubular heat exchangers with dilute cu–water nanofluid flow. Chinese J Chem Eng 24(6):728–736

Khoshvaght-Aliabadi M, Rahnama P, Zanganeh A, Akbari MH (2016) Experimental study on metallic water nanofluids flow inside rectangular duct equipped with circular pins (pin channel). Exp Thermal Fluid Sci 72:18–30

Lu G, Zhai X (2019) Effects of curved vortex generators on the air-side performance of fin-and-tube heat exchangers. Int J Thermal Sci 136:509–518

Han H, Wang S, Li S, Li Y, Wang S (2019) Numerical study of thermal and flow characteristics for a fin-and-tube heat exchanger with arc winglet type vortex generators. Int J Refrigeration 98:61–69

Modi AJ, Rathod MK (2019) Comparative study of heat transfer enhancement and pressure drop for fin-and-circular tube compact heat exchangers with sinusoidal wavy and elliptical curved rectangular winglet vortex generator. Int J Heat Mass Transf 141:310–326

Lu G, Zhai X (2018) Analysis on heat transfer and pressure drop of fin-and-oval-tube heat exchangers with tear-drop delta vortex generators. Int J Heat Mass Transf 127:1054–1063

Zeeshan M, Nath S, Bhanja D, Das A (2018) Numerical investigation for the optimal placements of rectangular vortex generators for improved thermal performance of fin-and-tube heat exchangers. Appl Thermal Eng 136:589–601

Awais M, Bhuiyan AA (2019) Enhancement of thermal and hydraulic performance of compact finned-tube heat exchanger using vortex generators (VGs): a parametric study. Int J Thermal Sci 140:154–166

Dang W, Nugud J, Lin Z-M, Zhang Y-H, Liu S, Wang L-B (2018) The performances of circular tube bank fin heat exchangers with fins punched with quadrilateral vortex generators and flow re-distributors. Appl Thermal Eng 134:437–449

N. Chimres, C-C. Wang, S. Wongwises, Optimal design of the semi-dimple vortex generator in the fin and tube heat exchanger, Int J Heat Mass Transf 120 (2018) 1173–1186

Samadifar M, Toghraie D (2018) Numerical simulation of heat transfer enhancement in a plate-fin heat exchanger using a new type of vortex generators. Appl Thermal Eng 133:671–681

Song KW, Tagawa T, Chen ZH, Zhang Q (2019) Heat transfer characteristics of concave and convex curved vortex generators in the channel of plate heat exchanger under laminar flow. Int J Thermal Sci 137:215–228

T. Ma, X. Lu, J. Pandit, S.V. Ekkad, S.T. Huxtable, S. Deshpande, Q-W. Wang, Numerical study on thermoelectric–hydraulic performance of a thermoelectric power generator with a plate-fin heat exchanger with longitudinal vortex generators, Appl Energy 185 (2017) 1343–1354

Khoshvaght-Aliabadi M, Jafari A, Sartipzadeh O, Salami M (2016) Thermal–hydraulic performance of wavy plate-fin heat exchanger using passive techniques: perforations, winglets, and nanofluids. Int Commun Heat Mass Transfer 78:231–240

Abdullah AS, Abou Al-sood MM, Omara ZM, Bek MA, Kabeel AE (2018) Performance evaluation of a new counter flow double pass solar air heater with turbulators. Sol Energy 173:398–406

Rajaseenivasan T, Srinivasan S, Srithar K (2015) Comprehensive study on solar air heater with circular and V-type turbulators attached on absorber plate. Energy 88:863–873

Acır A, Ata İ (2016) A study of heat transfer enhancement in a new solar air heater having circular type turbulators. J Energy Institute 89(4):606–616

Skullong S, Promthaisong P, Promvonge P, Thianpong C, Pimsarn M (2018) Thermal performance in solar air heater with perforated-winglet-type vortex generator. Sol Energy 170:1101–1117

Skullong S, Promvonge P, Thianpong C, Pimsarn M (2016) Thermal performance in solar air heater channel with combined wavy-groove and perforated-delta wing vortex generators. Appl Thermal Eng 100:611–620

Bezbaruah PJ, Das RS, Sarkar BK (2020) Overall performance analysis and GRA optimization of solar air heater with truncated half conical vortex generators. Sol Energy 196:637–652

Baissi MT, Brima A, Aoues K, Khanniche R, Moummi N (2020) Thermal behavior in a solar air heater channel roughened with delta-shaped vortex generators. Appl Thermal Eng 165:113563

Lu G, Zhai X (2019) Analysis on heat transfer and pressure drop of a microchannel heat sink with dimples and vortex generators. Int J Thermal Sci 145:105986

Al-Asadi MT, Al-damook A, Wilson MCT (2018) Assessment of vortex generator shapes and pin fin perforations for enhancing water-based heat sink performance. Int Commun Heat Mass Transfer 91:1–10

Khoshvaght-Aliabadi M, Deldar S, Hassani SM (2018) Effects of pin-fins geometry and nanofluid on the performance of a pin-fin miniature heat sink (PFMHS). Int J Mech Sci 148:442–458

Rashidi MM, Sadri M, Sheremet MA (2021) Numerical simulation of hybrid Nanofluid mixed convection in a lid-Driven Square cavity with magnetic field using high-order compact scheme. Nanomaterials 11(9):2250

Rashad AM, Rashidi MM, Lorenzini G, Ahmed SE, Aly AM (2017) Magnetic field and internal heat generation effects on the free convection in a rectangular cavity filled with a porous medium saturated with cu–water nanofluid. Int J Heat Mass Transf 104:878–889

Lakzian E, Masoudifar A, Saghi H (2017) A novel explicit equation for the friction factor prediction in the annular flow with drag-reducing polymer. European Phys J Plus 132:125

Mirzaie M, Lakzian E (2016) Natural convection of cu–water nanofluid near water density inversion in horizontal annulus with different arrangements of discrete heat source – sink pair. Advanced Powder Technol 27(4):1337–1346

ASHRAE (1977) Standard 93–77, Method of testing to determine the thermal performance of solar air heater, New York 1–34

Incropera FP, Dewitt DP, Bergman TL, Lavine AS (2007) Fundamentals of heat and mass transfer, sixth edn. John Wiley & Sons, New York

Kays WM, London AL (1984) Compact heat exchangers, 3rd edn. Kreiger Publishing, Melbourne

Webb RL, Kim NH (1994) Principle of enhanced heat transfer. Taylor Francis, New York

Kline SJ, McClintock FA (1953) Describing uncertainties in single-sample experiments. Mech Eng 75(1):3–8

Holman JP (2002) Heat transfer, ninth edn. McGraw-Hill, New York

Kakac S, Shah RK, Bergles AE (eds) (1983) Low Reynolds number flow heat exchanger. Hemisphere, New York, pp 75–108

Khoshvaght-Aliabadi M, Shabanpour H, Alizadeh A, Sartipzadeh O (2015) Experimental assessment of different inserts inside straight tubes: Nanofluid as working media. Chem Eng Process: Process Intensific 97:1–11

Khoshvaght-Aliabadi M, Zangouei S, Hormozi F (2015) Performance of a plate-fin heat exchanger with vortex-generator channels: 3D-CFD simulation and experimental validation. Int J Thermal Sci 88:180–192

Eiamsa-ard S, Somkleang P, Nuntadusit C, Thianpong C (2013) Heat transfer enhancement in tube by inserting uniform/non-uniform twisted-tapes with alternate axes: effect of rotated-axis length. Appl Thermal Eng 54(1):289–309

Rahimi M, Shabanian SR, Alsairafi AA (2009) Experimental and CFD studies on heat transfer and friction factor characteristics of a tube equipped with modified twisted tape inserts. Chem Eng Process: Process Intensific 48(3):762–770

Khoshvaght-Aliabadi M, Tatari M, Salami M (2018) Analysis on Al2O3/water nanofluid flow in a channel by inserting corrugated/perforated fins for solar heating heat exchangers. Renew Energy 115:1099–1108

Chang SW, Yang TL, Liou JS (2007) Heat transfer and pressure drop in tube with broken twisted tape insert. Exp Thermal Fluid Sci 32(2):489–501

Eiamsa-ard S, Seemawute P, Wongcharee K (2010) Influences of peripherally-cut twisted tape insert on heat transfer and thermal performance characteristics in laminar and turbulent tube flows. Exp Thermal Fluid Sci 34(6):711–719

Skullong S, Kwankaomeng S, Thianpong C, Promvonge P (2014) Thermal performance of turbulent flow in a solar air heater channel with rib-groove turbulators. Int Commun Heat Mass Transfer 50:34–43

Chokphoemphun S, Pimsarn M, Thianpong C, Promvonge P (2015) Heat transfer augmentation in a circular tube with winglet vortex generators. Chinese J Chem Eng 23(4):605–614

Acır A, Ata İ, Canlı ME (2016) Investigation of effect of the circular ring turbulators on heat transfer augmentation and fluid flow characteristic of solar air heater. Ex Thermal Fluid Sci 77:45–54

Pourramezan M, Ajam H (2016) Modeling for thermal augmentation of turbulent flow in a circular tube fitted with twisted conical strip inserts. Appl Thermal Eng 105:509–518

Khoshvaght-Aliabadi M, Baneshi Z, Khaligh SF (2017) Analysis on performance of nanofluid-cooled vortex-generator channels with variable longitudinal spacing among delta-winglets. Appl Thermal Eng 122:1–10

Lei Y, Zheng F, Song C, Lyu Y (2017) Improving the thermal hydraulic performance of a circular tube by using punched delta-winglet vortex generators. Int J Heat Mass Transf 111:299–311

Chamoli S, Lu R, Yu P (2017) Thermal characteristic of a turbulent flow through a circular tube fitted with perforated vortex generator inserts. Appl Thermal Eng 121:1117–1134

Liu H-L, Li H, He Y-L, Che Z-T (2018) Heat transfer and flow characteristics in a circular tube fitted with rectangular winglet vortex generators. Int J Heat Mass Transf 126:989–1006

Xu Y, Islam MD, Kharoua N (2018) Experimental study of thermal performance and flow behaviour with winglet vortex generators in a circular tube. Appl Thermal Eng 135:257–268

Ibrahim MM, Essa MA, Mostafa NH (2019) A computational study of heat transfer analysis for a circular tube with conical ring turbulators. Int J Thermal Sci 137:138–160

Nakhchi ME, Esfahani JA (2019) Numerical investigation of different geometrical parameters of perforated conical rings on flow structure and heat transfer in heat exchangers. Appl Thermal Eng 156:494–505

Zhai C, Islam MD, Simmons R, Barsoum I (2019) Heat transfer augmentation in a circular tube with delta winglet vortex generator pairs. Int J Thermal Sci 140:480–490

Acknowledgments

The authors thank Dr. S.M. Hassani for his assistance with the experiments, and Miss A. Salimi in revising the manuscript.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

There is no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Khosravi, M., Khoshvaght-Aliabadi, M. & Mortazavi, S. Hydrothermal Performance Augmentation of a Rectangular Channel Via Novel Designs of Transverse Turbulators: An Insight into Performance Improvement of Solar Air Heaters. Exp Tech 46, 889–903 (2022). https://doi.org/10.1007/s40799-021-00523-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40799-021-00523-8