Abstract

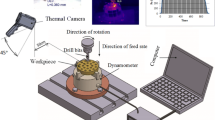

The low heat conduction values and high mechanical properties of stainless steels, which have high resistance to corrosion, make them difficult to be machined. Custom 450, a martensitic stainless steel alloy, is highly resistant to corrosion especially at high temperatures and is used in ammunition coolant tanks. Although there are studies on the machinability of stainless steel alloys in the literature, studies on the drillability of Custom 450 martensitic stainless steel are quite limited. For this reason, Custom 450 material was subjected to drilling experiments in the study with 4 different cutting speeds and 4 different feed rates using 4 different carbide drill bits without using coolant. In order to model and minimize the thrust force, drill bit temperature and burr height values, experiments and measurements were carried out using the L16 orthogonal arrays of Taguchi method. Drilling variables were optimized simultaneously by applying Taguchi-based Grey Relational Analysis (GRA) with the help of the data obtained from the experiments. Mathematical models have been developed by using the Response Surface Method (RSM) in order to predict the experimental results. It was observed that there was a significant increase in the thrust forces and burr heights with increasing values of the feed rate. The drill bit temperature was adversely affected by the increasing values of cutting speed. According to the analysis of variance, it was seen that the most effective control factors were 86.30% feed rate for thrust force, 97.52% cutting speed for temperature and 85.87% for burr height. Following the GRA, the feed rate was found to be the most important control factor with a value of 0.2921. Moreover, according to the results of multiple response optimizations, the most suitable parameters were identified as 15 m/min. Cutting speed, 0.005 mm/rev feed rate, and the drill bit number 4. The reliability of the developed mathematical model was confirmed with determination coefficients which are 98.34% for thrust forces, 99.78% for drill bit temperature and 98.54% for burr height.

Similar content being viewed by others

References

Kalpakjian S, Schmid S (2014) Manufacturing Engineering and Technology. 7th ed. Pearson Education Inc, Singapore, pp 625–665

Das R, Barik T (2014) An experimental study on the burr formation in drilling of aluminum channels of rectangular section. 5th International & 26th All India Manufacturing Technology, Design and Research Conference (AIMTDR); p 831–835

Kurt M, Kaynak Y, Bakır B, Köklü U, Atakök G, Kutlu L (2009) Experimental investigation and Taguchi optimization for the effect of cutting parameters on the drilling of Al 2024-t4 alloy with diamond like carbon (DLC) coated drills. 5. Uluslararası İleri Teknolojiler Sempozyumu (IATS’09), Karabük

Tonshoff HL, Spintig W, Konig W, Neises A (1994) Machining of holes developments in drilling techonolgy. Annals CIRP 43(2):551–560. https://doi.org/10.1016/S0007-8506(07)60501-0

Çakır A, Bahtiyar O, Şeker U (2014) Farklı soğutma şartları ile farklı kesme parametrelerinin AA7075 ve AA2024 alüminyum alaşımlarında delik delme işlemlerine etkisinin deneysel olarak incelenmesi. 16. Uluslararası Makina Tasarım ve İmalat Kongresi, İzmir

Yağmur S, Acır A, Şeker U, Günay M (2013) An experimental investigation of effect of cutting parameters on cutting zone temperature in drilling. J Fac Eng Archit Gazi Univ 28(1):1–6

Kakati AK, Chandrasekaran M, Mandal A, Singh AK (2011) Prediction of optimum cutting parameters to obtain desired surface in finish pass end milling of aluminium alloy with carbide tool using artificial neural network. World Acad Sci Eng Technol 5(9):1929–1935

Günay M, Meral T (2020) Modelling and multiresponse optimization for minimizing burr height, thrust force and surface roughness in drilling of ferritic stainless steel. Indian Acad Sci – Sådhanå 45:275. https://doi.org/10.1007/s12046-020-01490-3

Gaitonde VN, Karnik SR, Achyutha BT, Siddeswarappa B (2005) GA applications to RSM based models for burr size reduction in drilling. J Sci Industrial Researc 64(5):347–353

Kumar S, Rizvi Y, Kumar R (2018) A review of modelling and optimization techniques in turning processes. Int J Mech Eng Technol (IJMET) 9(3):1146–1156

Mondal N, Mandal S, Mandal MC (2020) FPA based optimization of drilling burr using regression analysis and ANN model. Measurement 152:1–10. https://doi.org/10.1016/j.measurement.2019.107327

Dörterler M, Şahin İ, Gökçe H (2019) A grey wolf optimizer approach for optimal weight design problem of the spur gear. Eng Optim 51(6):1013–1027. https://doi.org/10.1080/0305215X.2018.1509963

Özyürek D, Kalyon A, Yıldırım M, Tuncay T, Çiftçi İ (2014) Experimental investigation and prediction of wear properties of Al/SiC metal matrix composites produced by thixomoulding method using artificial neural networks. Mater Des 63:270–277. https://doi.org/10.1016/j.matdes.2014.06.005

Colligan K (1994) New tool drills both titanium and carbon composites. Am Mach 138(10):56–58

Kim D, Ramulu M (2005) Cutting and drilling characteristics of hybrid titanium composite laminate (HTCL). Proceedings of Materials and Processing Technologies for Revolutionary Applications Fall Technical Conference, Seattle

Lambert BK (1979) Prediction of force, torque and burr length in drilling titanium-composite materials. SME Technical Paper MR79–363

Bayraktar Ş, Turgut Y (2016) AL-5083 alaşımının frezelenmesinde kesme kuvveti, yüzey pürüzlülüğü ve çapak yüksekliğinin optimizasyonu. 7th International Symposium on Machining, Marmara University, İstanbul

Çiftçi İ, Gökçe H (2019) Optimisation of cutting tool and cutting parameters in machining of molybdenum alloys through the Taguchi method. J Fac Eng Archit Gazi Univ 34(1):201–213. https://doi.org/10.17341/gazimmfd.416482

Gökçe H, Çiftçi İ, Demir H (2018) Cutting parameter optimization in shoulder milling of commercially pure molybdenum. J Braz Soc Mech Sci Eng 40:360. https://doi.org/10.1007/s40430-018-1280-8

Abdelhafeez AM, Soo SL, Aspinwall DK, Dowson A, Arnold D (2015) Burr formation and hole quality when drilling titanium and aluminium alloys. Procedia CIRP 37:230–235. https://doi.org/10.1016/j.procir.2015.08.019

Patne HS, Kumar A, Karagadde S, Joshi SS (2017) Modeling of temperature distribution in drilling of titanium. Int J Mech Sci 133:598–610. https://doi.org/10.1016/j.ijmecsci.2017.09.024

Korkmaz ME, Meral T, Günay M (2018) Drillability analysis of AISI 420 martensitic stainless steel by finite element method. Gazi J Eng Sci 4(3):223–229. https://doi.org/10.30855/GJES.2018.04.03.009

Bayraktar Ş, Siyambaş Y, Turgut Y (2017) Delik delme prosesi: Bir araştırma. Sakarya Üniversitesi Fen Bilimleri Enstitüsü Dergisi 21(2):120–130

Meral G, Dilipak H, Sarıkaya M (2011) The modeling of drilling parameters effect on the hole quality in drilling of AISI 1050 material via multiple regression method. Electronic J Mach Technol 8(1):37–46

Dhar NR, Ahmed NT, Islam S (2007) An experimental investigation on effect of minumum quantity lubrication in machining AISI 1040 steel. Int J Mach Tool Manu 47:748–753. https://doi.org/10.1016/j.ijmachtools.2006.09.017

Gökçe H (2020) Investigation of drilling performance of copper material in terms of cutting force and tool temperature. El-Cezerî J Sci Eng 7(3):1039–1053. https://doi.org/10.31202/ecjse.730812

Bahçe E, Özel C (2014) Al-5005’in delinmesinde işleme parametrelerinin çapak boyutları üzerine etkilerinin deneysel incelenmesi. Makine Magazin 4:89–94

Aurich JC, Dornfeld D, Arrazola PJ, Franke V, Leitz L, Min S (2009) Burrs-analysis, control and removal. CIRP Annals- Manufact Technol 58(2):519–542. https://doi.org/10.1016/j.cirp.2009.09.004

Uzun H, Meral T, Günay M (2020) Modelling and optimization of burr height in fiber laser drilling of ferritic stainless steel. Manufact Technol Appl 1(2):32–39

Guo YB, Dornfeld DA (2000) Finite element modeling of burr formation process in drilling 304 stainless steel. J Manuf Sci Eng 122:612–619. https://doi.org/10.1115/1.1285885

Amini S, Alinaghian I, Lotfi M, Teimouri R, Alinaghian M (2017) Modified drilling process of AISI 1045 steel: a hybrid optimization. Eng Sci Technol Int J 20:1653–1661. https://doi.org/10.1016/j.jestch.2017.11.005

Balaji M, Murthy BSN, Rao NM (2016) Optimization of cutting parameters in drilling of AISI 304 stainless steel using Taguchi and ANOVA. Procedia Technol 25:1106–1113. https://doi.org/10.1016/j.protcy.2016.08.217

Çiçek A, Kıvak T, Ekici E (2015) Optimization of drilling parameters using Taguchi technique and response surface methodology (RSM) in drilling of AISI 304 steel with cryogenically treated HSS drills. J Intell Manuf 26:295–305. https://doi.org/10.1007/s10845-013-0783-5

Gaitonde VN, Karnik SR, Achyutha BT, Siddeswarappa B (2008) Taguchi optimization in drilling of AISI 316L stainless steel to minimize burr size using multi-performance objective based on membership function. J Mater Process Technol 202(1–3):374–379. https://doi.org/10.1016/j.jmatprotec.2007.08.013

Çaydaş U, Hasçalık A, Buytoz Ö, Meyveci A (2011) Performance evaluation of different twist drills in dry drilling of AISI 304 austenitic stainless steel. Mater Manuf Process 26:951–960. https://doi.org/10.1080/10426914.2010.520790

Mavi A (2018) Determination of optimum cutting parameters affecting the surface form properties in the ductile stainless steels with gray relational analysis method. Gazi Univ Sci J: Part:C ‘Design Technol 6:634–643. https://doi.org/10.29109/gujsc.395667

Gökçe H (2019) Optimization of cutting tool and cutting parameters in face milling of custom 450 through the Taguchi method. Adv Mater Sci Eng 1:11. https://doi.org/10.1155/2019/5868132

Basmacı G (2018) Optimization of processing parameters of AISI 316 Ti stainless steels. Academic Platform J Eng Sci 6(3):01–07. https://doi.org/10.21541/apjes.422606

Darwin JD, Lal DM, Nagarajan G (2008) Optimization of cryogenic treatment to maximize the wear resistance of 18%Cr martensitic stainless steel. J Mater Process Technol 195:241–247. https://doi.org/10.1016/j.jmatprotec.2007.05.005

Outeiro JC, Umbrello D, M'Saoubi R (2006) Experimental and numerical modelling of the residual stresses induced in orthogonal cutting of AISI 316L steel. Int J Mach Tools Manuf 46:1786–1794. https://doi.org/10.1016/j.ijmachtools.2005.11.013

Carpenter Technology Corp (2009) Techical Datasheet Custom 450 ® Stainless https://www.spacematdb.com/spacemat/manudatasheets/custom%20450.pdf; [accessed 20 December 2020]

Uysal A (2017) Investigation of cutting temperature in minimum quantity lubrication milling of ferritic stainless steel by using multi wall carbon nanotube reinforced cutting fluid. J Faculty Eng Architect Gazi Univ 32(3):645–650. https://doi.org/10.17341/gazimmfd.337612

Özbek NA, Çiçek A, Gülesin M, Özbek O (2017) Evaluation of Machinability of AISI 304 and AISI 316 Austenitic Stainless Steels. J Polytechnic 20(1):43–49. https://doi.org/10.31202/ecjse.67151

Tekaslan Ö, Gerger N, Şeker U (2008) AISI 304 östenitik paslanmaz çeliklerde kesme parametrelerine bağlı olarak yüzey pürüzlülüklerinin araştırılması. Balıkesir Üniversitesi FBE Dergisi 10(2):3–12

Ahmed YS, Youssef H, El-Hofy H, Ahmed M (2018) Prediction and optimization of drilling parameters in drilling of AISI 304 and AISI 2205 steels with PVD monolayer and multilayer coated drills. J Manufact Mater Process 2:1–16. https://doi.org/10.3390/jmmp2010016

Carpenter Technology Corp Techical Datasheet Custom 450 ® Stainless, UNS S45000 https://www.ulbrich.com/uploads/data-sheets/Custom-450-Stainless-Steel-Wire-UNS-S45000.pdf; 2015 [accessed 20 December 2020]

Gökçe H, Yavuz M, Karayel M (2017) Dynamometer design and manufacturing for cutting force definition on machining process. Gazi J Eng Sci (GJES) 3(2):27–32

Kökçam AH, Uygun Ö, Kılıçaslan E (2018) Optimum Tire Selection with Grey Relational Analysis. J Intell Syst: Theory Appl (JISTA) 1(1):31–35. https://doi.org/10.38016/jista.452996

Deng JL (1982) Grey system fundamental method. Huazhong University of Science and Technology, Wuhan

Feng CM, Wang RT (2000) Performance evaluation for airlines ıncluding the consideration of financial ratios. J Air Transp Manag 6:133–142. https://doi.org/10.1016/S0969-6997(00)00003-X

Kuo Y, Yang T, Huang GW (2008) The use of grey relational analysis in solving multiple attribute decisionmaking problems. Comput Ind Eng 55(1):80–93. https://doi.org/10.1016/j.cie.2007.12.002

Peker İ, Baki B (2011) Gri ilişkisel analiz yöntemiyle türk sigortacılık sektöründe performans ölçümü. Int J Econ Administrative Stud 4 (7). ISSN 1307-9832

Köse W, Temiz İ, Erol S (2011) Grey system approach for economic order quantity models under uncertainty. J Grey Syst 23(1):71–82

Yaşar N (2019) Thrust force modelling and surface roughness optimization in drilling of AA-7075: FEM and GRA. J Mech Sci Technol 33:4771–4781. https://doi.org/10.1007/s12206-019-0918-5

Ekici E, Motorcu AR, Uzun G (2017) An investigation of the effects of cutting parameters and graphite reinforcement on quality characteristics during the drilling of Al/10B4C composites. Measurement 95:395–404. https://doi.org/10.1016/j.measurement.2016.10.041

Uzun G, Gökmen U, Çinici H, Türker M (2017) Effect of cutting parameters on the drilling of AISI7 metallic foams. Materiali and technologije 51(1):19–24. https://doi.org/10.17222/mit.2015.106

Agapiou JS, DeVries MF (1990) On the determination of thermal phenomena during drilling-part II. Comparison of experimental and analytical twist drill temperature distributions. Manufacture 30(2):217–226. https://doi.org/10.1016/0890-6955(90)90131-2

Çakıroğlu R, Acır A (2013) Taguchi optimization method of tool chip interface temperature depending on the cutting parameters in drilling operations. Electronic J MachineTechnol 10(2):73–86

Bücker M, Oezkaya E, Hensler U, Biermann D (2020) A new flank face design leading to an ımproved process performance when drilling high-temperature nickel-base alloys. MIC Procedia, 020–026, 20th Machining Innovations Conference for Aerospace Industry 2020 (MIC 2020), December 2nd 2020, Hannover, Germany

Uzun G, Yaşar SA, Korkut İ (2017) Investigation of the effect of cutting parameters on cutting force and hole quality of Ti-6Al-4V alloy in drilling. Karaelmas Sci Eng J 7(2):469–475

Acknowledgements

The author would like to thank Çankırı Karatekin University Scientific Research Project Unit for provision of funding with the Project MYO801202B33.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gökçe, H. Modelling and Optimization for Thrust Force, Temperature and Burr Height in Drilling of Custom 450. Exp Tech 46, 707–721 (2022). https://doi.org/10.1007/s40799-021-00510-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40799-021-00510-z